Patents

Literature

45 results about "Thermo gravimetric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermo Gravimetric Analysis (TGA) Thermo Gravimetric Analysis (TGA) is a thermal analysis technique used to measure changes in the weight (mass) of a sample as a function of temperature and/or time.

Method for evaluating drilling fluids

InactiveUS6009747AEffectively minimize borehole stability problemsWeighing by removing componentFlow propertiesWell drillingDrilling fluid

A method for evaluating drilling fluids to be used with clay-rich rocks such as shales which comprises collecting shales so as to preserve the downhole hydration condition and then submitting such preserved shale to Thermo-Gravimetric Analysis, so as to obtain the derivative curve of mass with respect to temperature, then immersing a sample of the same piece of rock in the drilling fluid of which the interaction with the clay-rich rock is to be ascertained and obtaining TGA analysis at successive periods of time of immersion of the sample, so as to determine the modifications undergone by the sample immersed in the drillling fluid. From the modifications undergone by the sample it is possible to evaluate the adequacy of the drilling fluid to be contacted with the clay-rich rock.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

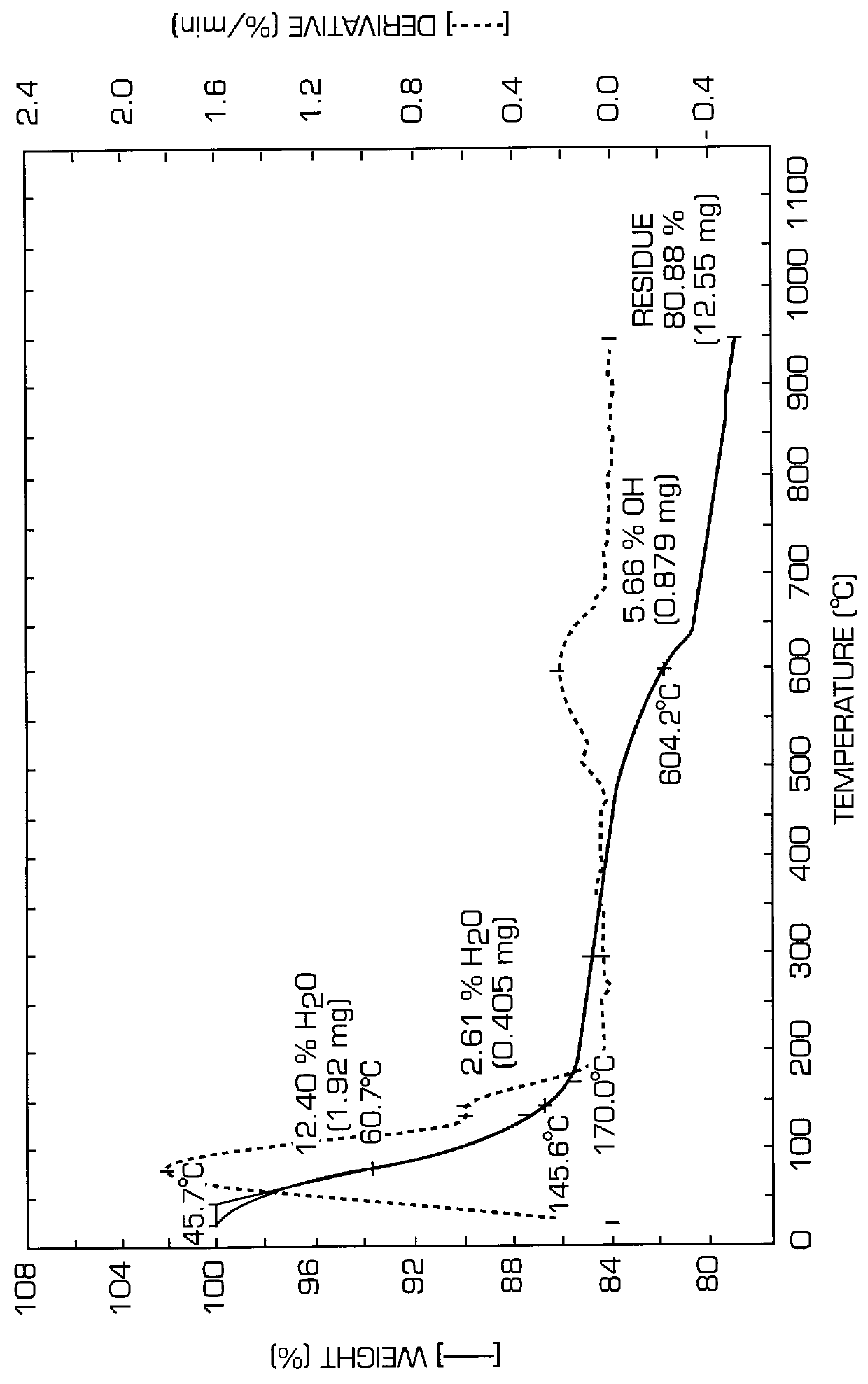

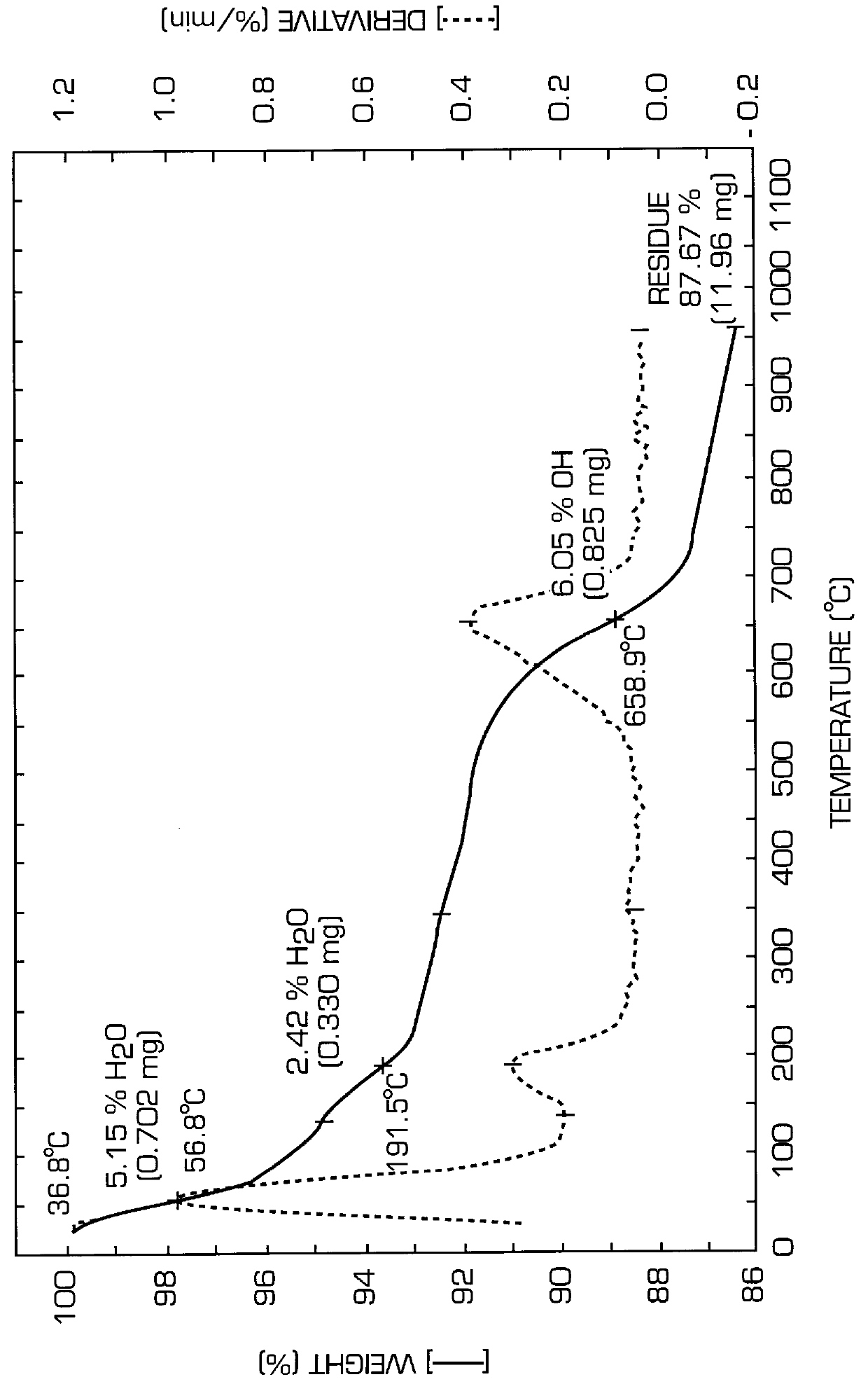

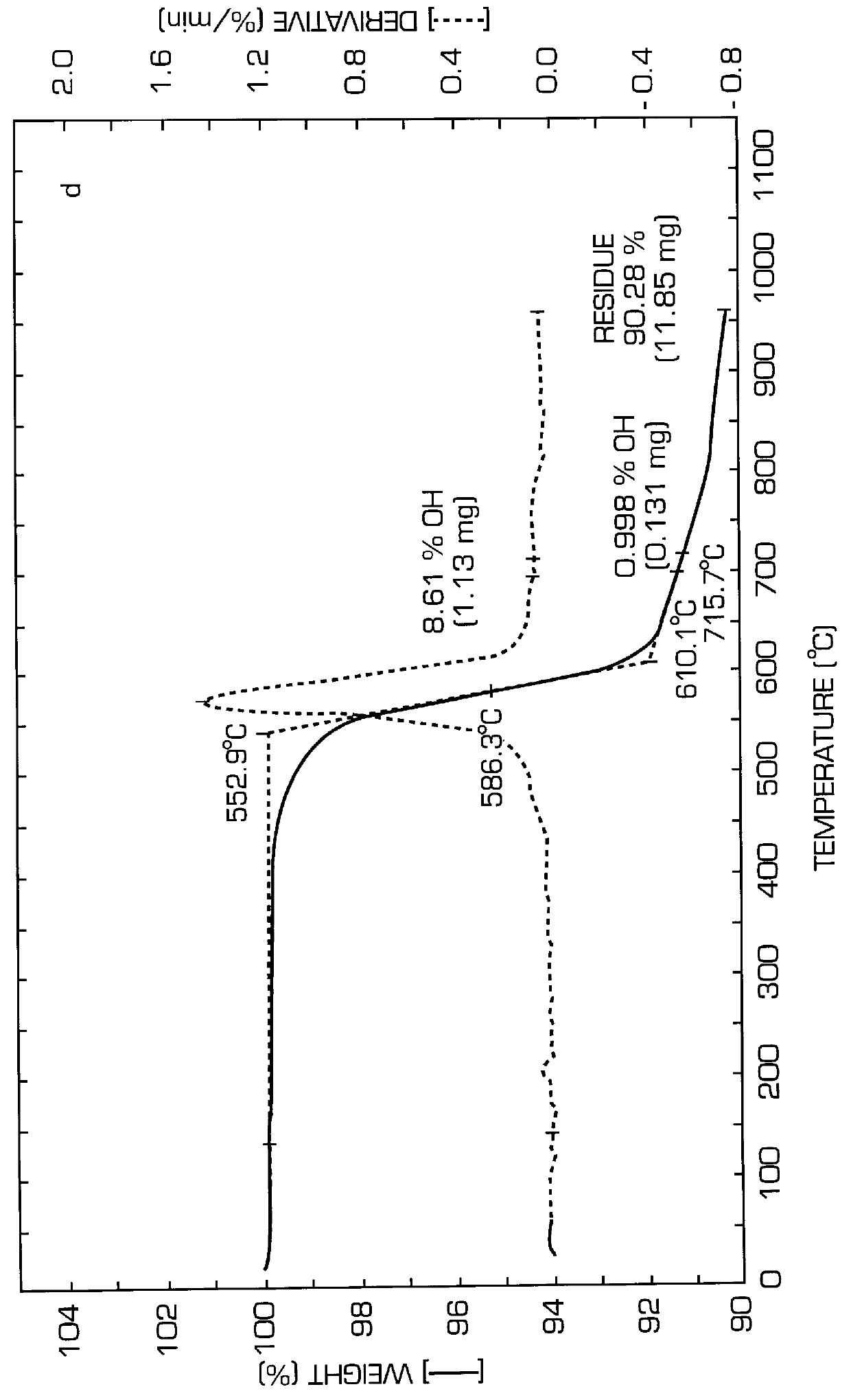

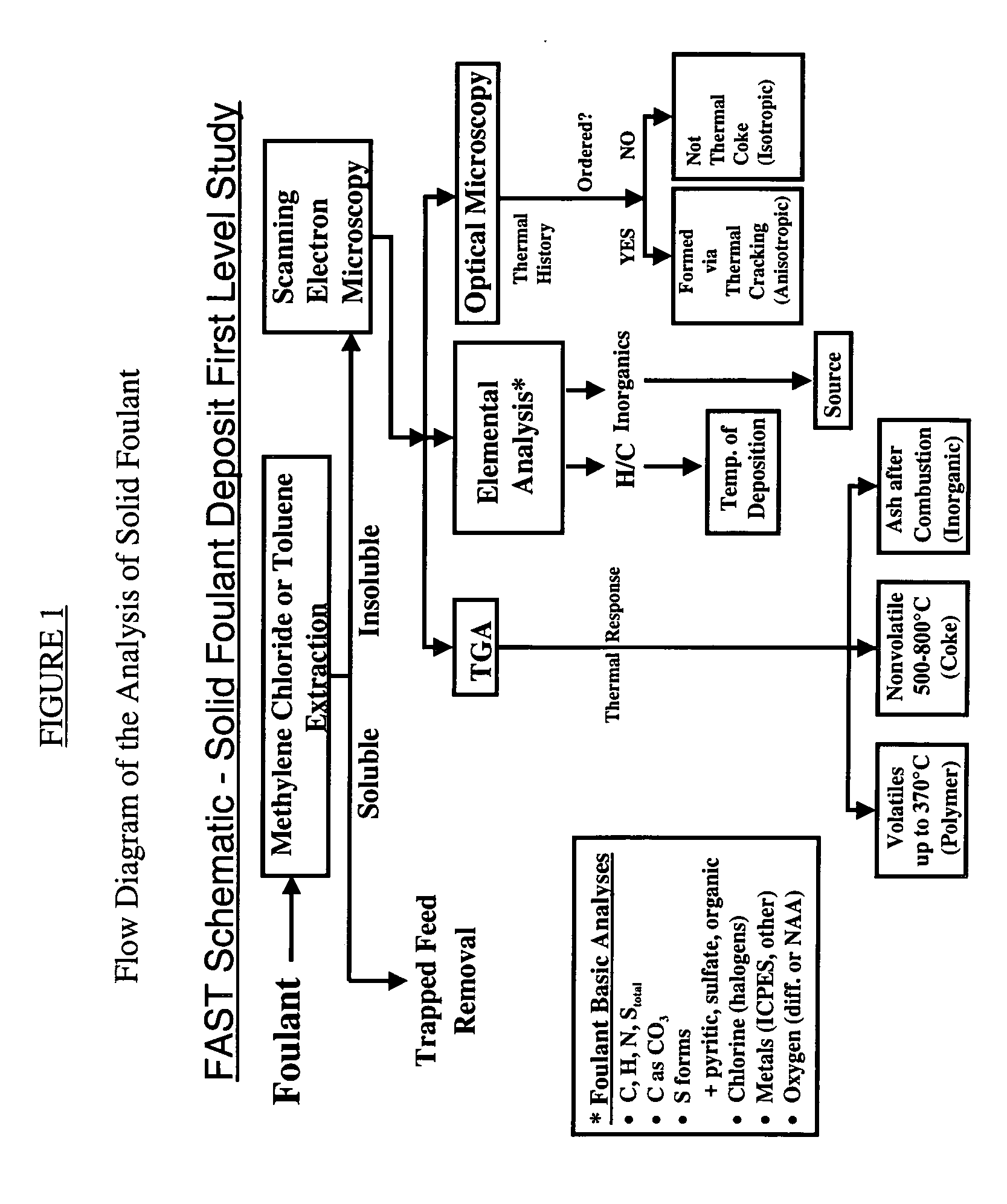

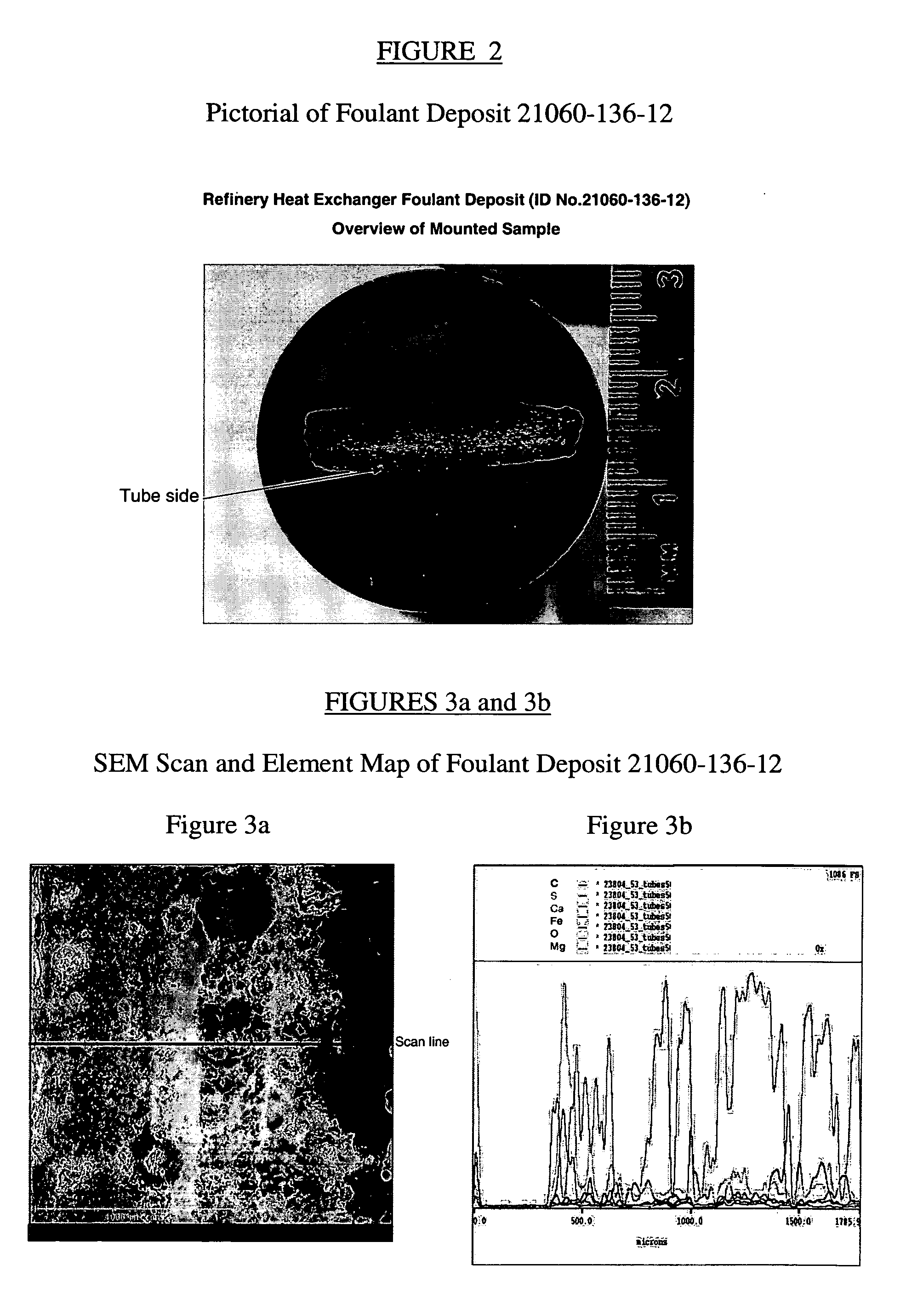

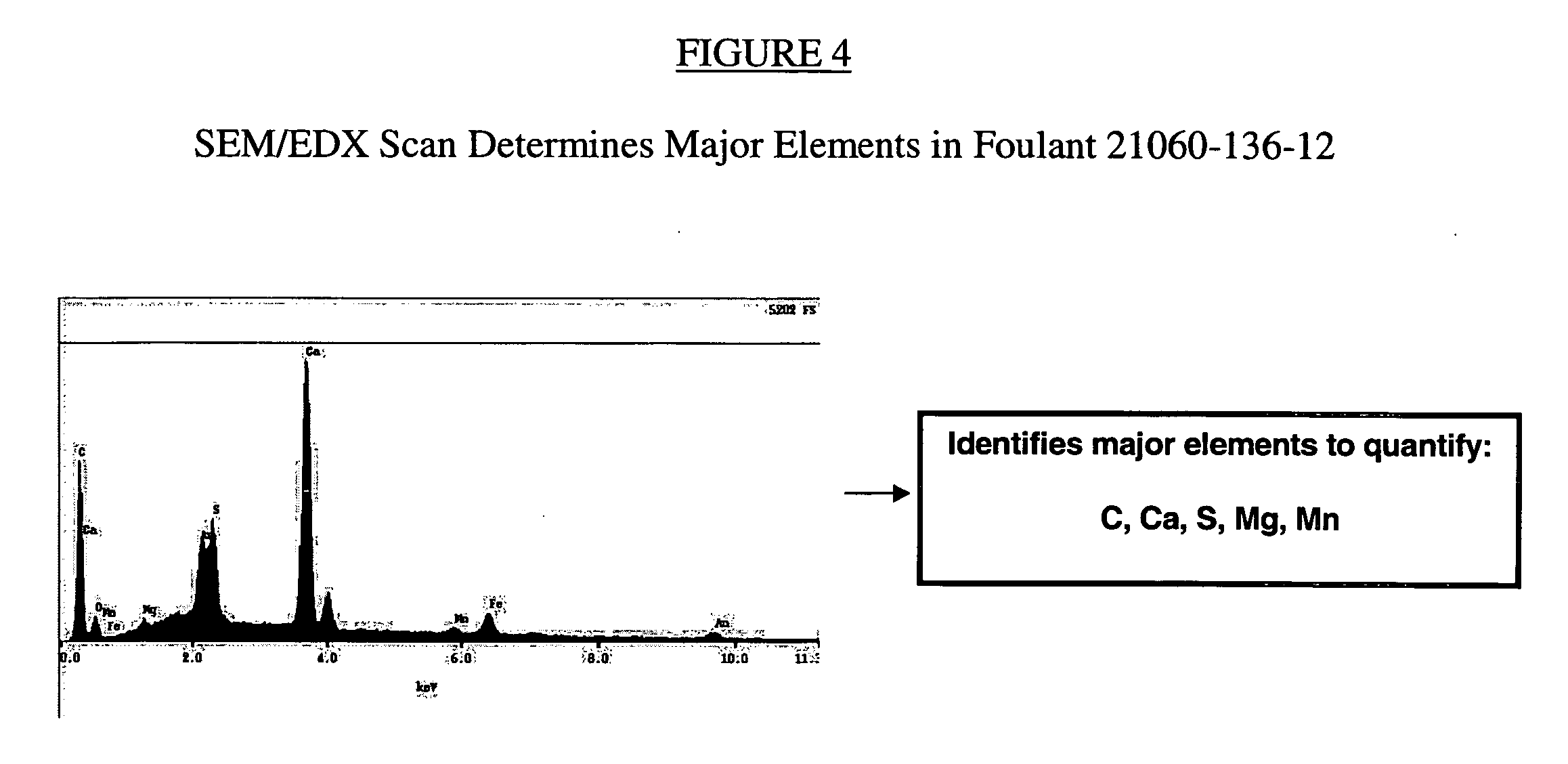

Method for refinery foulant deposit characterization

The present invention is a method to identify a refinery solid foulant of unknown composition including the following steps: obtaining a solid foulant sample, removing trapped feed from the sample with a solvent to obtain an insoluble sample, scanning the insoluble sample with a scanning electron microscope and energy dispersive x-rays, performing a thermal gravimetric analysis including an ash test on the insoluble sample to determine the presence of polymer, coke and inorganic elements, performing an elemental analysis on the insoluble sample for the elements carbon, hydrogen, sulfur, nitrogen, halogens, and metals, performing an optical microscopy on the insoluble sample to determine the presence of wax, asphaltenes, anisotropic coke and isotropic coke, and identifying the solid foulant.

Owner:EXXON RES & ENG CO

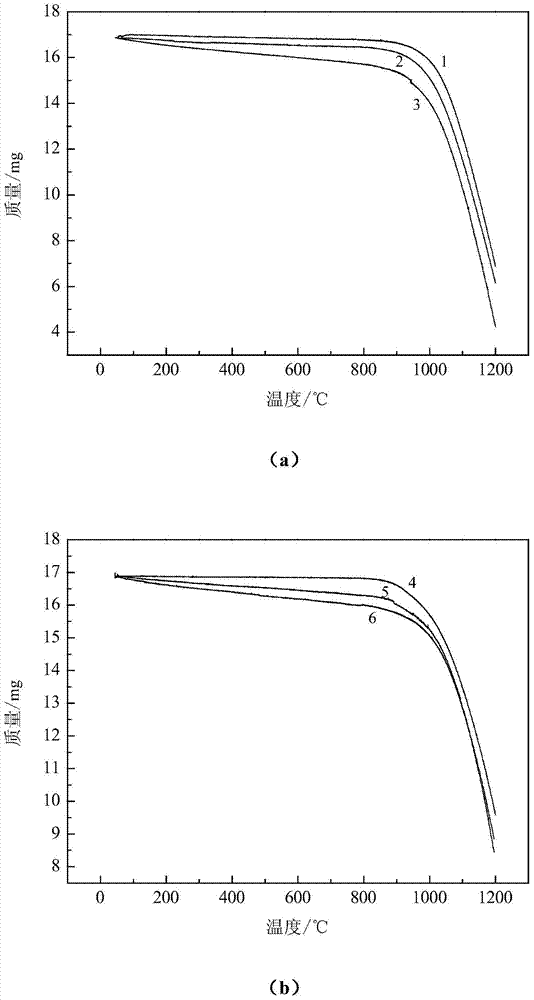

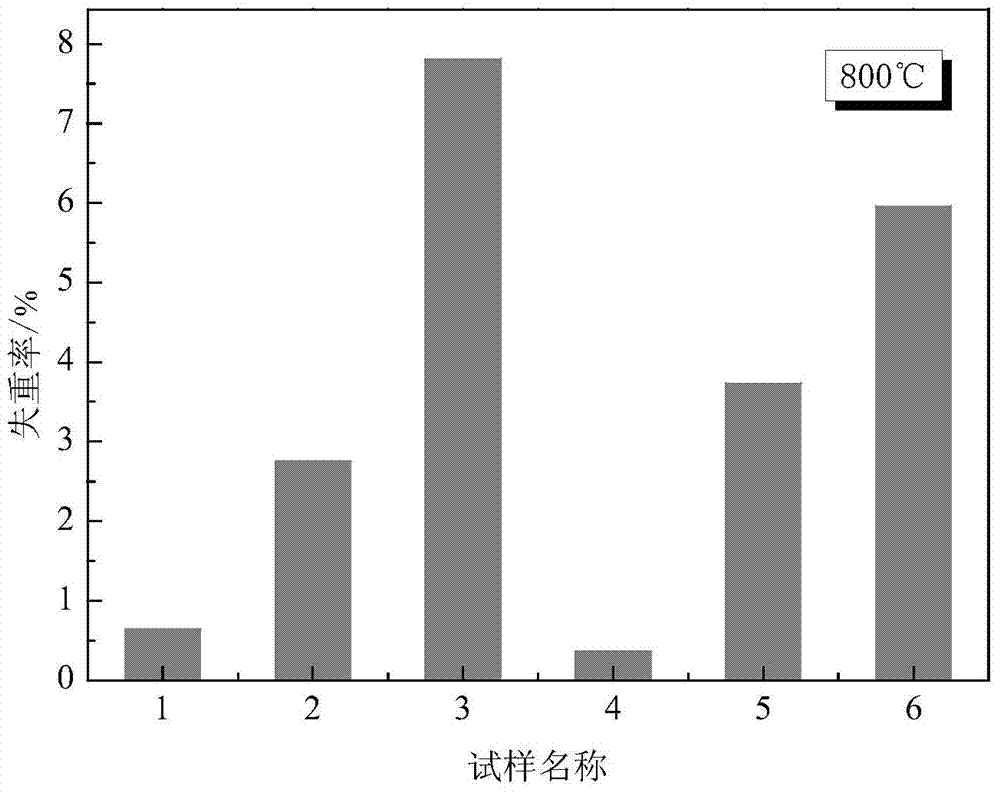

Test method for blast furnace coke reactivity

ActiveCN103940697AReduce usageAvoid deviations caused by different reaction ratesWeighing by removing componentPhysical chemistryData acquisition

The invention provides a test method for blast furnace coke reactivity. According to the method, conventional equipment is utilized, by obtaining the weight loss rate variation of coke at different temperature and the initial temperature of the carbon solution loss reaction of coke, the reactivity of coke is characterized. The method comprises: grinding a selected to-be tested coke sample into fine powder, drying, taking out the coke sample, cooling to room temperature, sealing for usage; weighing the coke sample for usage, putting in a test apparatus, continuously raising the temperature, introducing a reaction gas CO2, when the heating terminal point is reached, finishing computer data acquisition, and storing the acquisition data; finally processing the data acquired by a computer; and finally characterizing the reactivity of coke by obtaining the weight loss rate variation of coke at different temperature and the initial temperature of the carbon solution loss reaction of coke. According to the method, test equipment such as a thermo gravimetric analyzer and the like are employed, the reaction situation of coke with CO2 at different temperature can be comprehensively analyzed, and true objective evaluation on the reactivity of cokes with different quality can be made.

Owner:UNIV OF SCI & TECH BEIJING

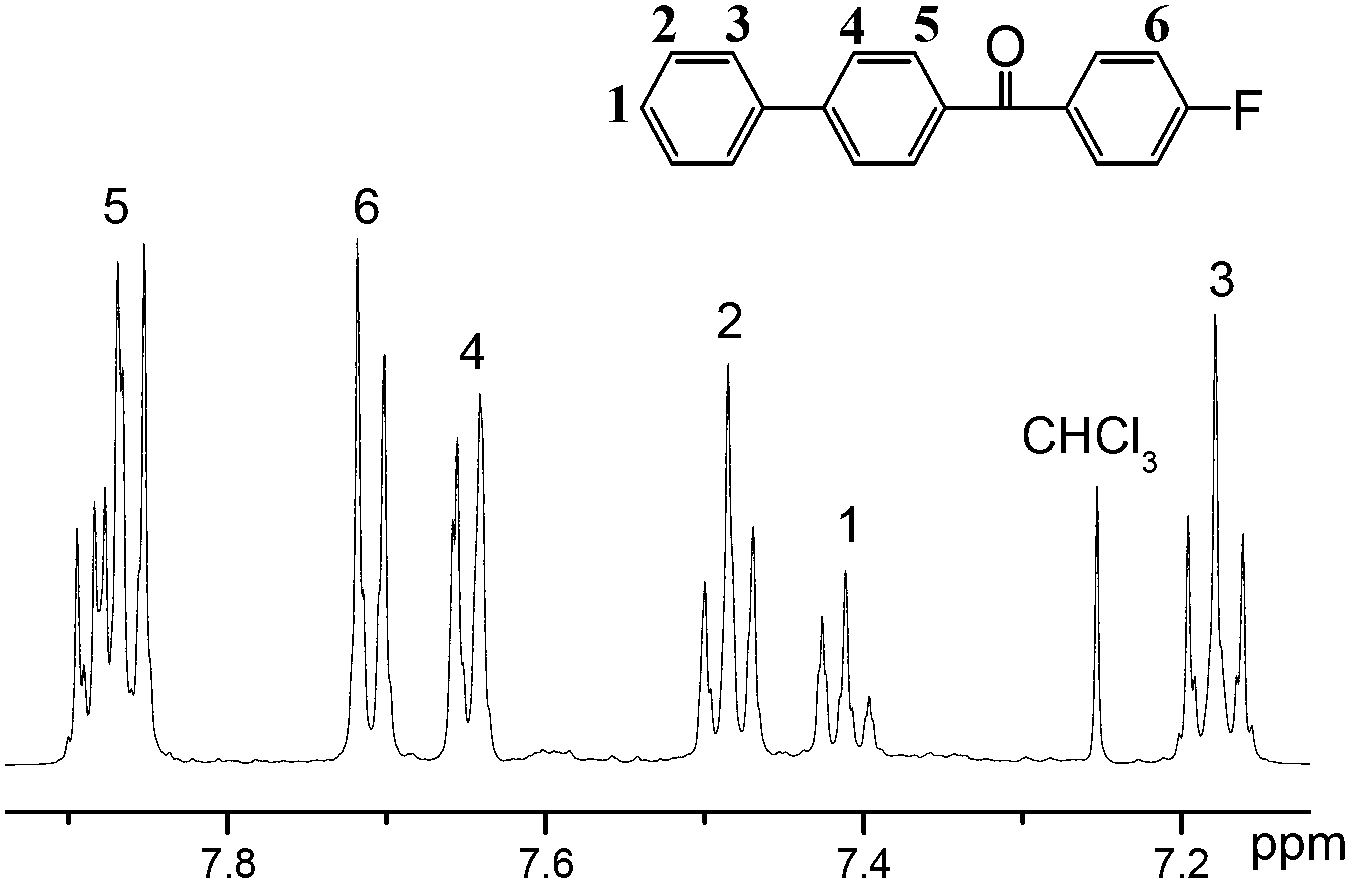

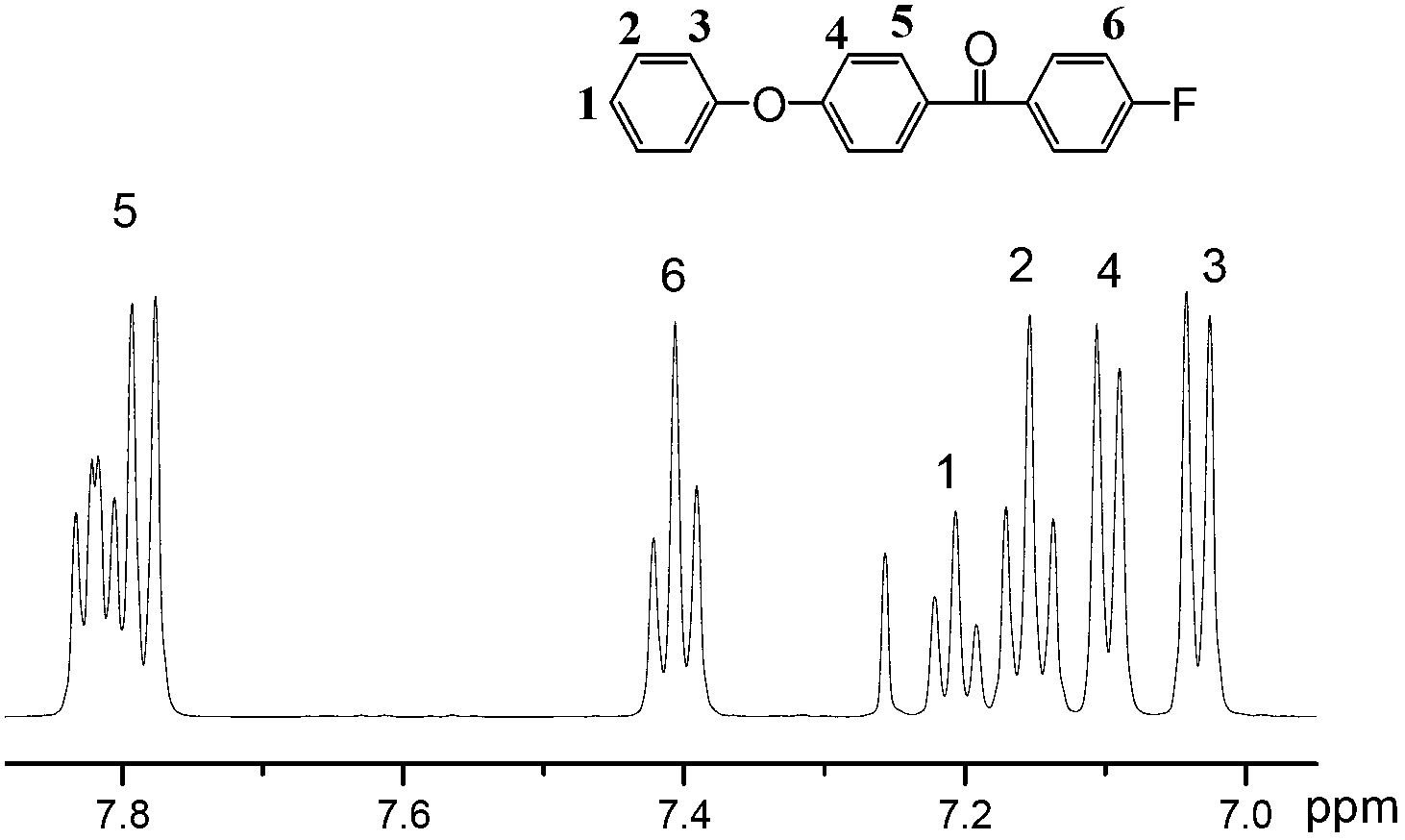

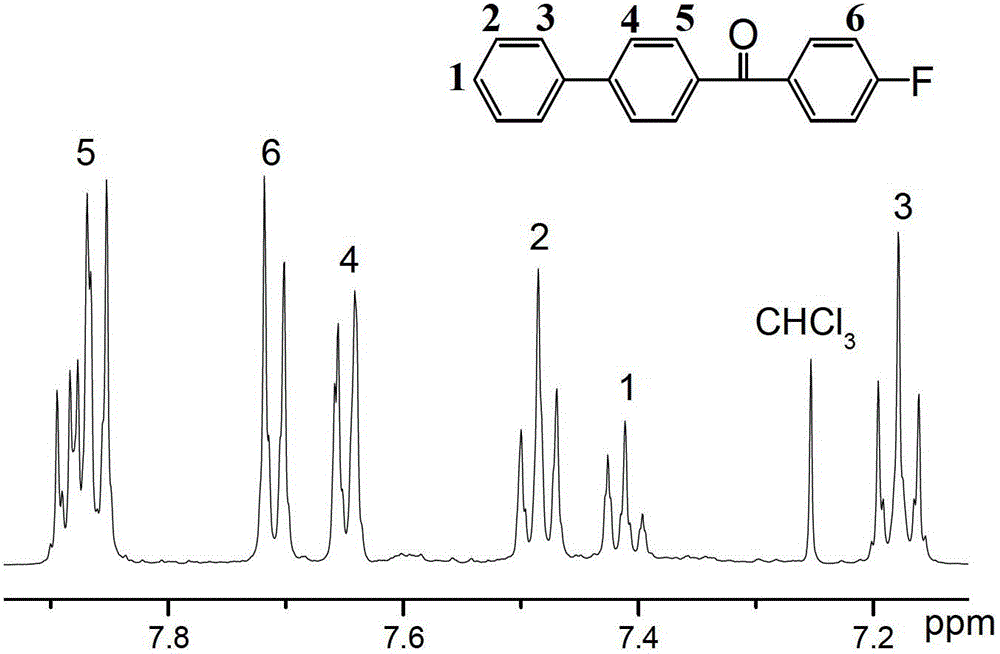

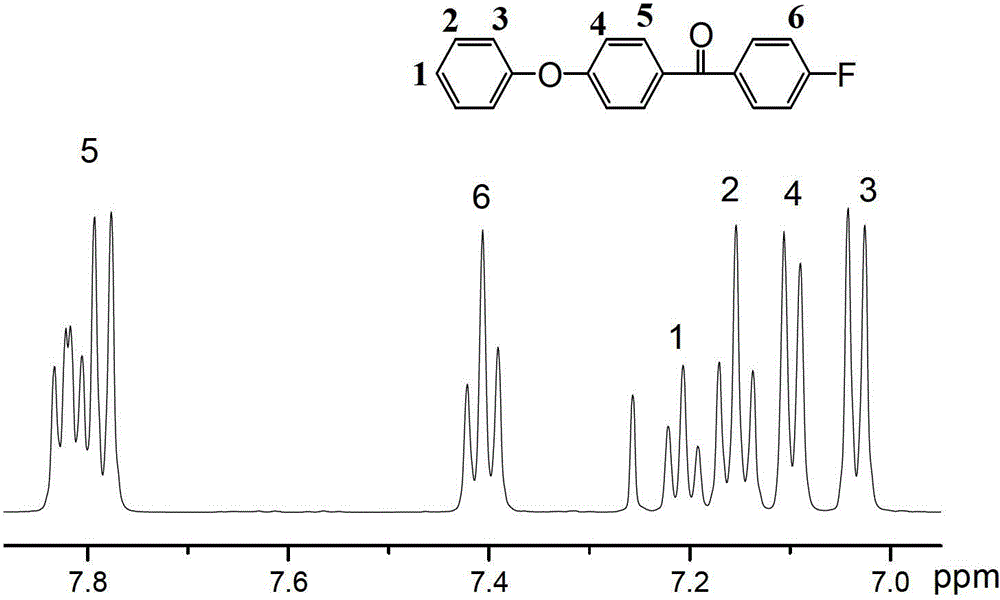

Method for preparing benzene end-capping polyaryletherketone polyme

ActiveCN102702459AAddress reactivitySolve technical problemsOrganic compound preparationCarbonyl compound preparation by condensationChemical reactionPhenyl Ethers

The invention relates to a method for preparing benzene end-capping polyaryletherketone polymers, which belongs to the technical field of high polymer materials. The preparation method comprises the steps as follows: using 4-(p fluorophenyl acyl) biphenyl or 4-(p fluorophenyl acyl) phenyl ether as an end-capping agent, using 4,4'-difluorobenzophenone and a bisphenol monomer as reactants, and using a nucleophilic route to prepare the benzene end-capping polyaryletherketone polymers with glass transition temperature of 147 DEG C and initial thermo-gravimetric temperature above 540 DEG C. Two detailed chemical equations describing the preparation process are attached. With two end-capping monomers having boiling points above 320 DEG C and suitable process conditions, the method for preparing the benzene end-capping polyaryletherketone polymers solves the technical problem caused by the fact that the p fluorophenyl acyl has low boiling point and volatilizes in an end-capping reaction in the prior art, and synthetizes polyaryletherketone with a benzene oxygen end group and polyaryletherketone with a biphenyl end group, so as to meet the requirement of continuous industrial production.

Owner:山东君昊高性能聚合物有限公司

Polyimide adhesive

InactiveCN102618206AExcellent bond strength changeSmall bond strength changesAdhesivesThermal ageingAdhesive

A polyimide adhesive relates to an adhesive and aims at solving problems that the existing polyimide structural adhesive is poor in toughness and decreasing in viscosity and strength is apt to occur in the storing process. The polyimide adhesive is composed of polyimide carrier membranes and polyamide acid primers which are independently packaged. The polyimide adhesive has the advantages that shearing strength at room temperature is 18MPa-22MPa, shearing strength at temperature of 320 DEG C is 10MPa-16MPa, peeling strength at temperature of 90 DEG C is 2kN / m-4kN / m, glass-transition temperature is larger than 300 DEG C, and 5% thermo-gravimetric temperature is larger than 520 DEG C; and bonding strength change is smaller than 5% after thermal ageing at temperature of 300 DEG C after 160 hours, and the polyimide adhesive is suitable for being used as a high temperature structural adhesive. The polyimide adhesive is mainly used for polyimide adhesive preparing.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

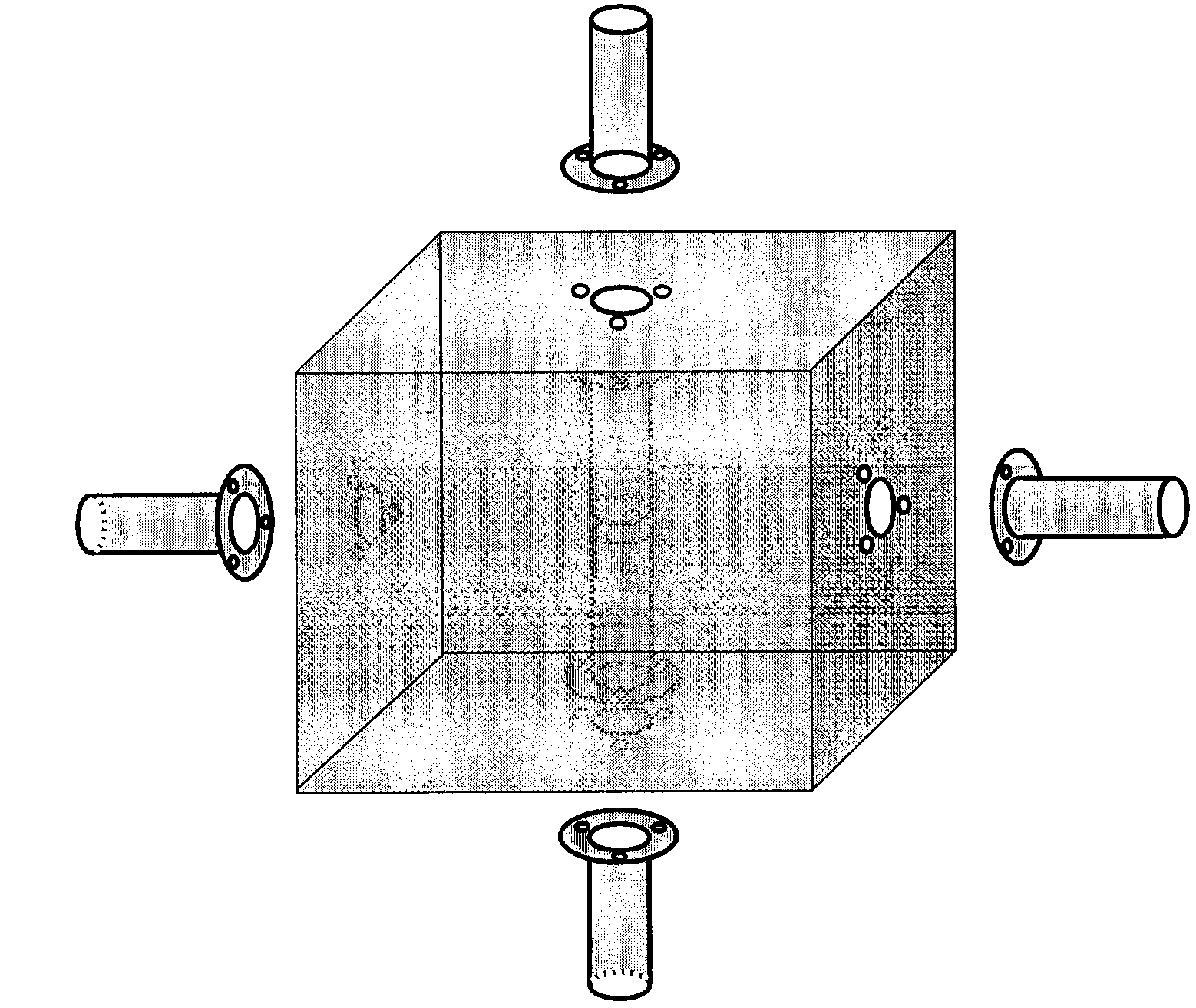

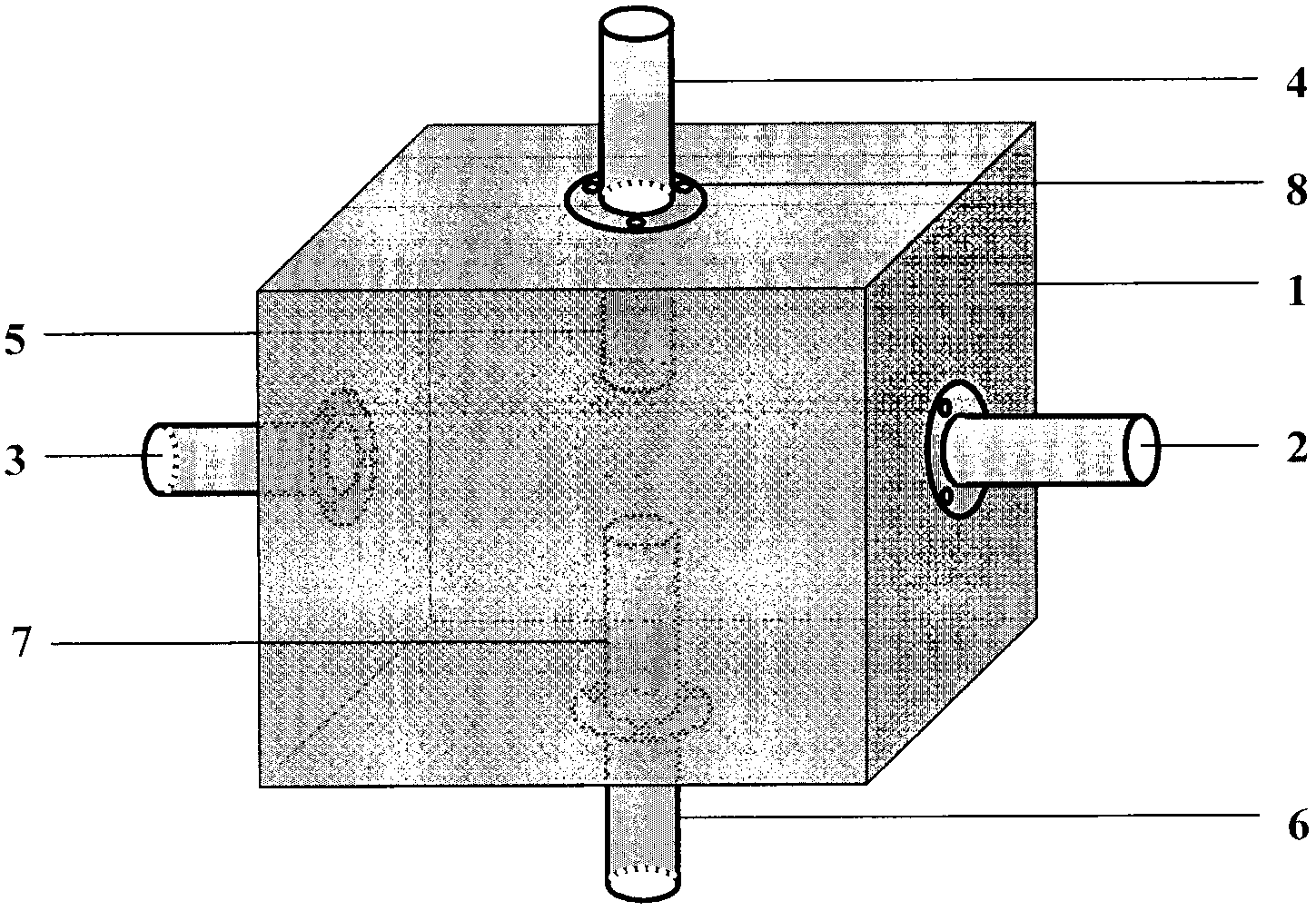

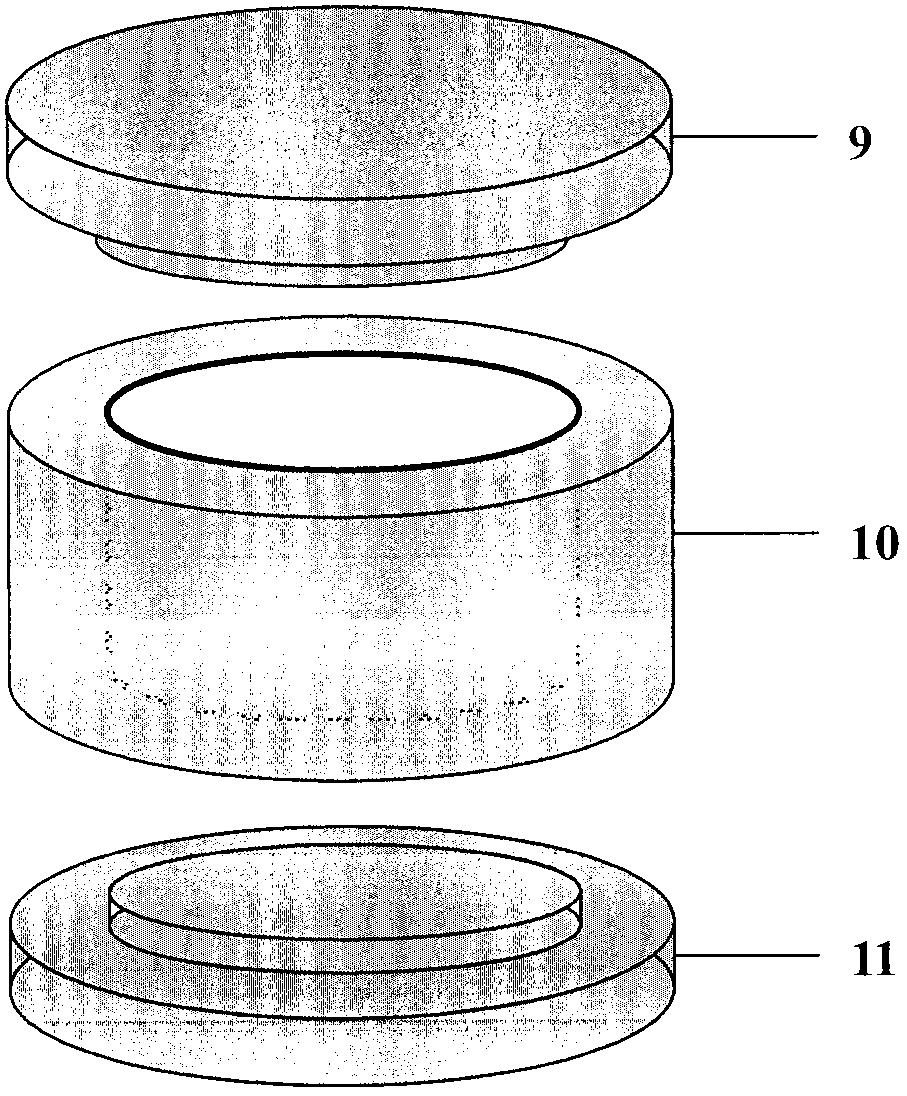

Microwave material science workstation

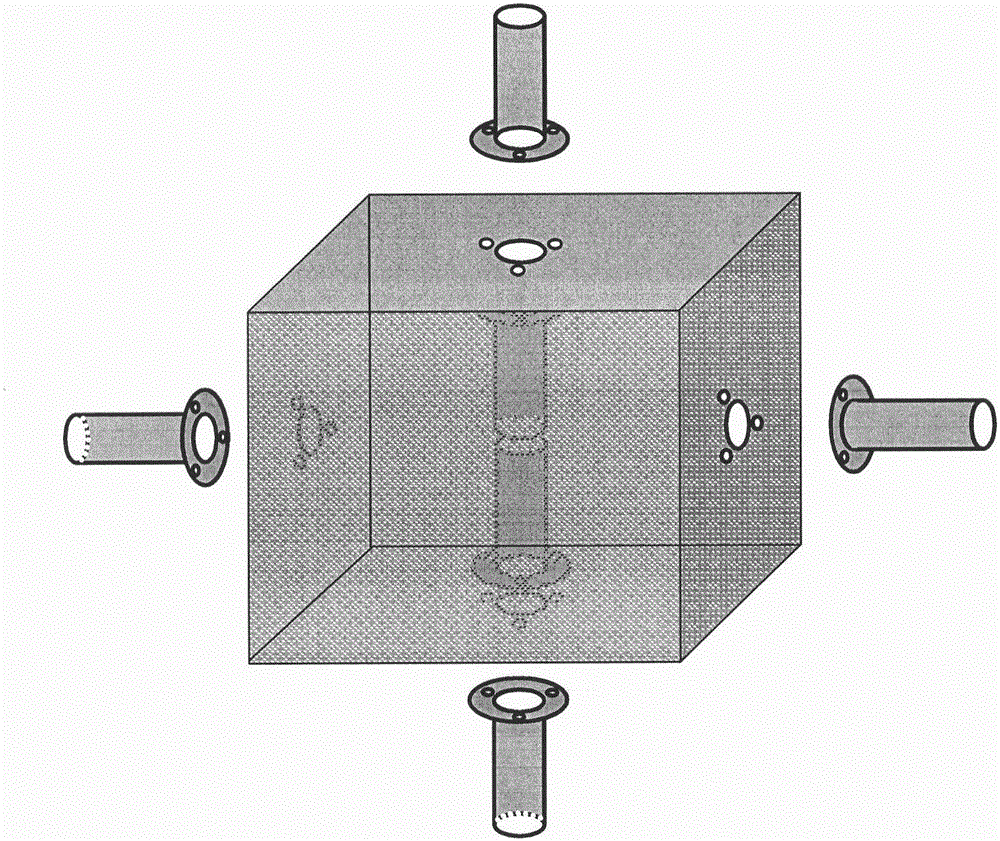

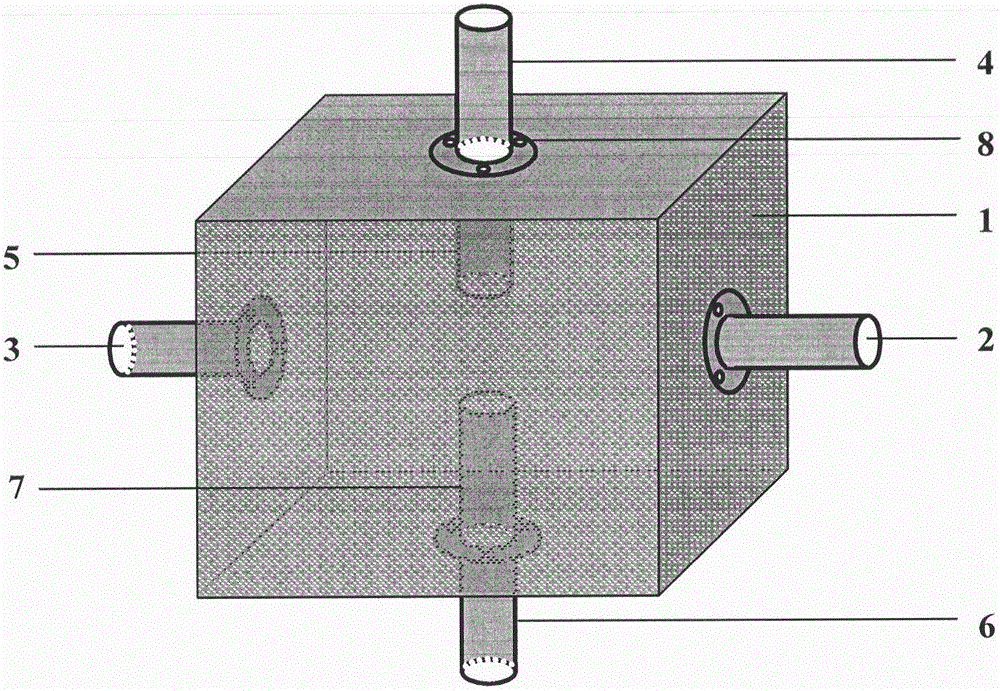

The invention discloses a microwave material science workstation, which belongs to the technical field of the microwave heating. The microwave material science workstation mainly consists of a sealed microwave metal cavity, a functional interface, a function modularization heating cavity, a microwave generation and control system, a temperature control system and a cooling system. The microwave material science workstation adopts three heating modes, namely pure microwave heating, traditional electric heating and mixed heating and contains or develops various functions by the functional interface, i.e. functions of a muffle furnace, a tube furnace, a chemical reactor, a microwave digestion instrument, an in-situ thermo gravimetric analyzer, a kinetic analysis instrument, a microwave electric arc furnace, a multiple temperature zone heating furnace, a high-temperature compression furnace and a stretching furnace, wherein all functional modules are movably connected and movably assembled, and different functional modules are freely changed. The microwave material science workstation with the above characteristics has the advantages of strong function, low cost, remarkable energy saving property, small land occupation and great popularization and application value as well as commercial value, is equivalent to tens of experiment instruments and can be used as a movable material science experiment platform.

Owner:唐山纳源微波热工仪器制造有限公司

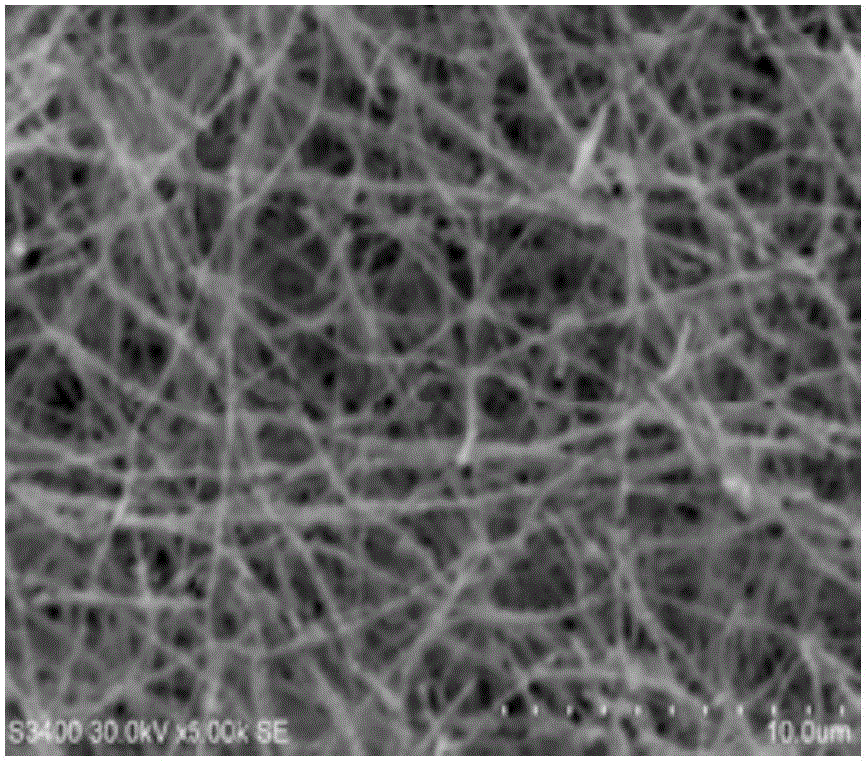

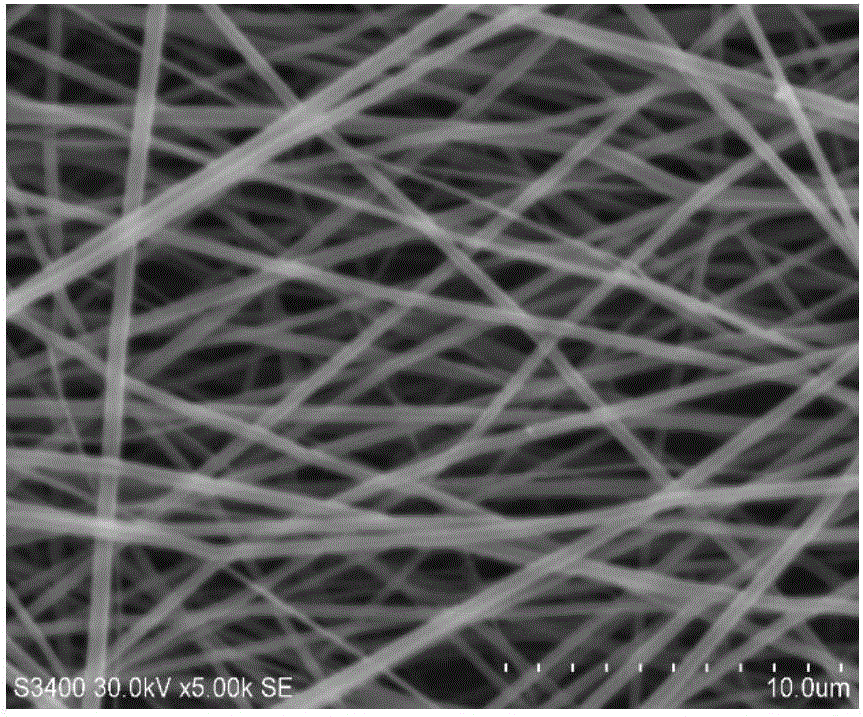

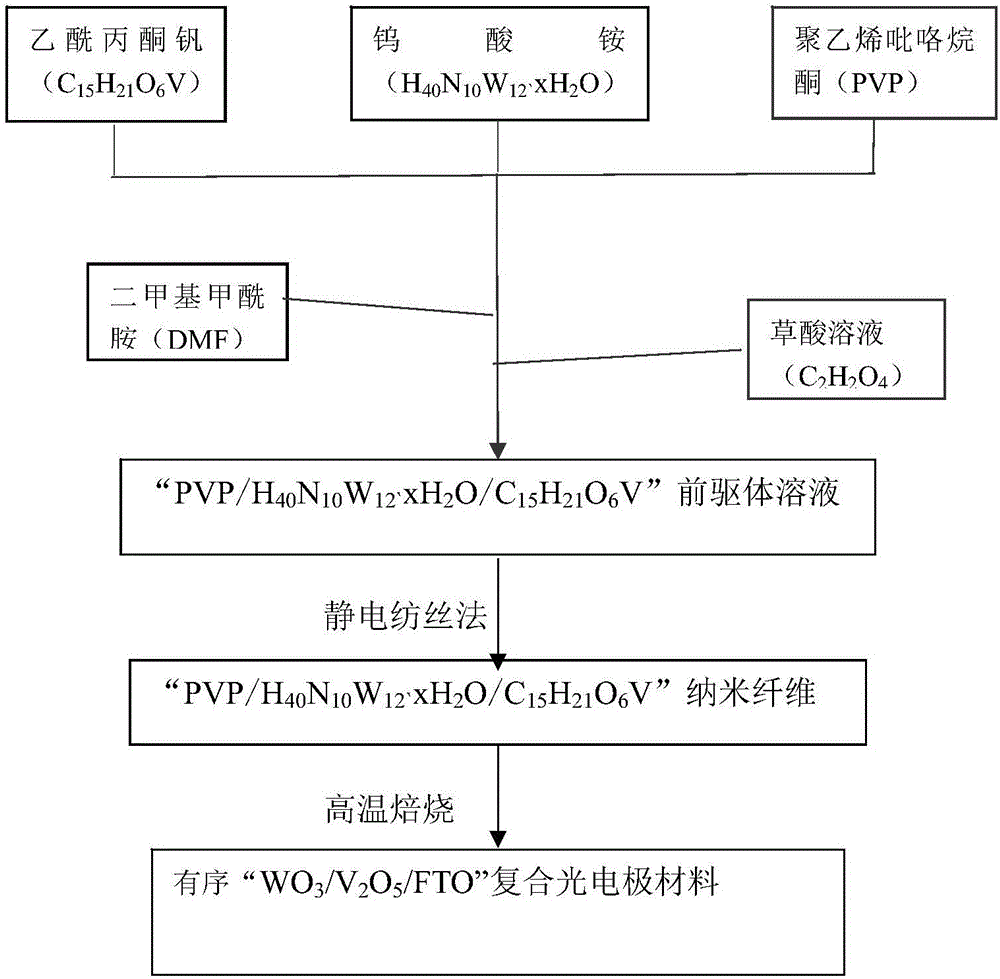

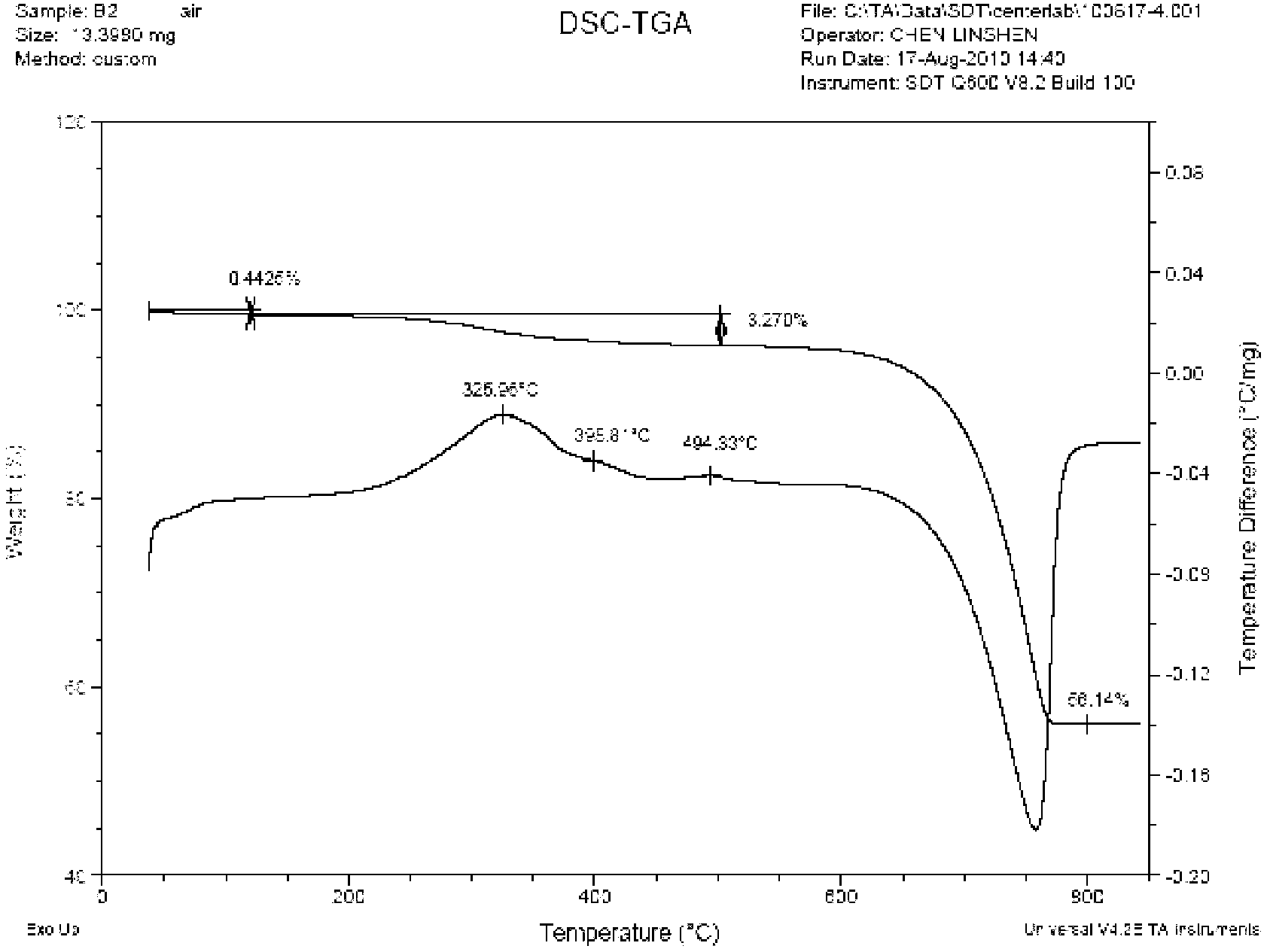

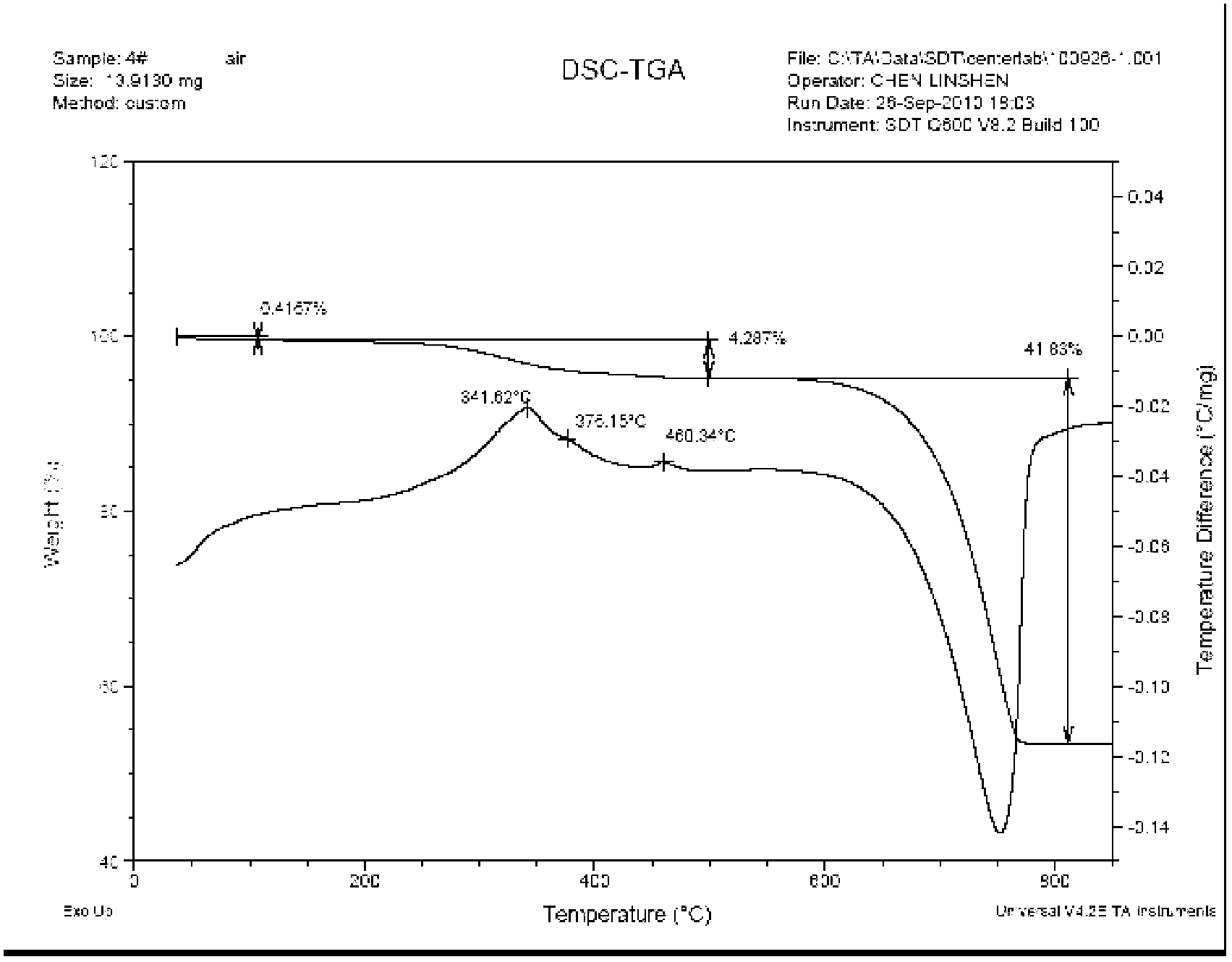

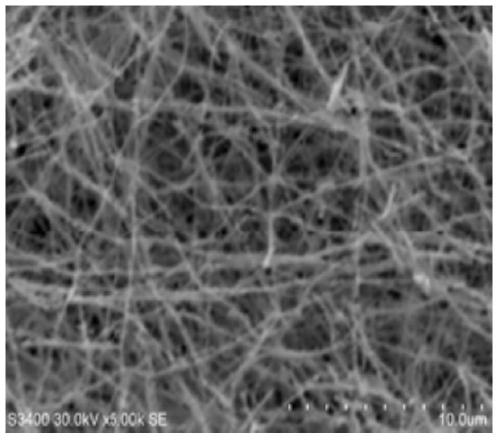

WO3/V2O5/FTO composite photoelectrode as well as preparation and use methods thereof

ActiveCN105923694AEasy reunionResolve separabilityWater/sewage treatment by irradiationInorganic material artificial filamentsMaterials sciencePolyvinylpyrrolidone

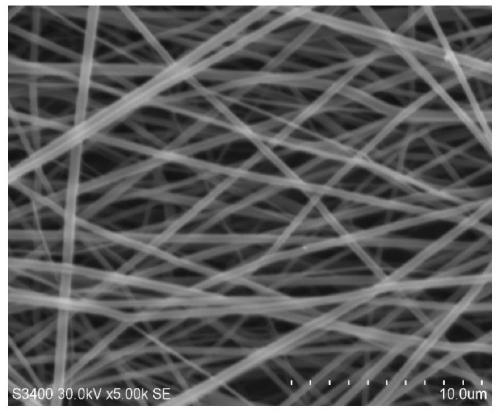

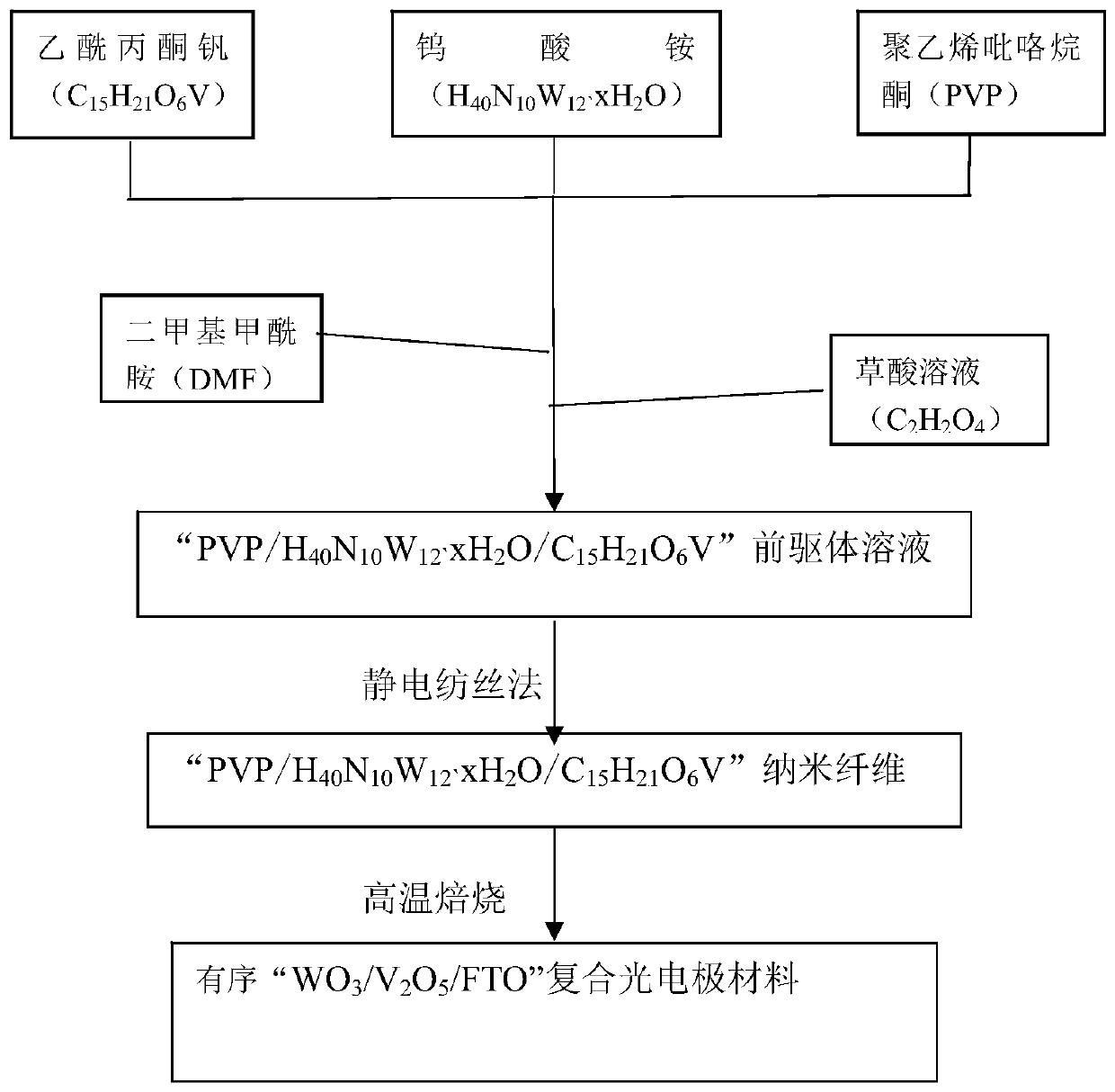

The invention belongs to the field of materials and discloses a method for preparing a conductive glass (FTO)-loaded tungsten trioxide (WO3) / vanadium pentoxide (V2O5) composite photoelectrode (WO3 / V2O5 / FTO). The method comprises the following steps: adopting vanadyl acetylacetonate and ammonium tungstate as raw materials, polyvinylpyrrolidone (PVP) as an auxiliary material, and dimethylformamide (DMF) and oxalic acid solution as solvents; loading a composite precursor onto conductive glass according to an electrostatic spinning technology and finally carrying out high-temperature roasting to obtain a WO3 / V2O5 / FTO composite photoelectrode material with high photo-electro-catalytic activity. The material is characterized through scanning electron microscope (SEM), X-ray diffraction (XRD), thermo-gravimetric-differential thermal analysis (TG-DTA), X-ray photoelectron spectroscopy (XPS), Fourier transform infrared ray spectroscopy (FT-IR) and other means, so that the fiber material obtained by the method disclosed by the invention can be discovered that the release is uniform, and the diameter is 100-150 nm. The WO3 / V2O5 / FTO composite photoelectrode material prepared by adopting the method disclosed by the invention is simple in process and has higher photocatalysis under visible light.

Owner:JISHOU UNIVERSITY

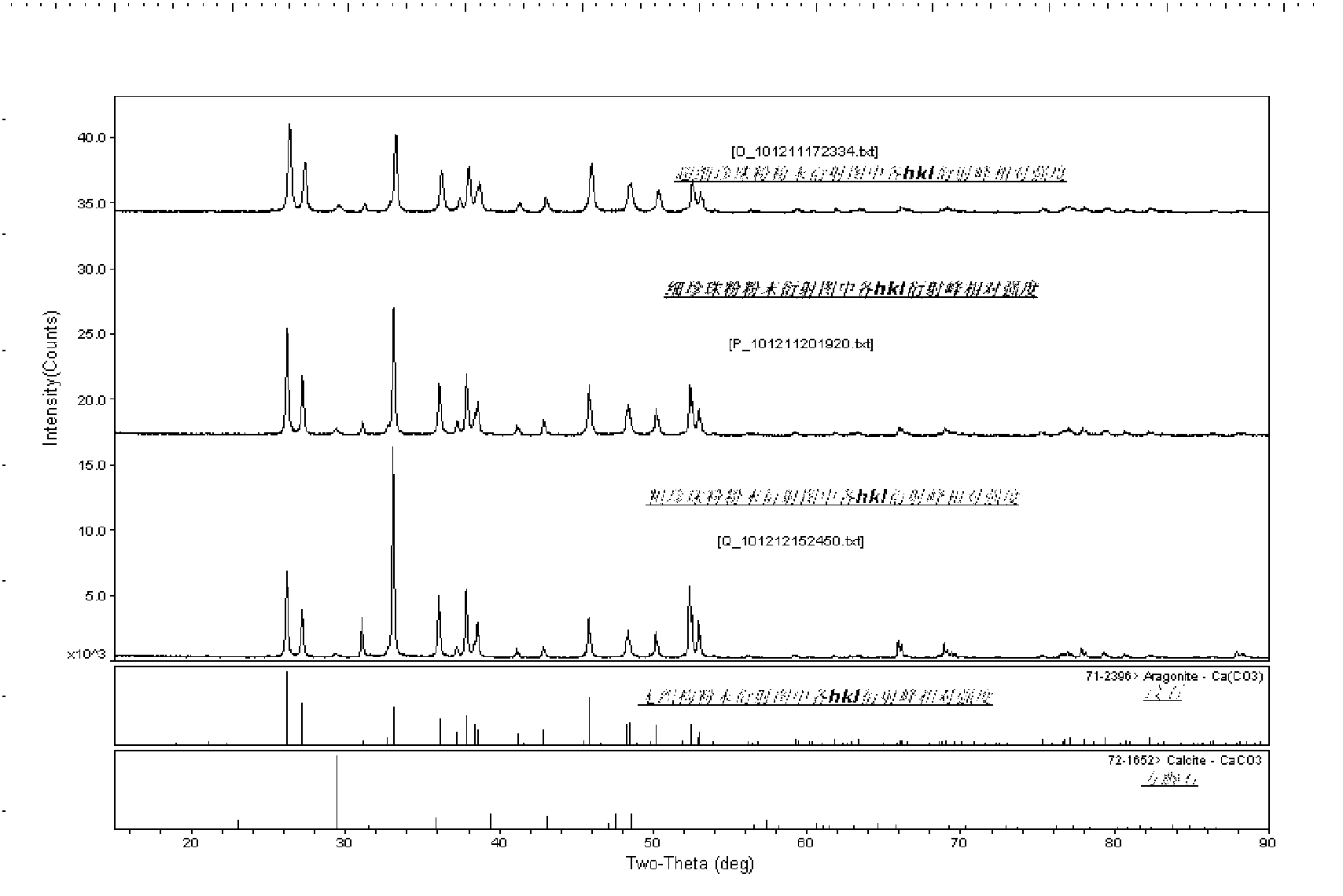

Method for detecting quality of pearl powder by using thermal transformation hemodynamic difference combined with X-ray diffraction (XRD) and application thereof

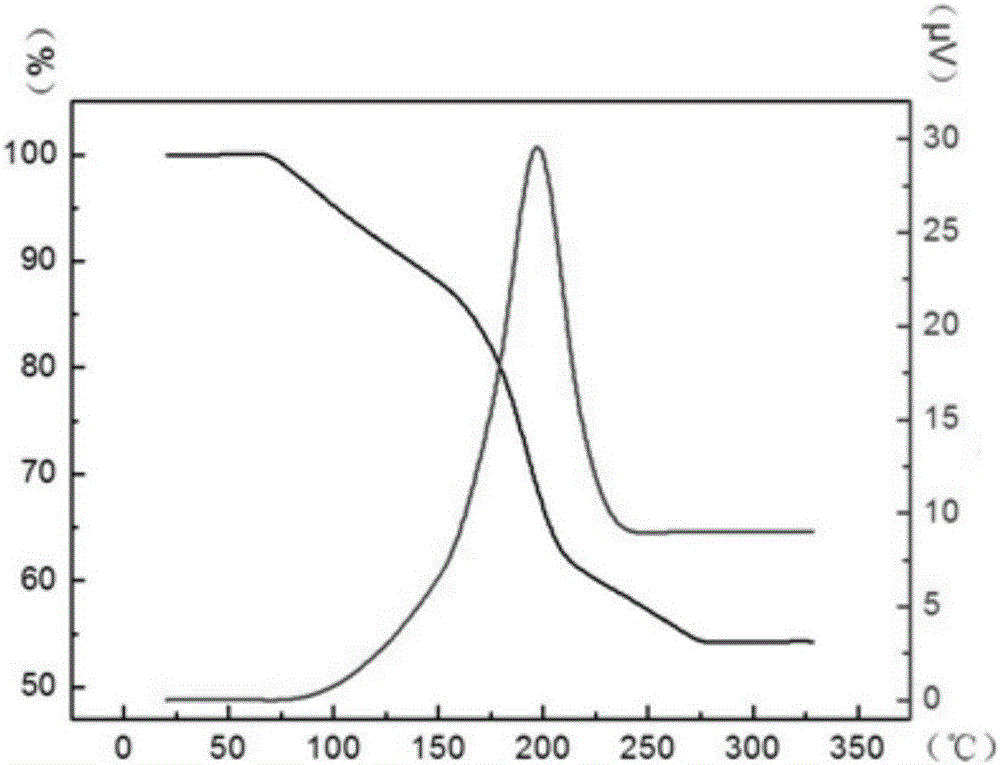

InactiveCN102706911APhase change rate is slowPhase change rate is fastMaterial weighingMaterial analysis using radiation diffractionRoom temperatureX-ray

Owner:浙江华才检测技术有限公司

Phosphor and nitrogen containing flame retardant curing agent, preparation method and application thereof

InactiveCN102432837AImprove flame retardant performanceLow in phosphorusGroup 5/15 element organic compoundsEpoxyGas phase

The invention discloses a phosphor and nitrogen containing flame retardant curing agent, a preparation method and application thereof. The curing agent has a phosphorylurea structure, contains active ammonia and hydrogen atoms, has dual functions of both a flame retarding agent and a curing agent, and can be directly used for curing epoxy resin. In a curing progress, flame retardant elements are embedded into an epoxy structure, thus avoiding phase separation phenomenon due to introduction of additive type flame retarding agent. Phosphor elements mainly function in flame retarding of a condensed phase while a urea structure mainly functions in flame retarding of a gas phase. The curing agent can react with common epoxy resin to obtain uniform and transparent cured object; in addition, the curing agent has low phosphorus content, passes 1.6 mm UL 94 V0 level, reaches oxygen index as high as 29-34%, and has excellent flame retardance; in thermo-gravimetric analysis, the maximum thermal decomposition temperature is as high as 400 DEG C; the char yield of the curing agent at 700 DEG C is 35%; and glass transition temperature of the curing agent is as high as 150 DEG C. The curing agent can also realize co-curing together with common curing agents, such as, diaminodiphenyl sulfone and anhydride-type epoxy curing agents. The curing agent is low in cost, simple in production process, and available for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

Thermo gravimetric analysis method for graphene oxide

ActiveCN105823705AThermogravimetric Analysis ImplementationAccurate Thermogravimetric CurveMaterial weighingAir atmosphereThermo gravimetric

The invention belongs to the technical field of chemical testing and analyzing, and relates to a thermo gravimetric analysis method for graphene oxide .The thermo gravimetric analysis method includes the steps that 1, graphene oxide powder is sieved to be dried to be at the constant weight under the vacuum condition to serve as a sample ready for use; 2, the sample and a powder material are respectively put into a crucible, stirred and mixed, the powder material is formed in the mode that sodium chloride, alumina, quartz, strontium carbonate graphite and / or zirconium dioxide are doped, the mass ratio of the sample to the powder material is 1:0.1-1:100, and after the mixture is stirred to be even, the crucible and another empty crucible are put into a thermo-gravimetry analyzer at the same time; 3, thermo analysis software is started to conduct thermo gravimetric analysis, the heating rate is set to be 5 DEG C / min to 200 DEG C / min, the heating range is set to be at 25 DEG C to 800 DEG C, inert gas or air atmosphere is led to start testing, and therefore thermo gravimetric analysis of the graphene oxide is achieved .The thermo gravimetric analysis method is low in cost, simple in process, scientific in theory, easy to operate, small in required sample number, quick and accurate in testing process and free of pollution and waste.

Owner:QINGDAO HUAGAO GRAPHENE CORP LTD

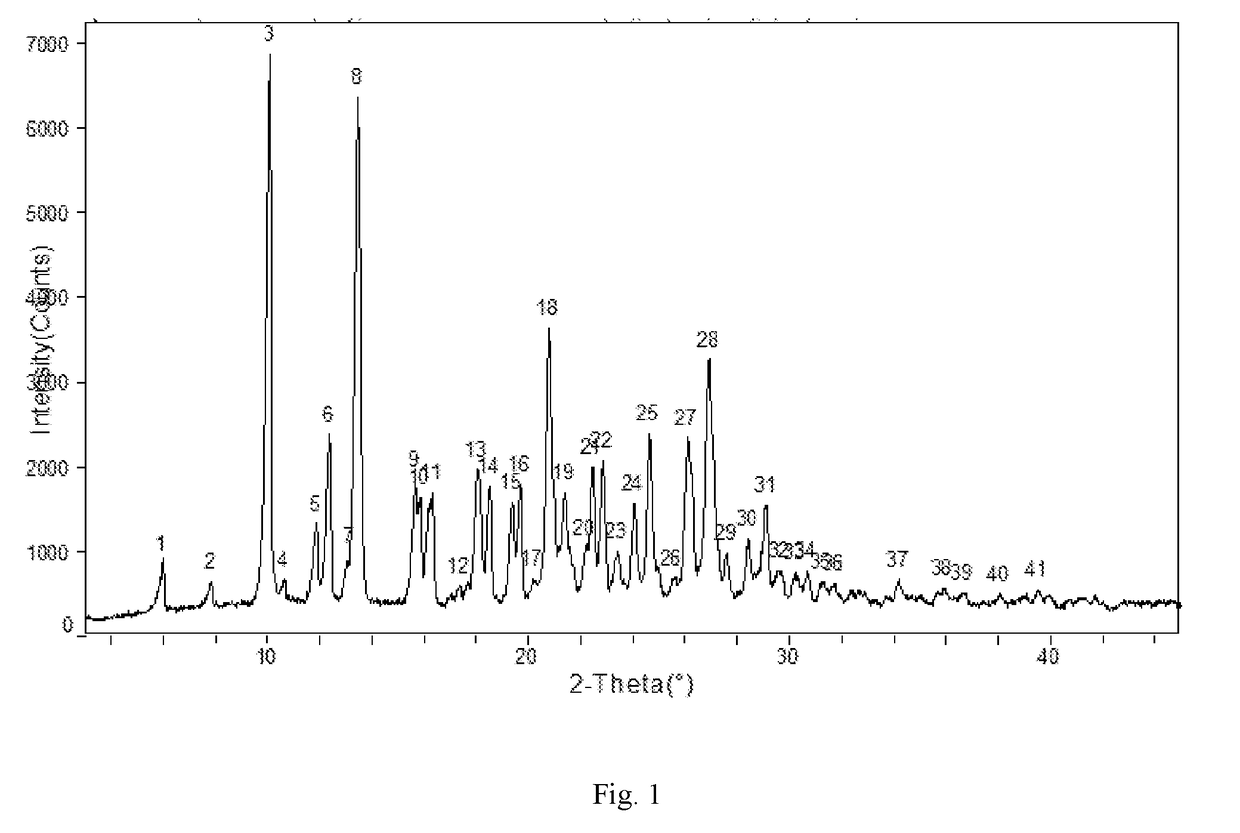

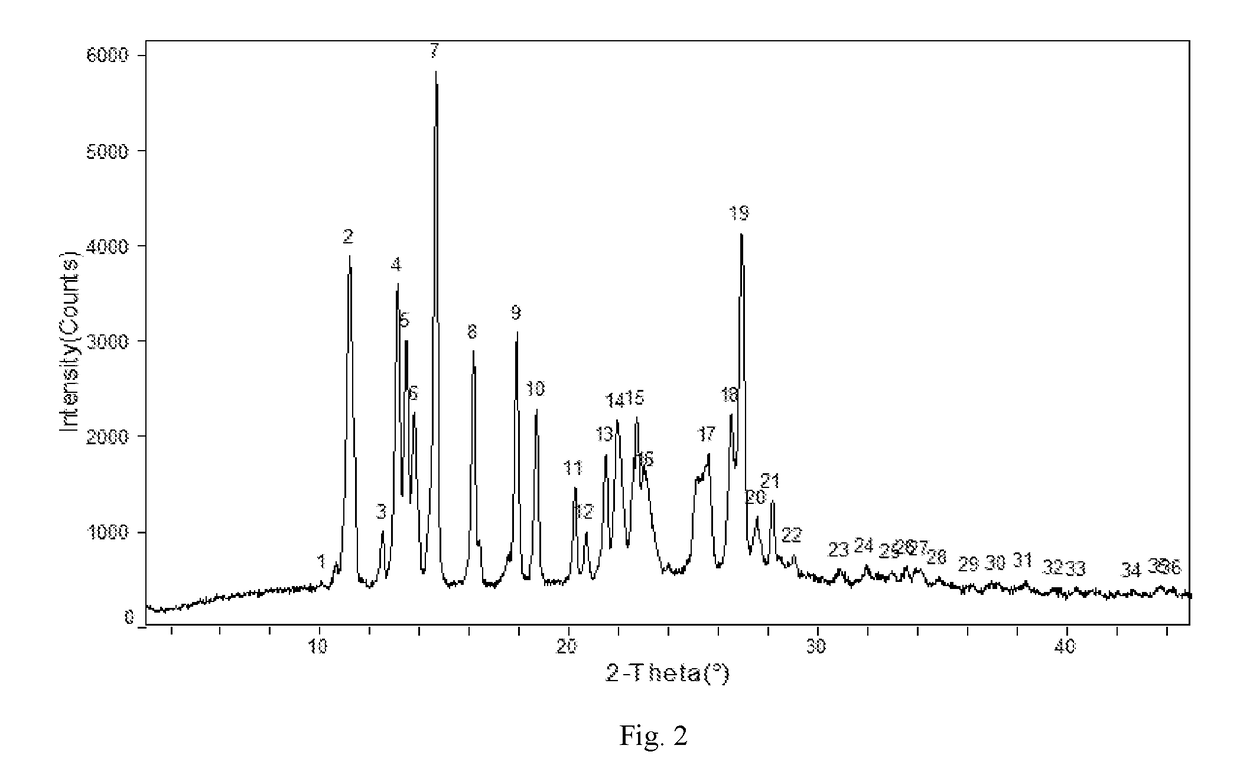

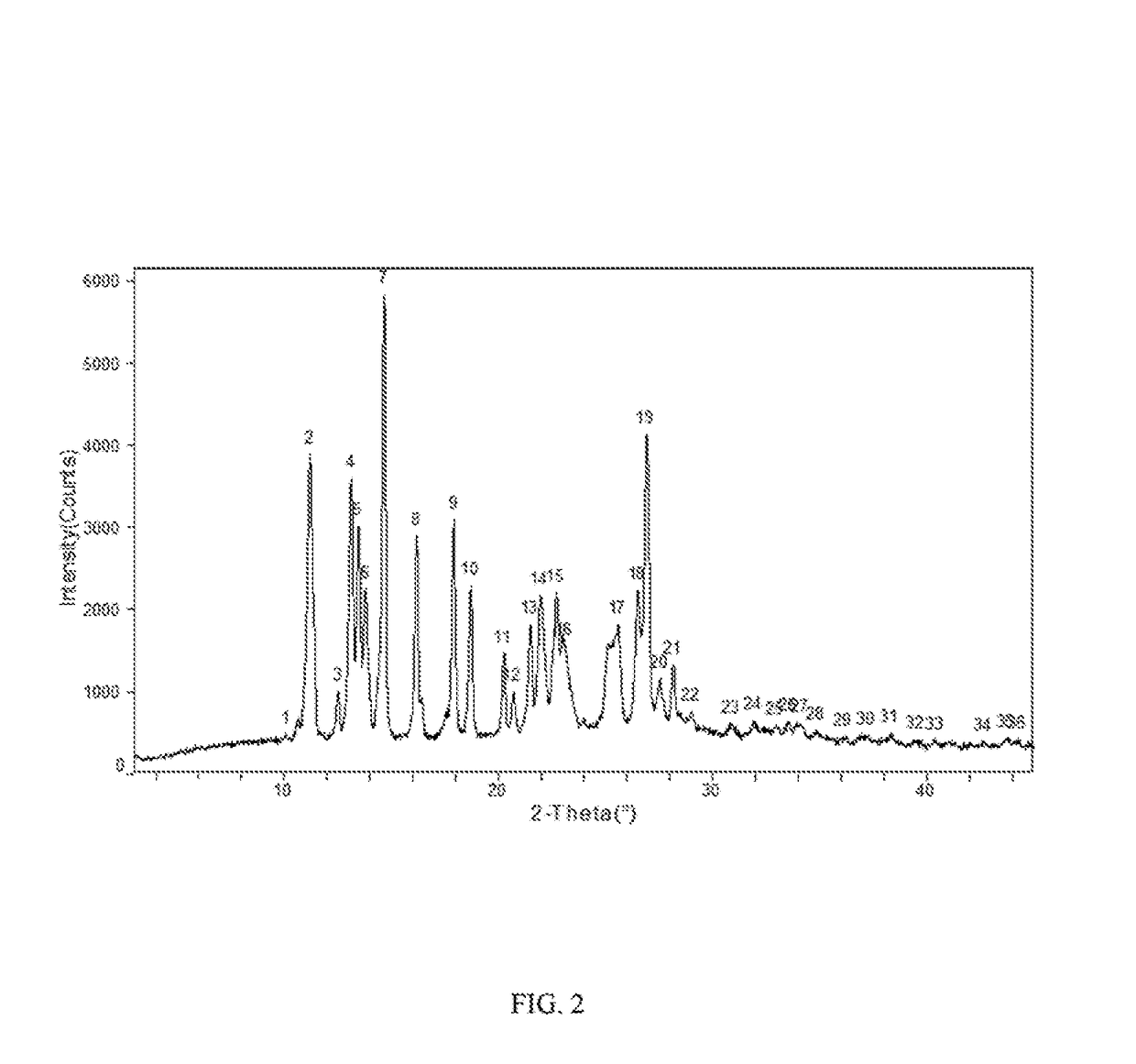

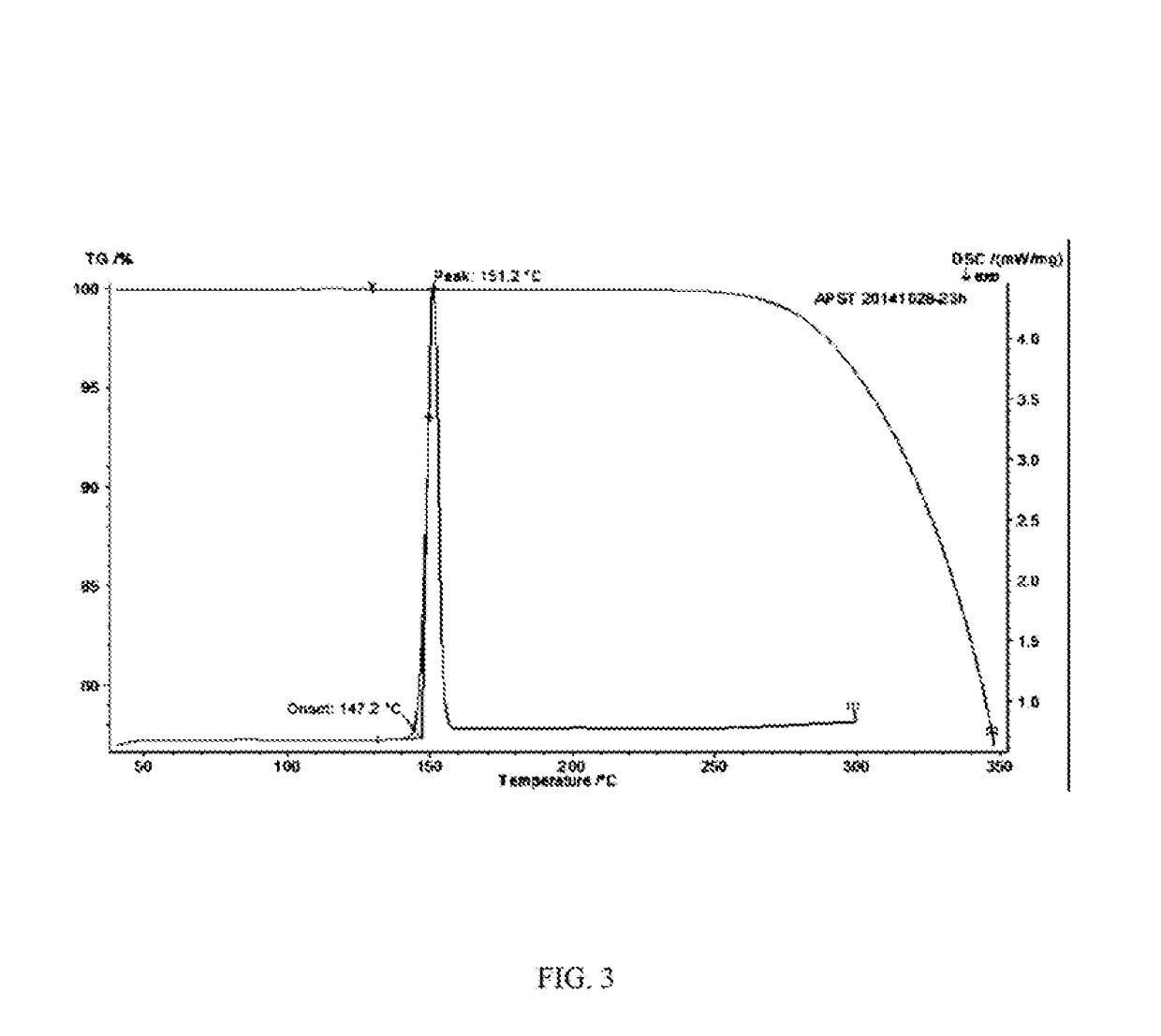

Stable apremilast crystalline form ii free of solvate and method of making the same

ActiveUS20170298018A1Easy to prepareIncreased formationSenses disorderNervous disorderPhysical chemistryPharmaceutical drug

A stable Crystalline Form II of non-solvate of Apremilast (Formula I), methods of making Form II, pharmaceutical compositions comprising Form II, and their uses are disclosed. Also discloses are mixed crystals comprising Form Hand Form B and methods of making the same. The crystalline forms are characterized using X-ray powder diffractometry (XRPD), infrared spectroscopy (IR), differential scanning calorimetry (DSC), and thermal gravimetric analysis (TG). As compared with Forms A, B, C, D, E, F, and G reported in prior art references, Apremilast Form II of the present invention is more stable to temperature, light, and humidity, and is more suitable for long term storage; the crystallization solvents are safe and can be easily removed; the Form II has a white or off white appearance, and can be directly used in preparation processing; the preparation methods are simple and easy to reproduce, and are suitable for industrialized production.

Owner:UTOPHARM SHANGHAI +1

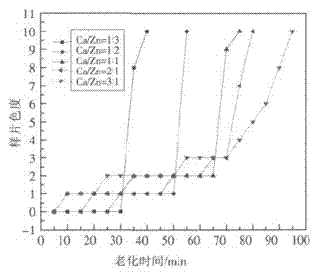

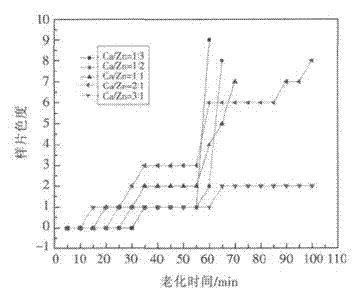

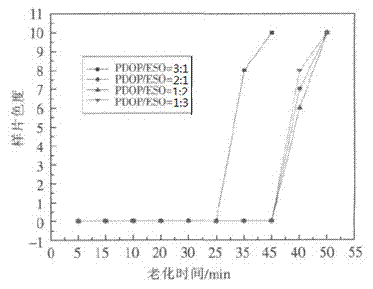

Method for preparing PVC (Polyvinyl Chloride) heat stabilizing agent by using liquid-state Ca/Zn

The invention provides a method for preparing a PVC (Polyvinyl Chloride) heat stabilizing agent by using liquid-state Ca / Zn. The invention researches the influences on the heat stability of the PVC, caused by a mass ratio of calcium to zinc, a mass ratio of a phosphorous acid-phenyl diisooctyl phthalate to epoxy soybean oil (ESO) and hydrotalcite (LDHs), in a liquid calcium-zinc (liquid Ca / Zn) heat stabilizing agent through an overheating ageing oven method, a dynamic heat stability test and a Congo red method; and meanwhile, an ultraviolet and visible spectrophotometer and a thermo-gravimetric analyzer are used for detecting the influences of the LDHs to the transparency and the stability of the PVC.

Owner:苏州宝津塑业有限公司

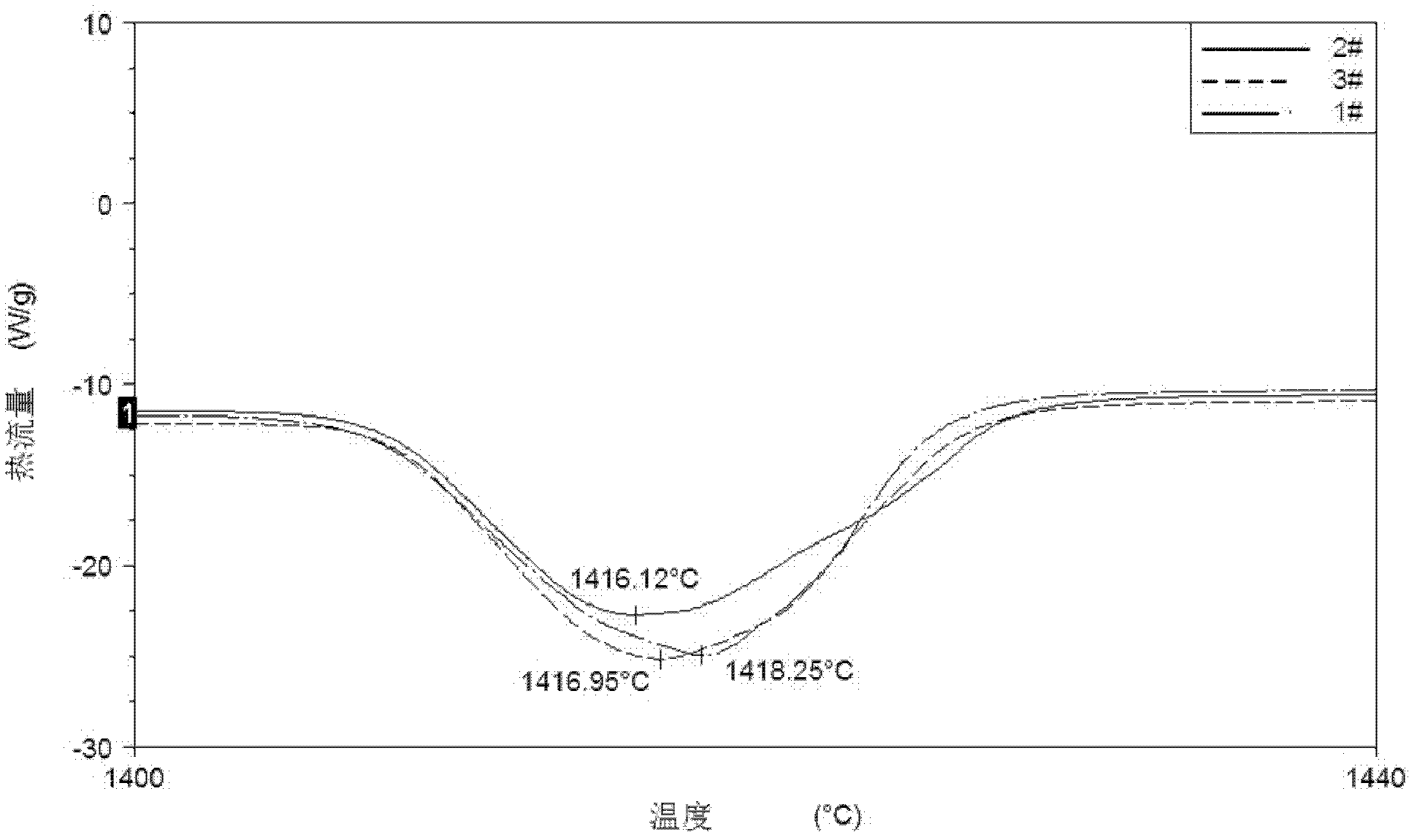

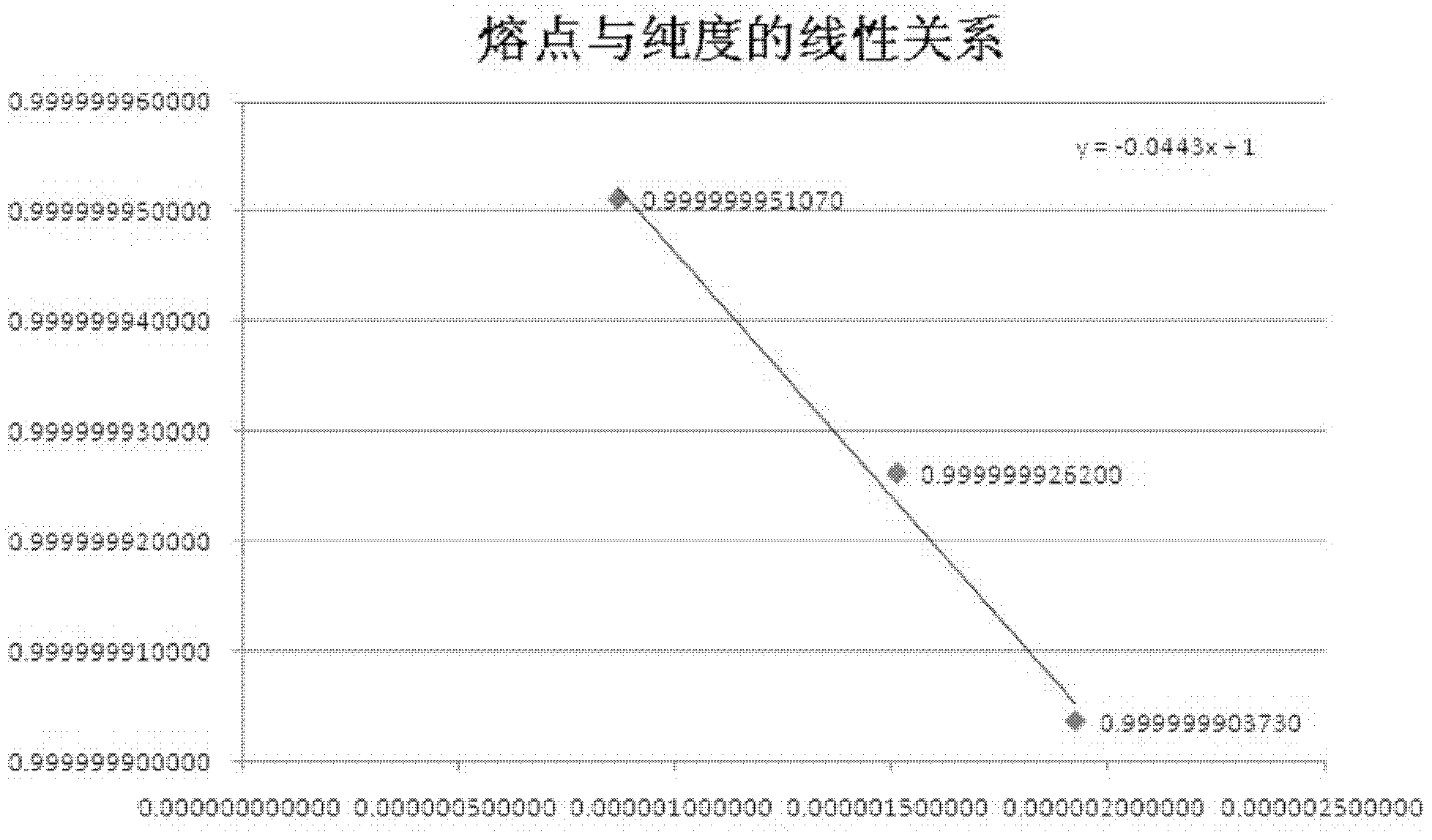

Method for judging purity of silicon for crystalline silicon solar battery

InactiveCN102608147ALow costImprove quality controlInvestigating phase/state changeQuality controlLinear relationship

The invention relates to a method for judging purity of silicon for a crystalline silicon solar battery, which comprises the steps of: a, weighing silicon samples with given weight, b, adopting gas shield at a certain flow (80-120mL / min) and allowing the silicon samples to be fused at a certain heating rate (3-100 DEG C / min) and in a certain temperature range (0-1500 DEG C) in a simultaneous differential scanning calorimeter-thermo gravimetric analyzer (SDT), c, regressing a linear relationship between purities and melting points according to at least three samples with known purities and correct melting point testing results of the samples based on testing conditions set in Steps a and b, and d, calculating the purity of unknown samples according to the linear relationship between the purities and the melting points for other samples with unknown purities as long as the melting points of the samples with unknown purities are measured. The method has the beneficial effects that: 1, the operation is automatic, the total cost is lower, and the quality control is facilitated, 2, the method is a physical method for directly measuring the changes in the melting points, and is scientific and reasonable, and 3, the measuring precision is high, and the stability is higher.

Owner:TRINA SOLAR CO LTD

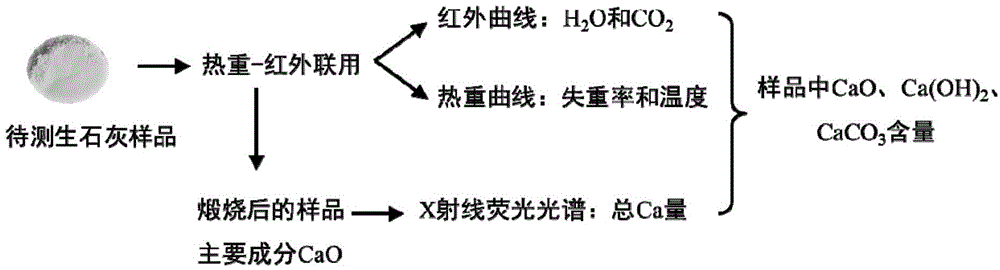

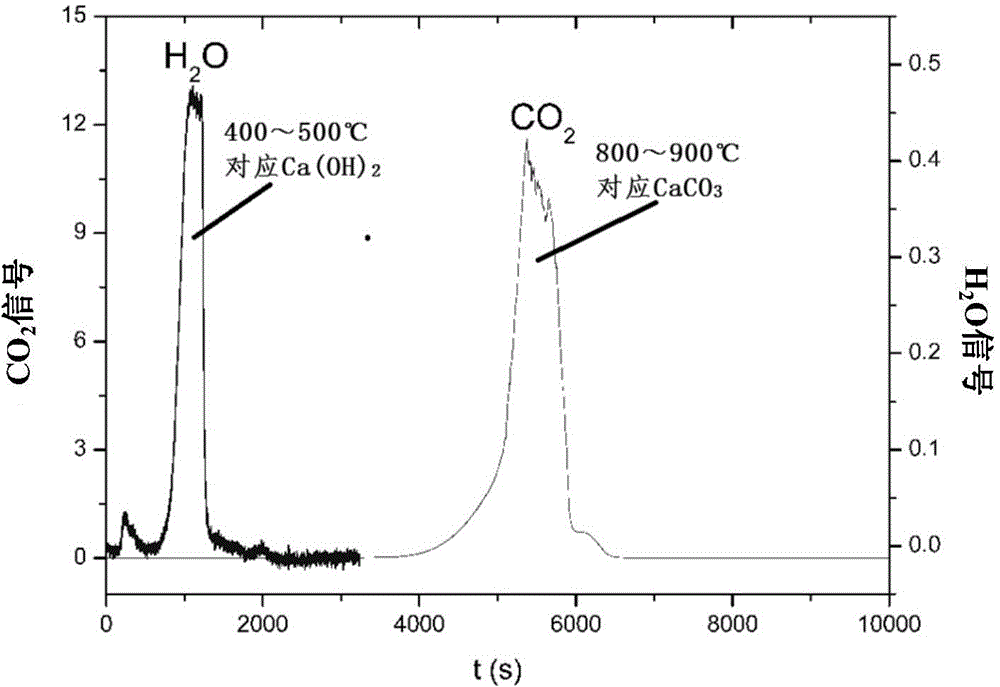

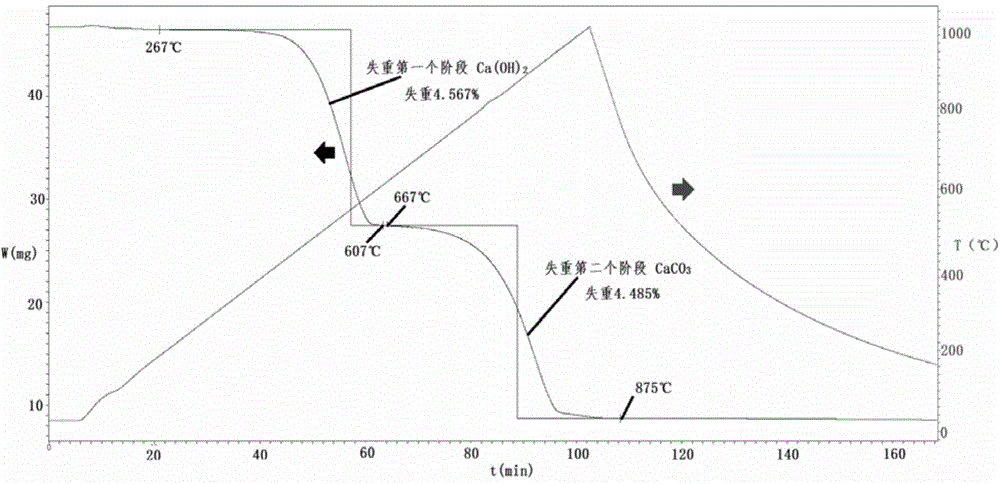

Desulfurized quicklime effective ingredient determination method

ActiveCN104897511AContent effective distinctionReduce mistakesWeighing by removing componentMaterial analysis using wave/particle radiationElement analysisBiology

The present invention provides a desulfurized quicklime effective ingredient determination method, and the method is as follows: analysis and determination of kind and content of decomposable effective ingredients in a desulfurized quicklime sample, and element analysis of the undecomposed sample to determine the content of effective ingredients in the undecomposed sample so as to determine the content of effective ingredients in the desulfurized quicklime sample. By use of thermo-gravimetric and infrared spectroscopy coupled technology combining X-ray fluorescence spectrum, the content of the effective ingredients in the desulfurized quicklime can be determined, the method greatly reduces the artificial operation error, and can effectively distinguish the content of CaO, Ca (OH) 2 and CaCO3 in the desulfurized quicklime sample, and the results are accurate and reliable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Stable apremilast crystalline form II free of solvate and method of making the same

ActiveUS9850205B2Increased formationPromote formationSenses disorderNervous disorderPhysical chemistryPharmaceutical drug

A stable Crystalline Form II of non-solvate of Apremilast (Formula I), methods of making Form II, pharmaceutical compositions comprising Form II, and their uses are disclosed. Also discloses are mixed crystals comprising Form Hand Form B and methods of making the same. The crystalline forms are characterized using X-ray powder diffractometry (XRPD), infrared spectroscopy (IR), differential scanning calorimetry (DSC), and thermal gravimetric analysis (TG). As compared with Forms A, B, C, D, E, F, and G reported in prior art references, Apremilast Form II of the present invention is more stable to temperature, light, and humidity, and is more suitable for long term storage; the crystallization solvents are safe and can be easily removed; the Form II has a white or off white appearance, and can be directly used in preparation processing; the preparation methods are simple and easy to reproduce, and are suitable for industrialized production.

Owner:UTOPHARM SHANGHAI +1

Method for preparing benzene end-capping polyaryletherketone polyme

ActiveCN102702459BMeet the requirements of continuous productionOrganic compound preparationCarbonyl compound preparation by condensationChemical reactionPhenyl Ethers

The invention relates to a method for preparing benzene end-capping polyaryletherketone polymers, which belongs to the technical field of high polymer materials. The preparation method comprises the steps as follows: using 4-(p fluorophenyl acyl) biphenyl or 4-(p fluorophenyl acyl) phenyl ether as an end-capping agent, using 4,4'-difluorobenzophenone and a bisphenol monomer as reactants, and using a nucleophilic route to prepare the benzene end-capping polyaryletherketone polymers with glass transition temperature of 147 DEG C and initial thermo-gravimetric temperature above 540 DEG C. Two detailed chemical equations describing the preparation process are attached. With two end-capping monomers having boiling points above 320 DEG C and suitable process conditions, the method for preparing the benzene end-capping polyaryletherketone polymers solves the technical problem caused by the fact that the p fluorophenyl acyl has low boiling point and volatilizes in an end-capping reaction in the prior art, and synthetizes polyaryletherketone with a benzene oxygen end group and polyaryletherketone with a biphenyl end group, so as to meet the requirement of continuous industrial production.

Owner:山东君昊高性能聚合物有限公司

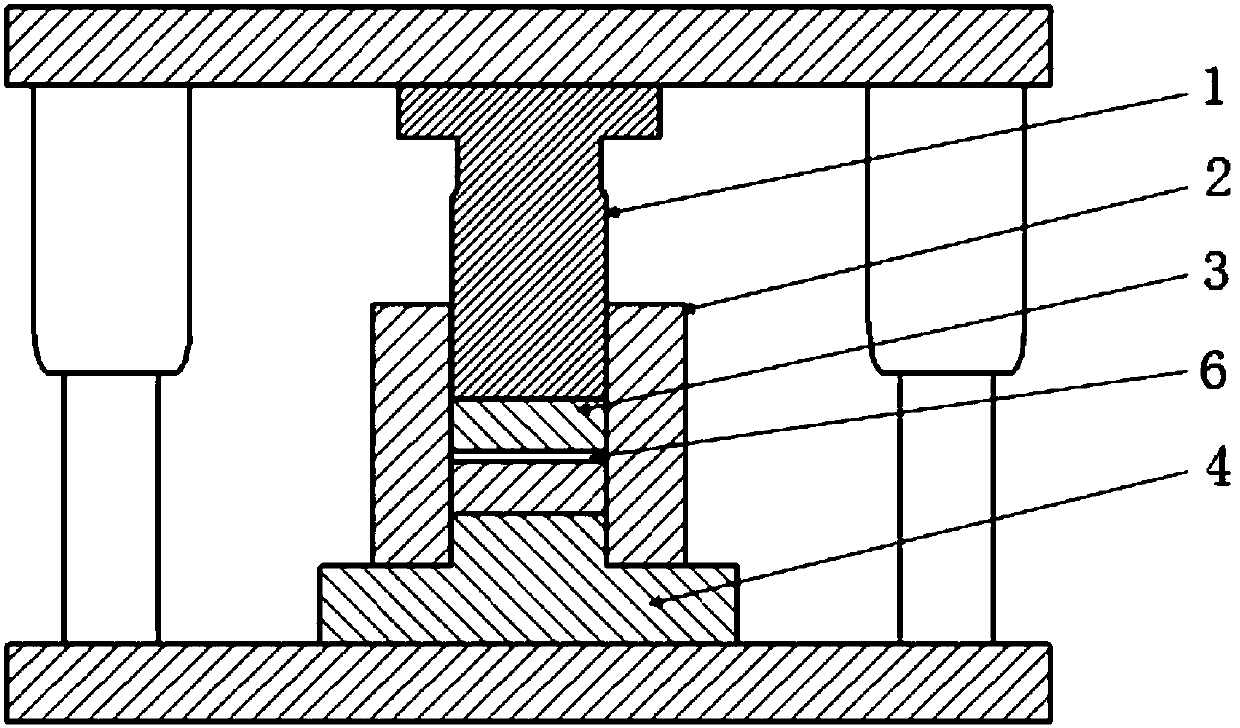

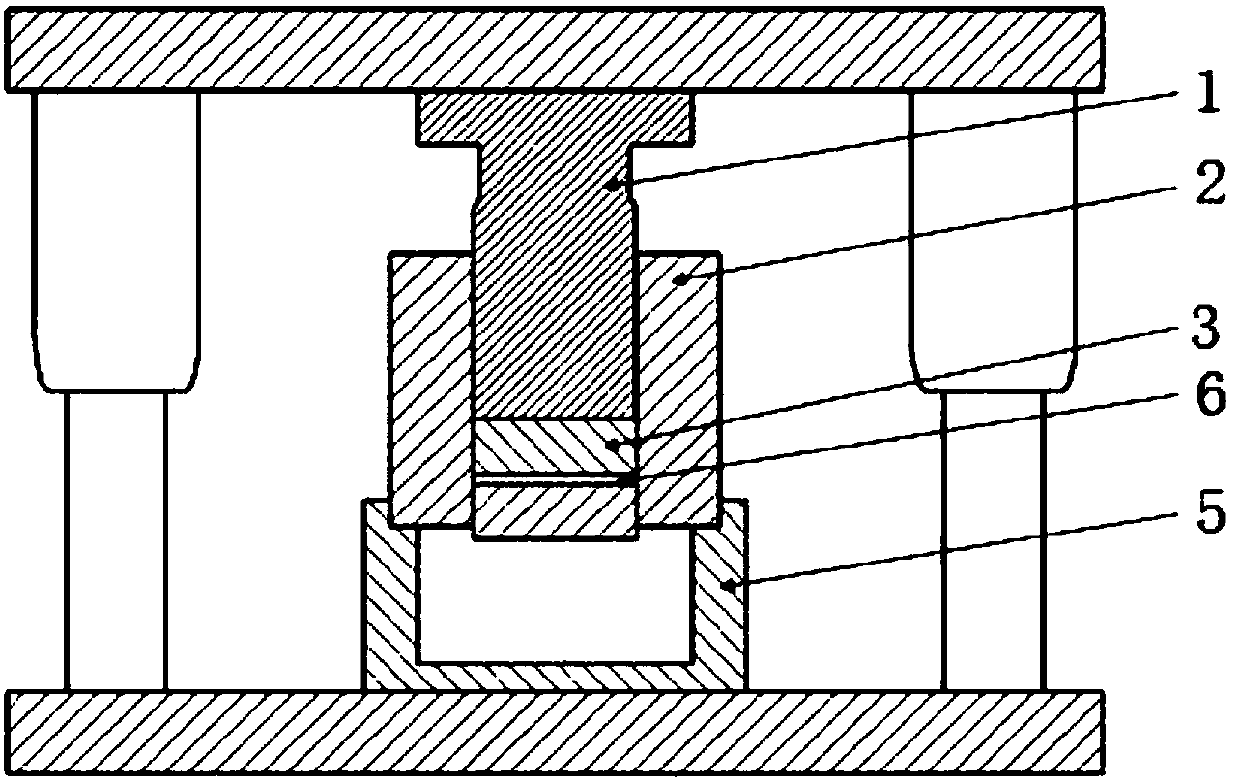

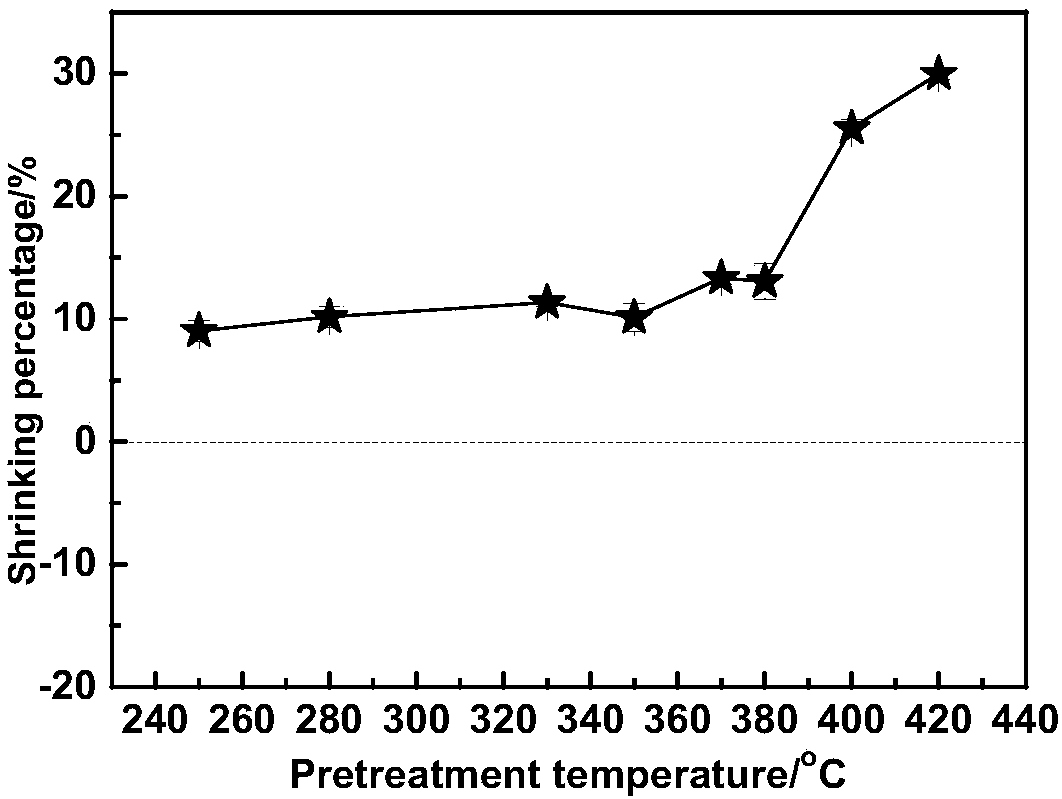

Forming method for manufacturing high-quality transparent piece based on photonic crystal high-elastic state method

ActiveCN107696372AMaintain mesoscopic structural morphologyAvoid orientation problemsDecompositionPhotonics

The invention belongs to the technical field of plastic machining forming and discloses a forming method for manufacturing a high-quality transparent piece based on a photonic crystal high-elastic state method. The forming method comprises the following steps that (1) materials are prepared; (2) machining conditions are obtained, specifically, the decomposition temperature of photonic crystals isobtained through thermogravimetry, and the glass-transition temperature and the viscous flow transition temperature of the materials are obtained through differential scanning calorimetry; (3) a mouldis prepared; (4) the materials are added in the mould; (5) heating is conducted, specifically, the photonic crystals are heated to enter into a high-elastic state, and heat preservation is conductedto guarantee that the photonic crystals are completely transformed into the high-elastic state; and (6) pressure maintaining and cooling are conducted, specifically, the pressure is increased to enable the photonic crystals to be combined mutually, then heating is stopped, the pressure is maintained, the photonic crystals are cooled with the mould to the indoor temperature, and accordingly the transparent piece is obtained. The macro orientation problem of the product due to the fact that molecular chains are distributed regularly because of shear flow and shrinkage of the materials is avoided, the product is in a uniform and regular periodic structure microcosmically, and the forming quality is good.

Owner:HUAZHONG UNIV OF SCI & TECH

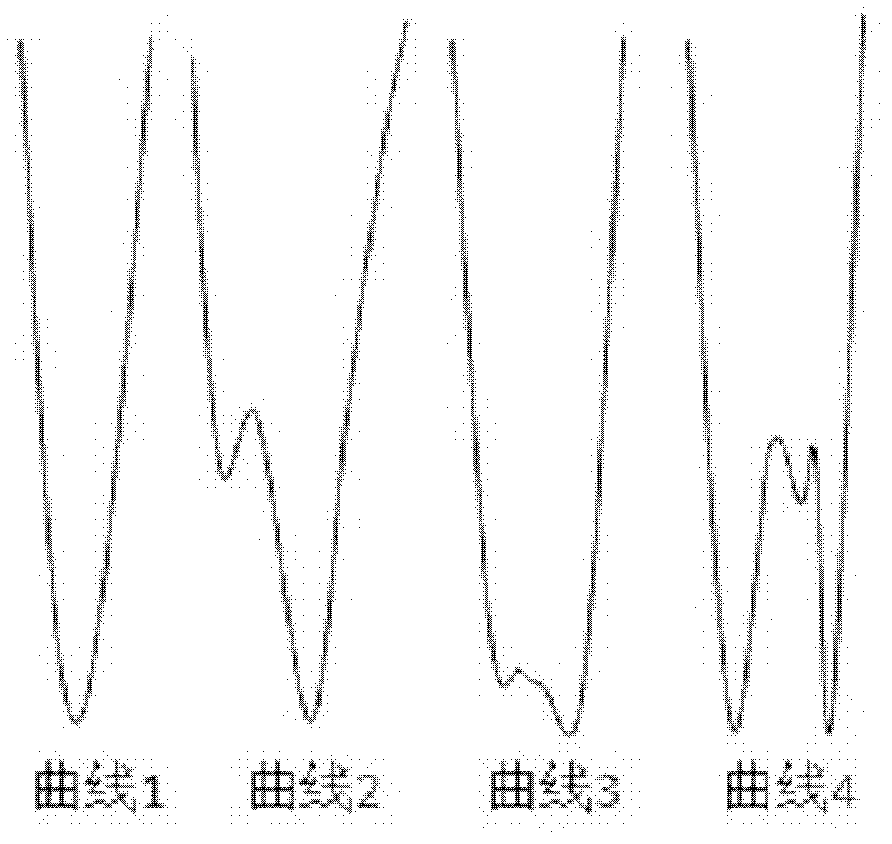

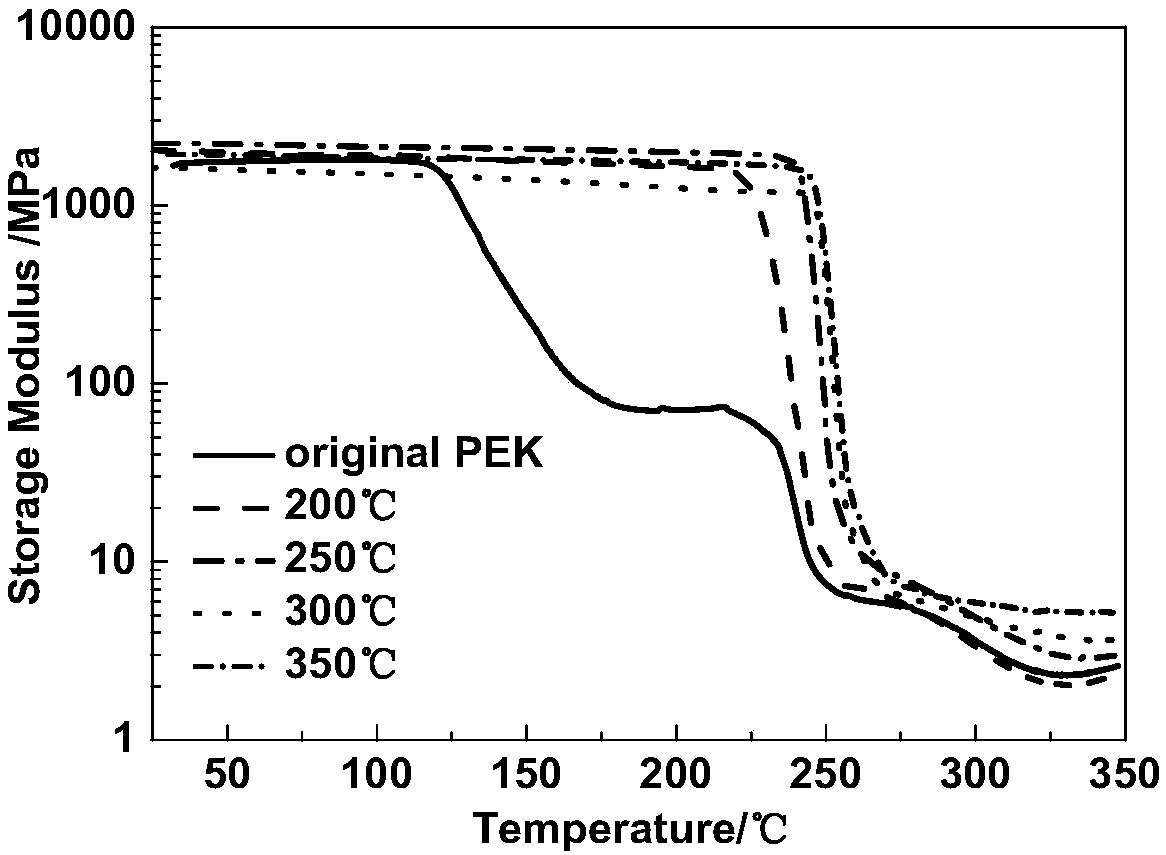

Method for judging thermo-crosslinking process scope of thermoplastic polymer

ActiveCN108034059AJudging the degree of thermal crosslinkingIntuitive degree of thermal crosslinkingCross-linkCarbon film

The invention relates to a method for judging the thermo-crosslinking process scope of a thermoplastic polymer, belonging to the field of new technology development. According to the method for judging the thermo-crosslinking process scope of the thermoplastic polymer, a thermo-gravimetric curve of the thermoplastic polymer or a weight variation curve of the thermoplastic polymer treated by meansof different thermo-crosslinking processes as well as an energy storage modulus curve or a loss factor curve related to dynamic thermal mechanical analysis of a thermo-crosslinking film are comprehensively analyzed, and the cross-linking process conditions of the optimum thermal cross-linking degree upper limit and the cross-linking process conditions of the optimal thermal cross-linking degree lower limit are judged, so that the optimal thermal cross-linking degree is determined. The method for judging the thermo-crosslinking process scope of the thermoplastic polymer can be used for simply,conveniently and visually judging the thermal cross-linking degree of the thermoplastic polymer, thus not only being capable of effectively regulating and optimizing the structure and performance of athermoplastic polymer-based carbon film, but also being applied to other fields, such as preparation of high toughness and high damage tolerance resin composite material matrix, of application of thecrosslinked thermoplastic polymer.

Owner:DALIAN UNIV OF TECH

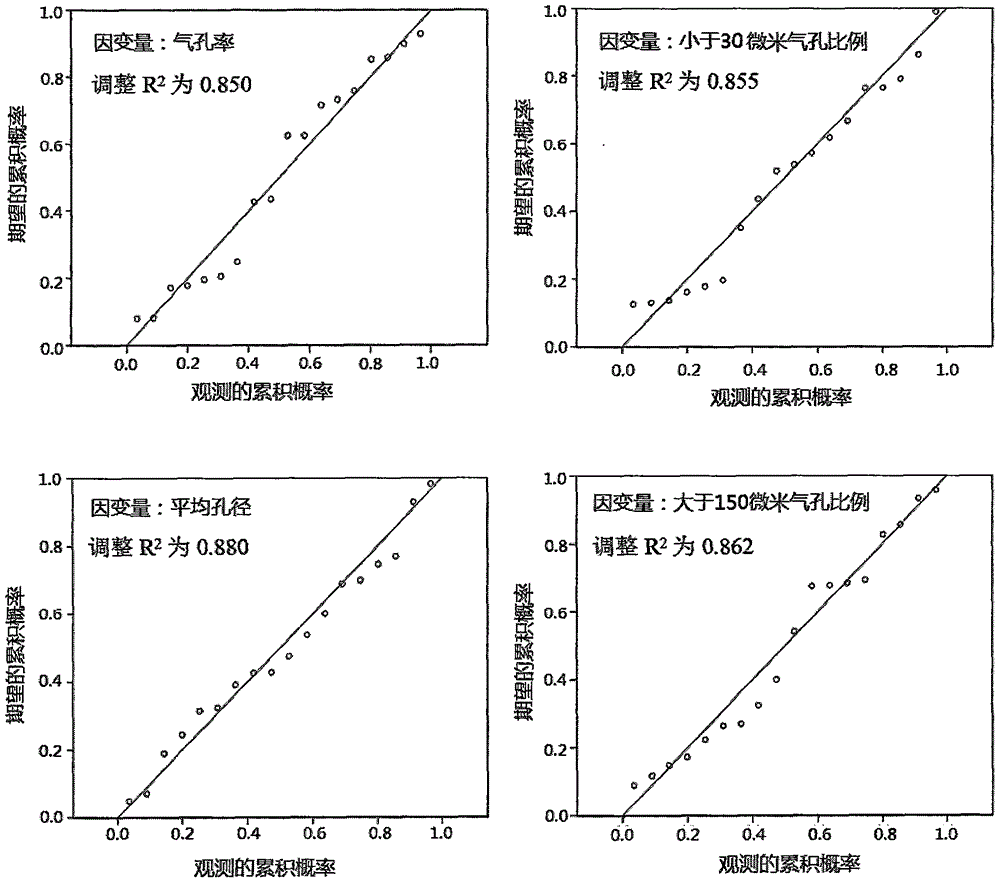

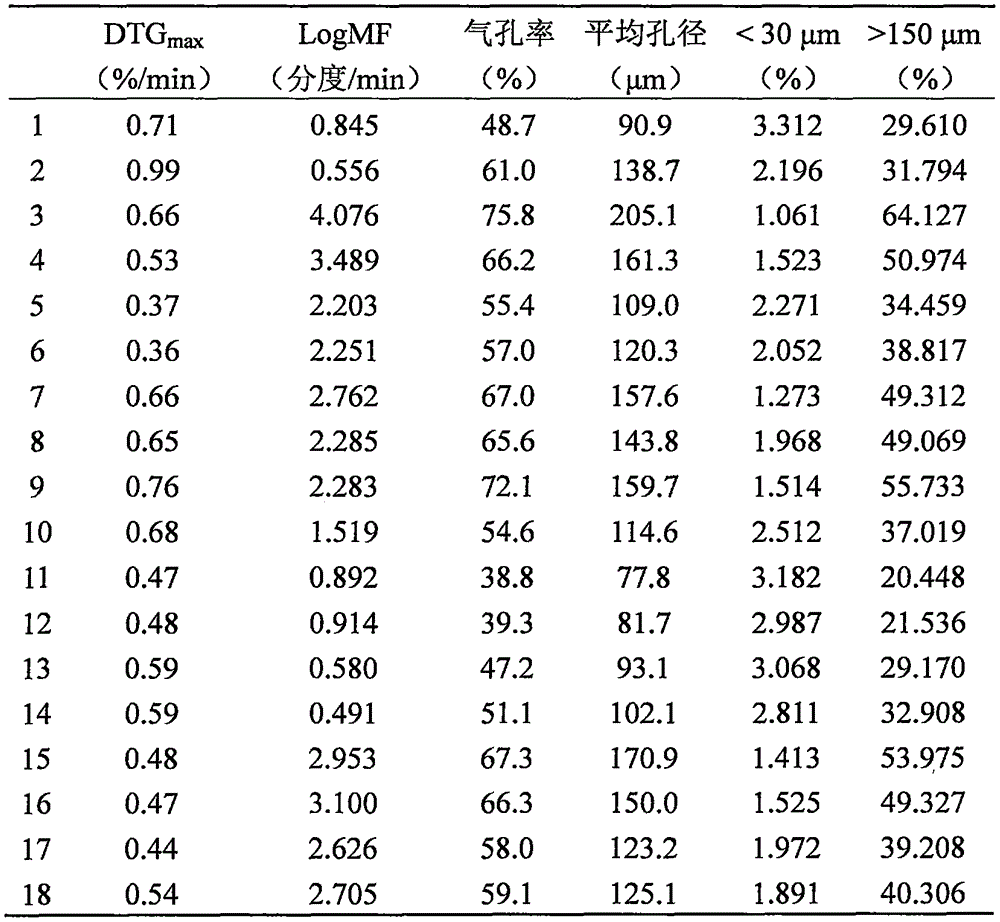

Method for establishing metallurgical coke pore feature parameter prediction model

ActiveCN106547935AEasy to testImprove accuracySpecial data processing applicationsImaging analysisPredictive methods

The invention discloses a method for establishing a metallurgical coke pore feature parameter prediction model. The method is characterized by comprising the steps of: 1) performing thermo-gravimetric analysis test on a single coal of more than 15 different coal ranks and a matching coal thereof to obtain a maximum volatile de-volatilization rate DTGmax (% / min) of each sample; 2) performing Gieseler fluidity test on a coking coal to obtain a maximum Gieseler fluidity MF (graduation / min) of each sample; 3) performing coking test on the coking coal samples, and obtaining the average pore size, porosity, proportion of pores smaller than 30 microns and proportion of pores greater than 150 microns of coke via an image analysis method; and 4) performing binary linear regression on the average pore size, porosity, proportion of pores smaller than 30 microns and proportion of pores greater than 150 microns of the coke respectively by using DTGmax and LgMF as independent variables to obtain a relation between the pore structure parameters and the DTGmax and LgMF. The prediction method is simple and convenient in test and high in prediction accuracy.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

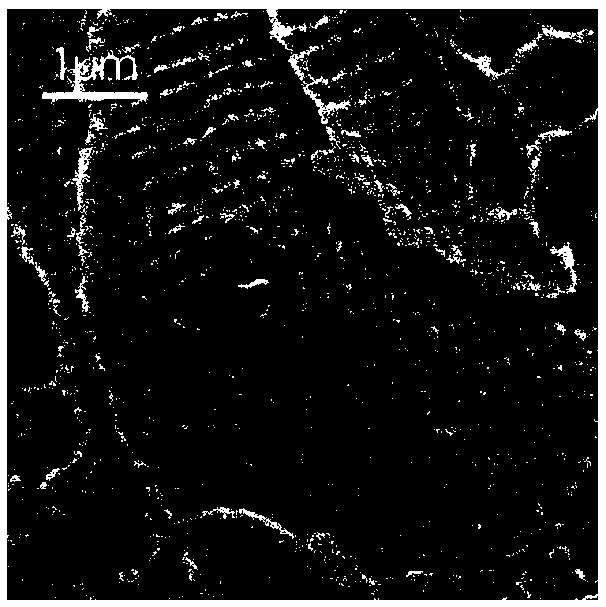

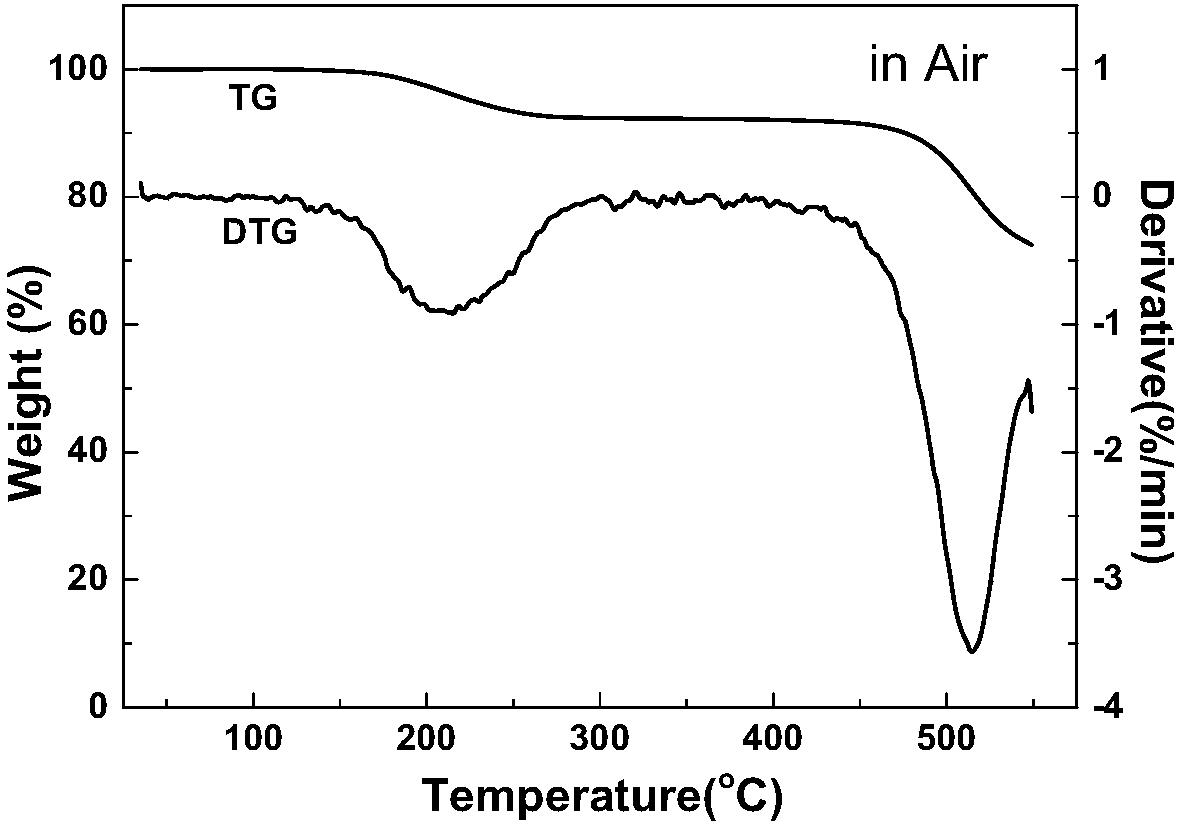

Combustion dynamic parameter-based asphalt component thermal stability evaluation method

InactiveCN109060878AMaterial analysis using wave/particle radiationChemical analysis using combustionElement analysisBituminous materials

The invention relates to a novel method for evaluating asphalt four-component combustion dynamics based on a plurality of heating rates, belongs to the technical field of asphalt materials, and solvesthe problems that the temperature rise rate variability is difficult to simulate in actual fire disaster on the basis of a single heating rate, the reliability in calculation of the combustion dynamics parameters is poor, the thermal stability of all the components of the asphalt is difficult to objectively evaluate, and the asphalt combustion dynamics characteristic cannot be deeply evaluated. The method comprises the following steps of firstly, separating four components from asphalt, and carrying out industrial and element analysis respectively; carrying out thermo-gravimetric analysis inthe air, raising the temperature to 800 DEG C from the room temperature at three temperature rising rates, and obtaining a TG-DTG curve; dividing different combustion stages, and calculating dynamic parameters of different combustion stages by adopting a differential method and an integral method, and carrying out mutual checking; and finally, observing the microscopic morphology of the surface ofthe combustion residue, testing element components and contents, comparing the dynamic parameters of different combustion stages of the asphalt components, evaluating the four-component thermal stability of the asphalt, and disclosing the asphalt combustion characteristic from the component level.

Owner:NANJING FORESTRY UNIV

A wo3/v2o5/fto composite photoelectrode and its preparation and use method

ActiveCN105923694BReduce manual laborIncrease spinning speedWater/sewage treatment by irradiationInorganic material artificial filamentsFiberTungstate

The invention belongs to the field of materials and discloses a method for preparing a conductive glass (FTO)-loaded tungsten trioxide (WO3) / vanadium pentoxide (V2O5) composite photoelectrode (WO3 / V2O5 / FTO). The method comprises the following steps: adopting vanadyl acetylacetonate and ammonium tungstate as raw materials, polyvinylpyrrolidone (PVP) as an auxiliary material, and dimethylformamide (DMF) and oxalic acid solution as solvents; loading a composite precursor onto conductive glass according to an electrostatic spinning technology and finally carrying out high-temperature roasting to obtain a WO3 / V2O5 / FTO composite photoelectrode material with high photo-electro-catalytic activity. The material is characterized through scanning electron microscope (SEM), X-ray diffraction (XRD), thermo-gravimetric-differential thermal analysis (TG-DTA), X-ray photoelectron spectroscopy (XPS), Fourier transform infrared ray spectroscopy (FT-IR) and other means, so that the fiber material obtained by the method disclosed by the invention can be discovered that the release is uniform, and the diameter is 100-150 nm. The WO3 / V2O5 / FTO composite photoelectrode material prepared by adopting the method disclosed by the invention is simple in process and has higher photocatalysis under visible light.

Owner:JISHOU UNIVERSITY

Microwave Materials Science Workstation

The invention discloses a microwave material science workstation, which belongs to the technical field of the microwave heating. The microwave material science workstation mainly consists of a sealed microwave metal cavity, a functional interface, a function modularization heating cavity, a microwave generation and control system, a temperature control system and a cooling system. The microwave material science workstation adopts three heating modes, namely pure microwave heating, traditional electric heating and mixed heating and contains or develops various functions by the functional interface, i.e. functions of a muffle furnace, a tube furnace, a chemical reactor, a microwave digestion instrument, an in-situ thermo gravimetric analyzer, a kinetic analysis instrument, a microwave electric arc furnace, a multiple temperature zone heating furnace, a high-temperature compression furnace and a stretching furnace, wherein all functional modules are movably connected and movably assembled, and different functional modules are freely changed. The microwave material science workstation with the above characteristics has the advantages of strong function, low cost, remarkable energy saving property, small land occupation and great popularization and application value as well as commercial value, is equivalent to tens of experiment instruments and can be used as a movable material science experiment platform.

Owner:唐山纳源微波热工仪器制造有限公司

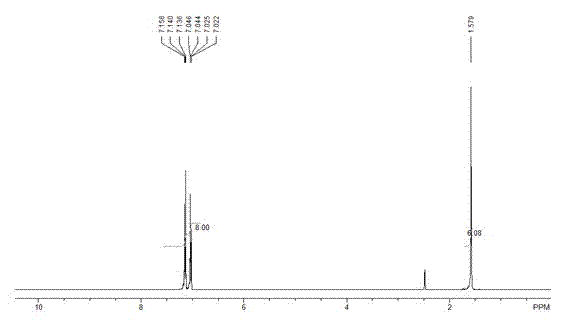

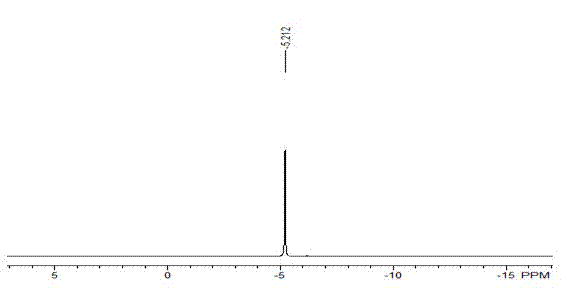

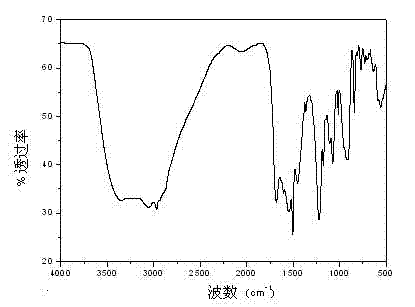

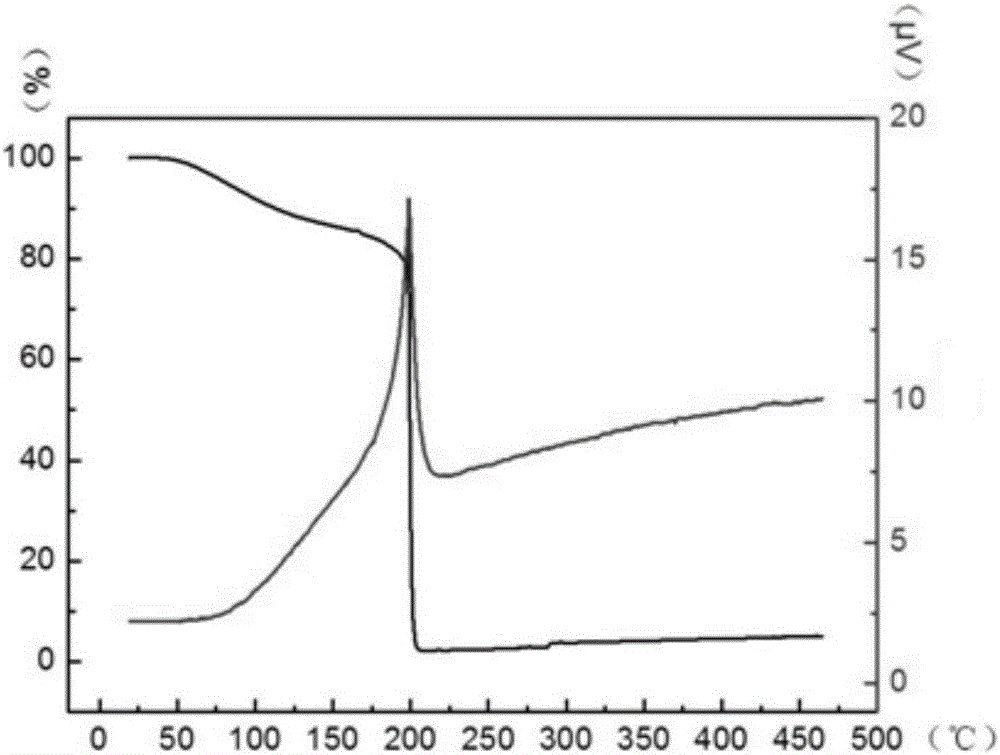

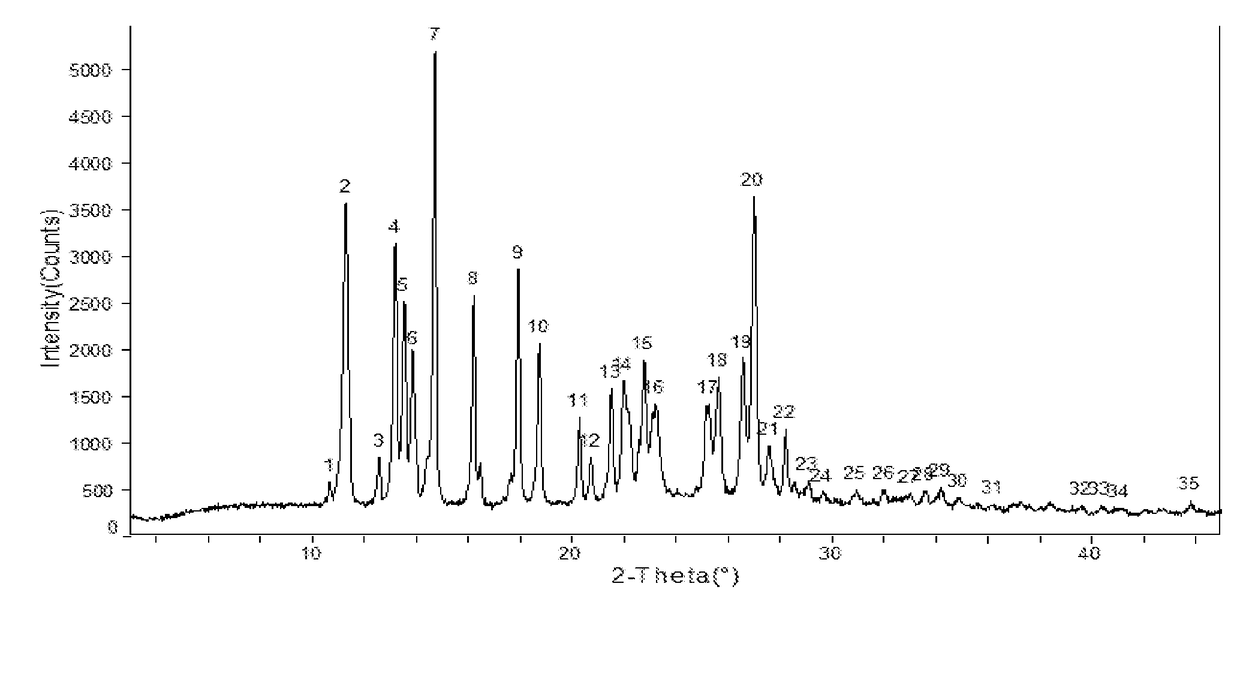

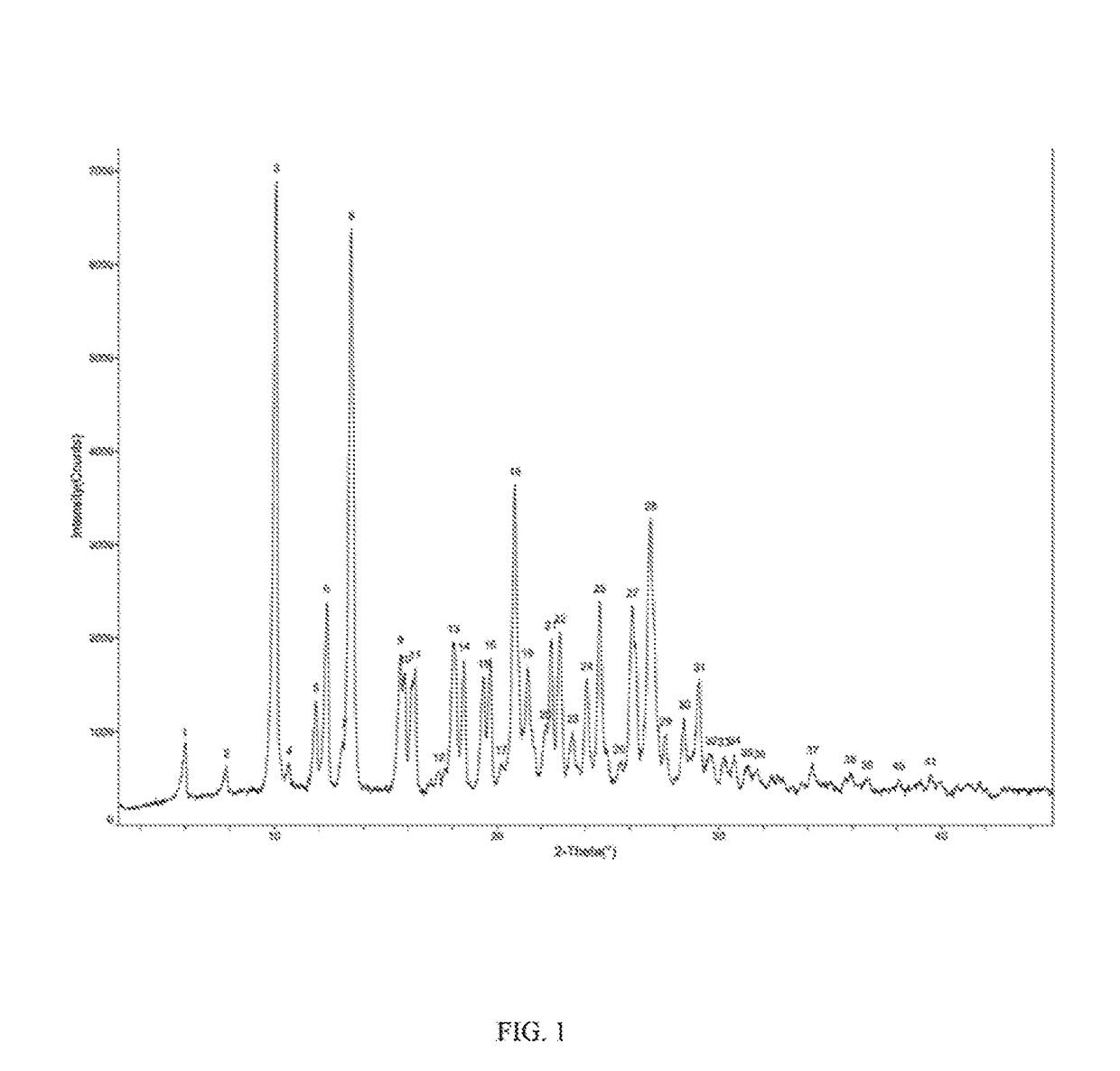

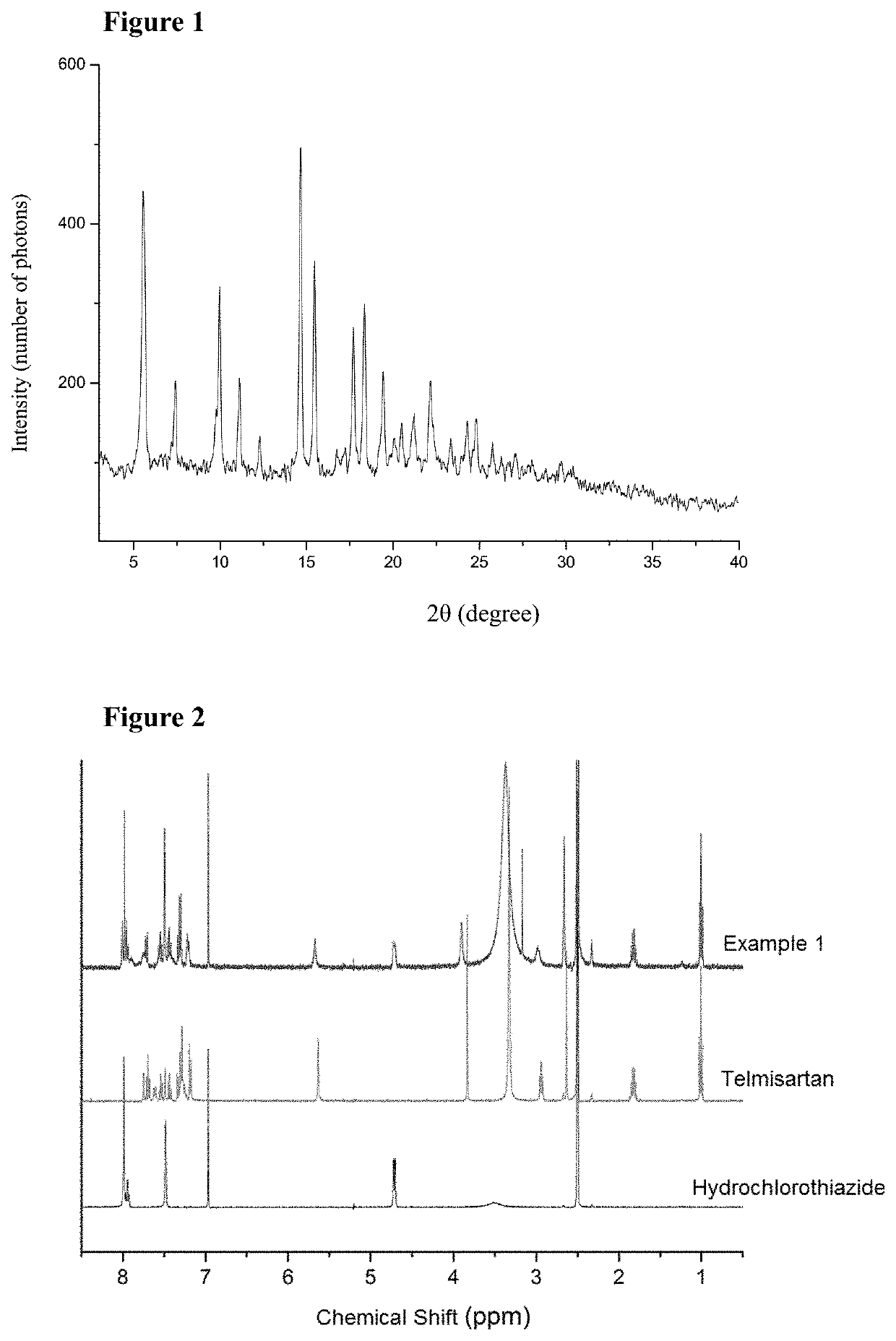

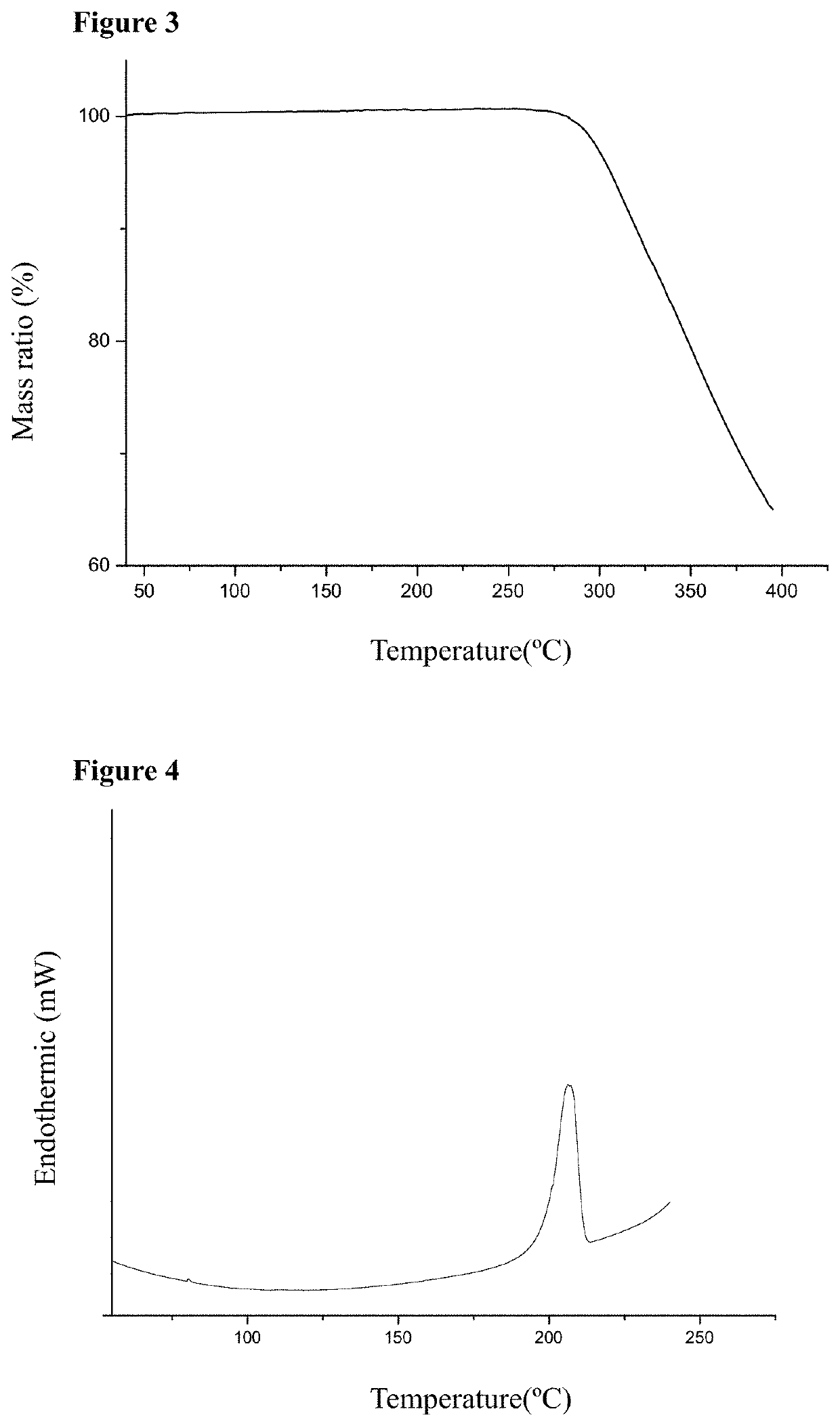

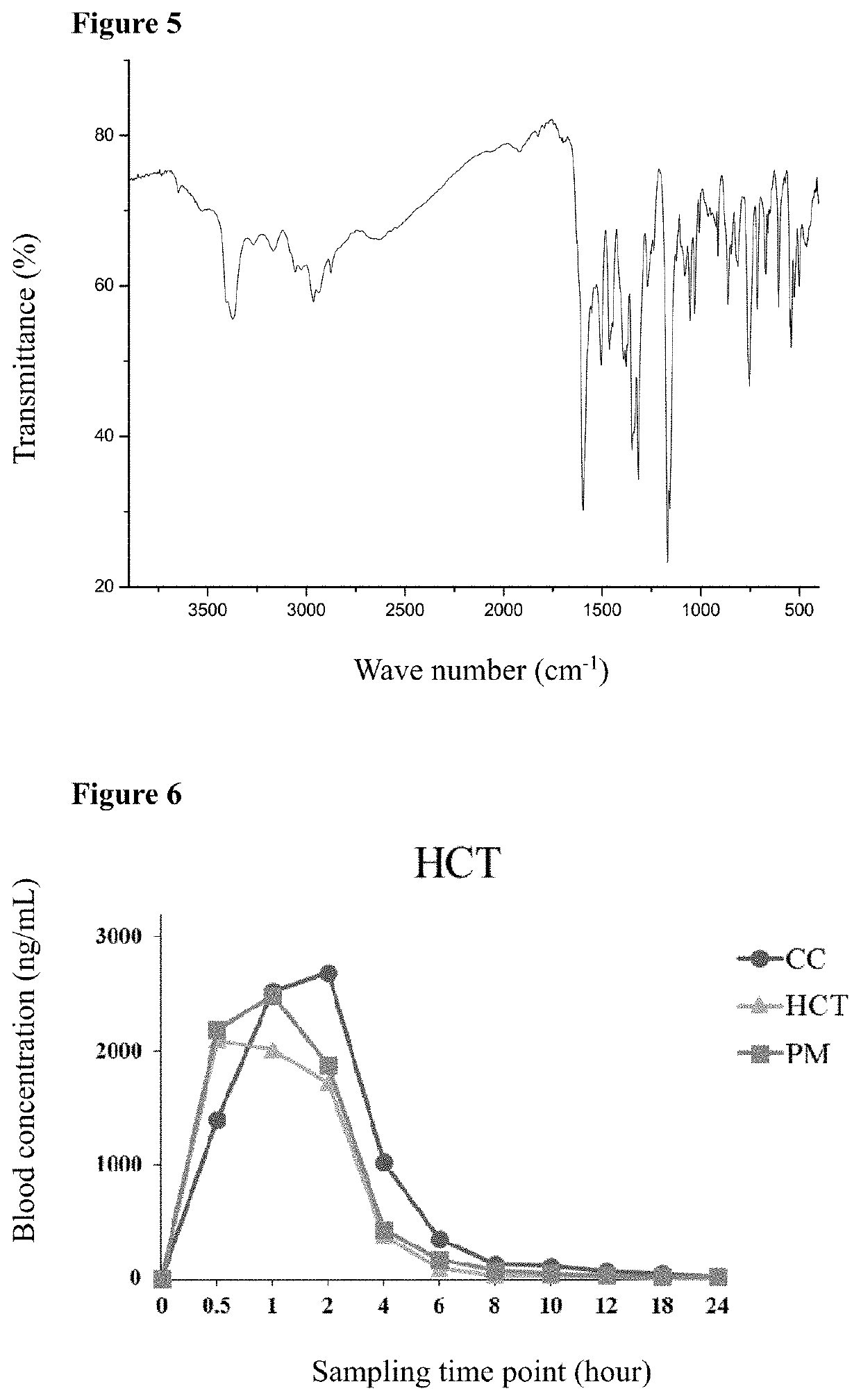

Cocrystal of Telmisartan and Hydrochlorothiazide

InactiveUS20200181121A1Easy to controlIncrease contentOrganic active ingredientsOrganic chemistry methodsFt ir spectraBlood plasma

The present disclosure relates to a cocrystal of telmisartan and hydrochlorothiazide, a preparation method and use thereof. In the cocrystal, the molar ratio of telmisartan and hydrochlorothiazide is 1:1. The cocrystal of telmisartan and hydrochlorothiazide was characterized by X-ray powder diffraction (XRPD), proton nuclear magnetic resonance spectra (1H-NMR), thermal gravimetric analysis (TG), scanning differential calorimetry (DSC) and infrared (IR) spectra, and it was found that the maximum plasma concentration of the cocrystal in SD rats was higher than that of any one of hydrochlorothiazide and telmisartan itself. The cocrystal of telmisartan and hydrochlorothiazide has a simple preparation method and good physical and chemical properties.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

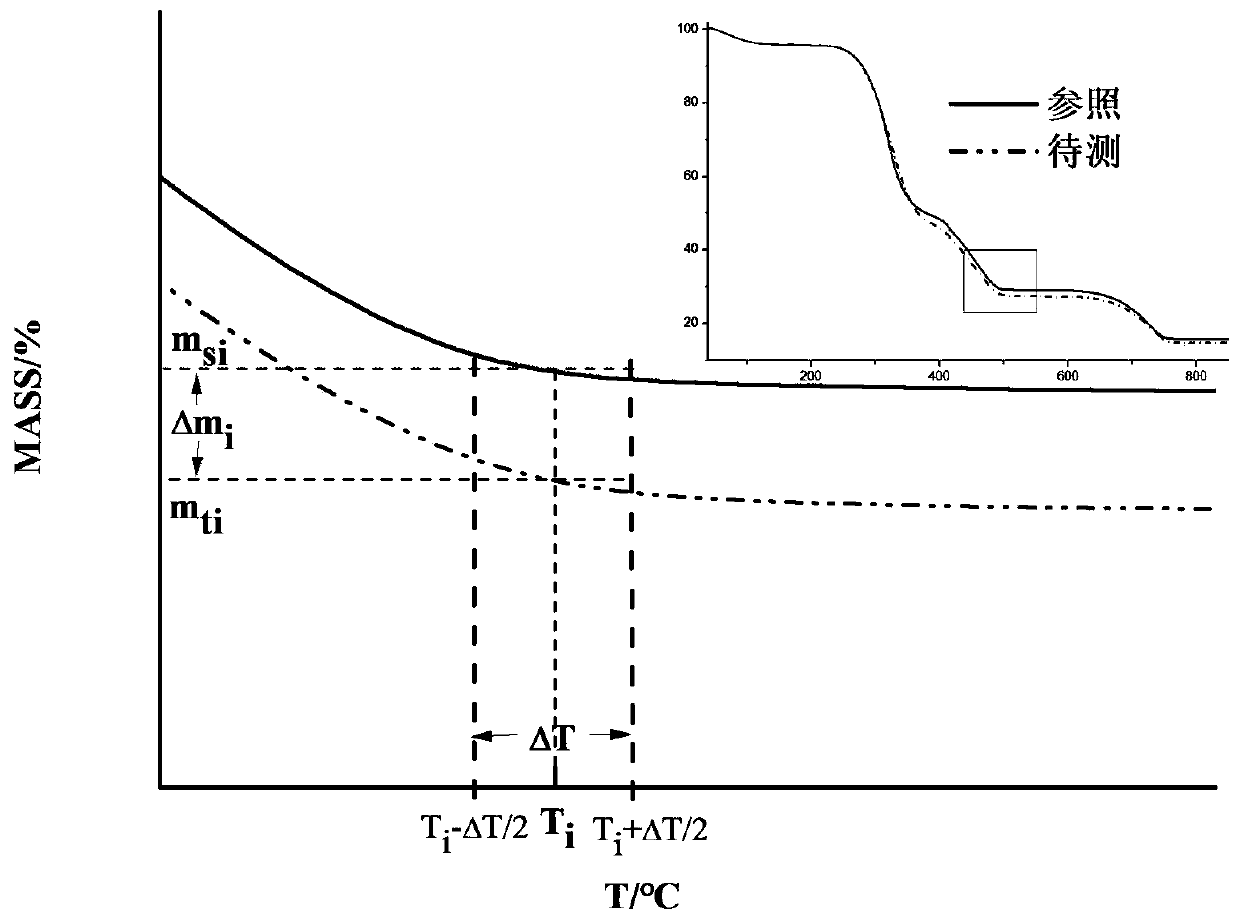

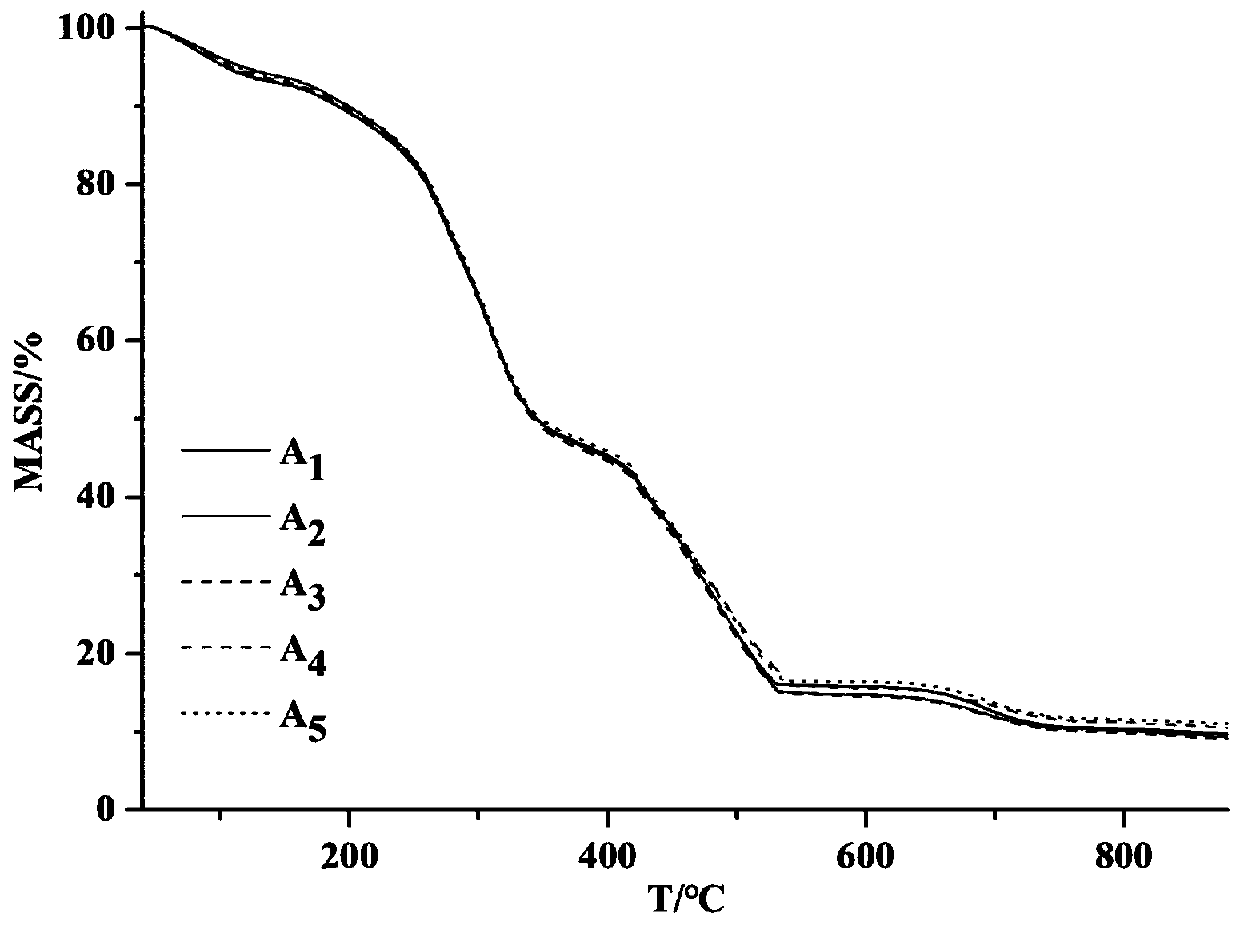

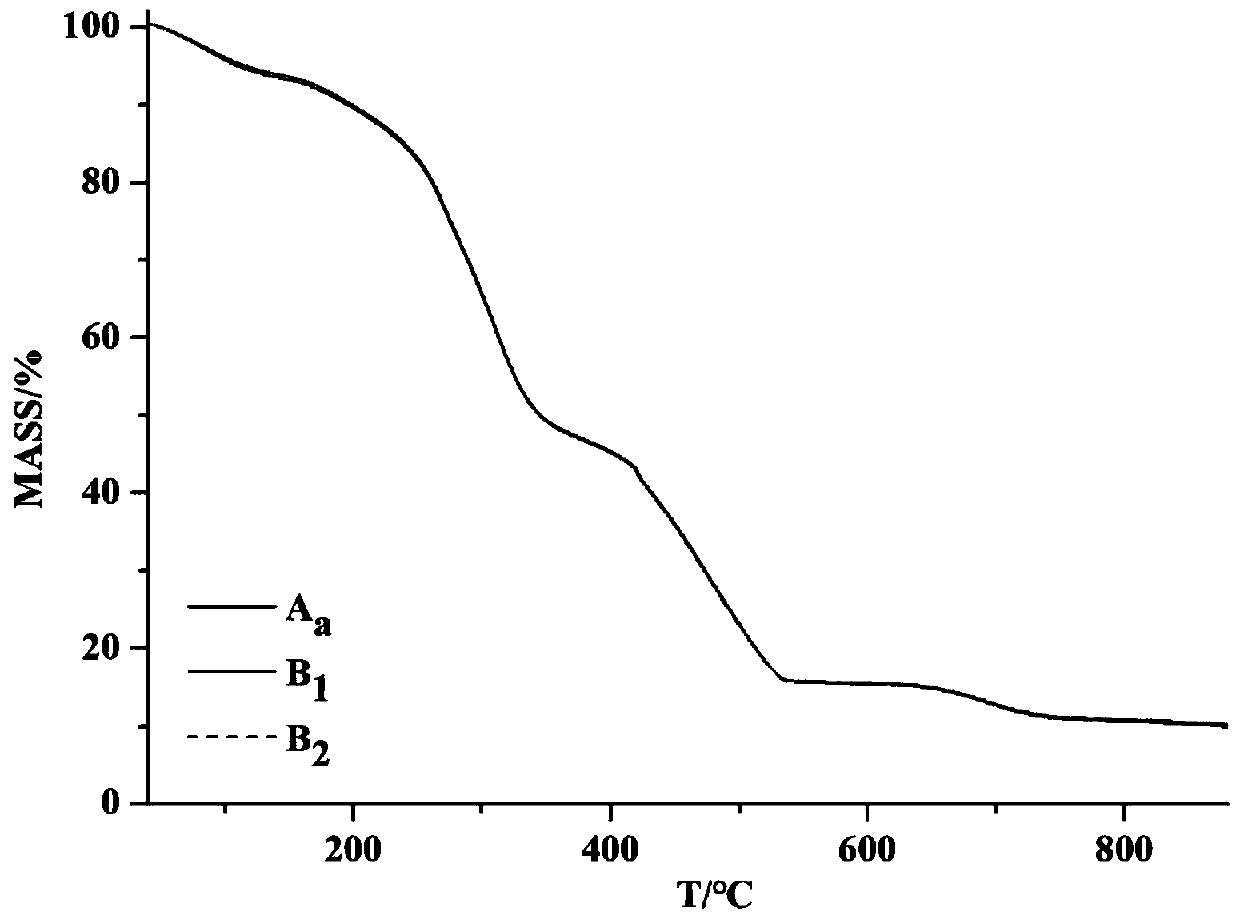

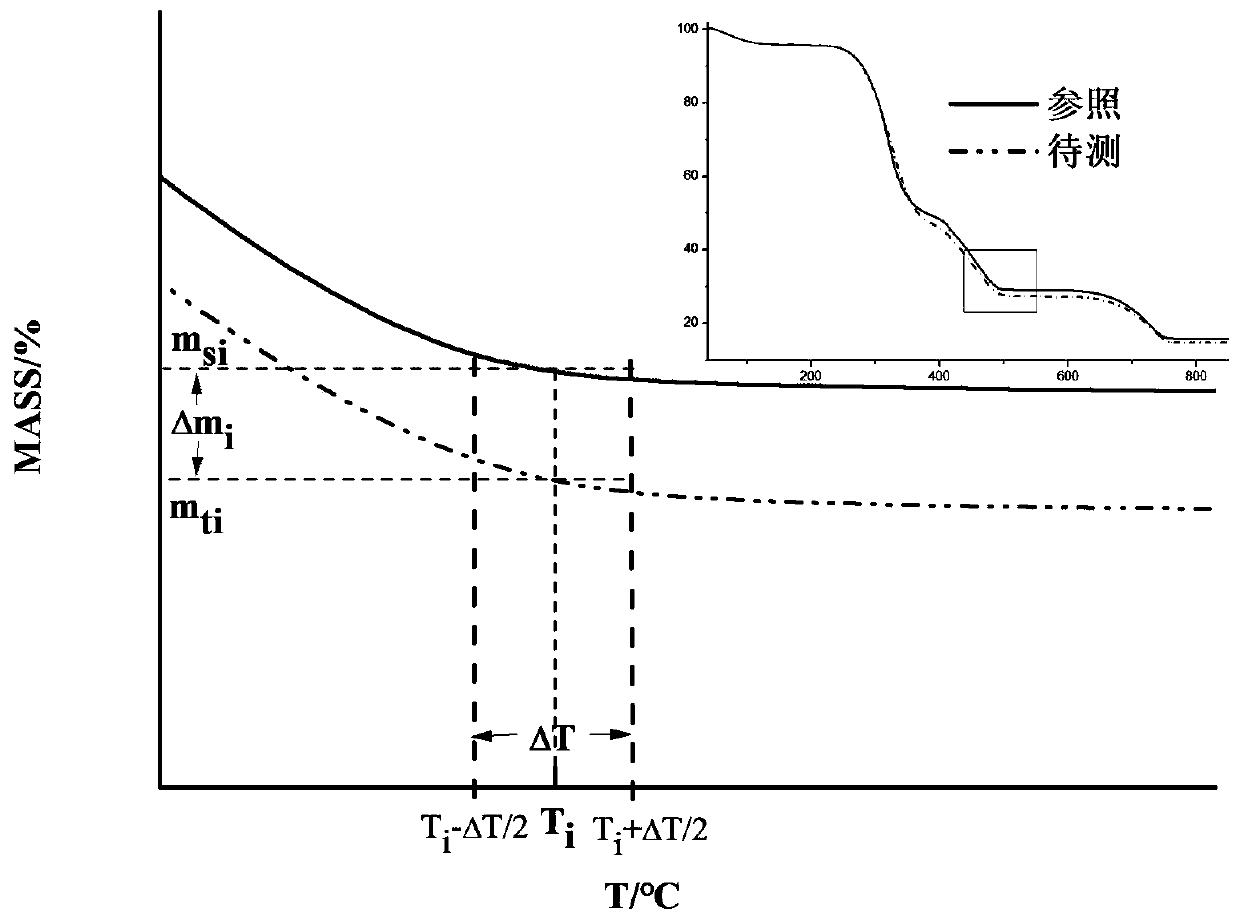

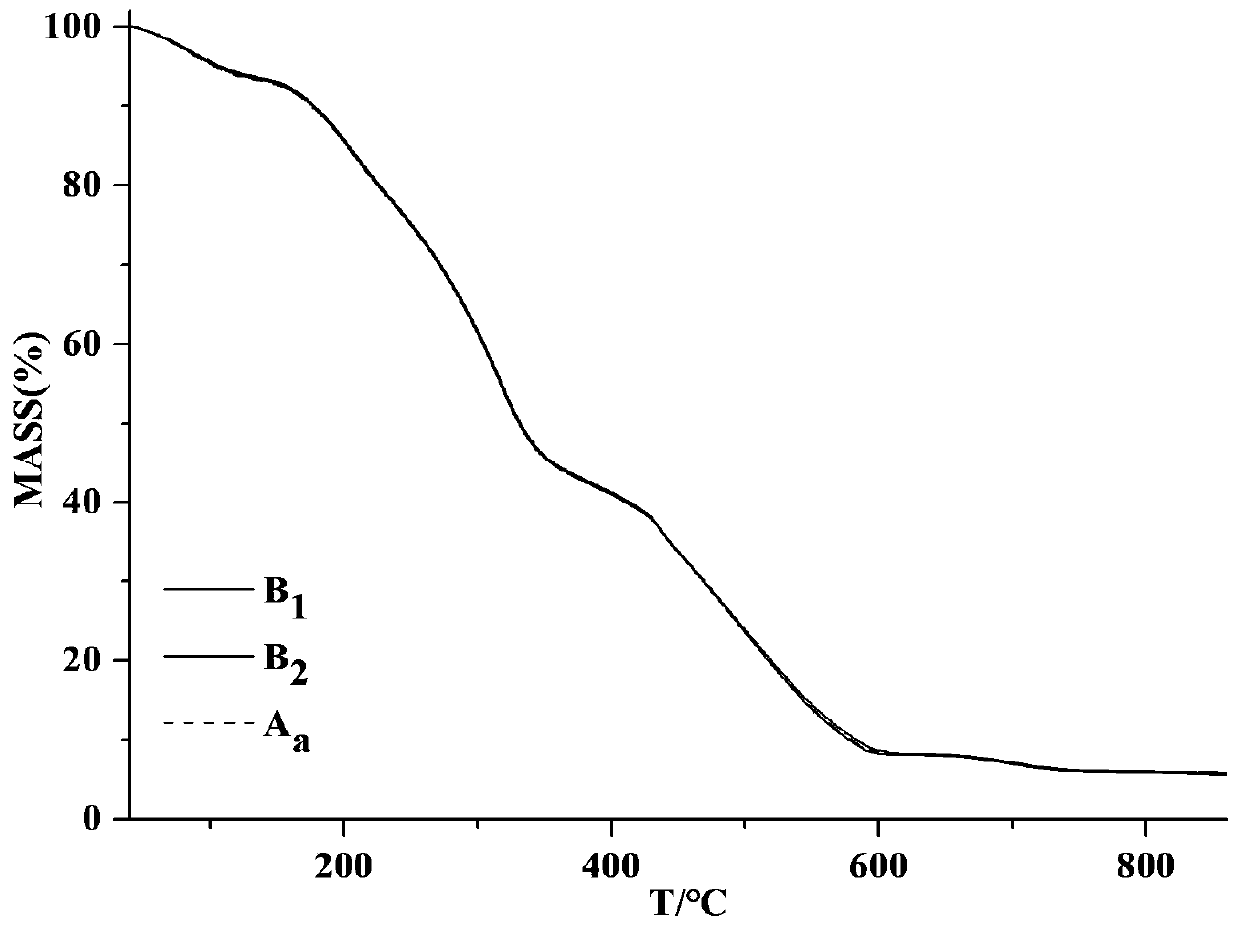

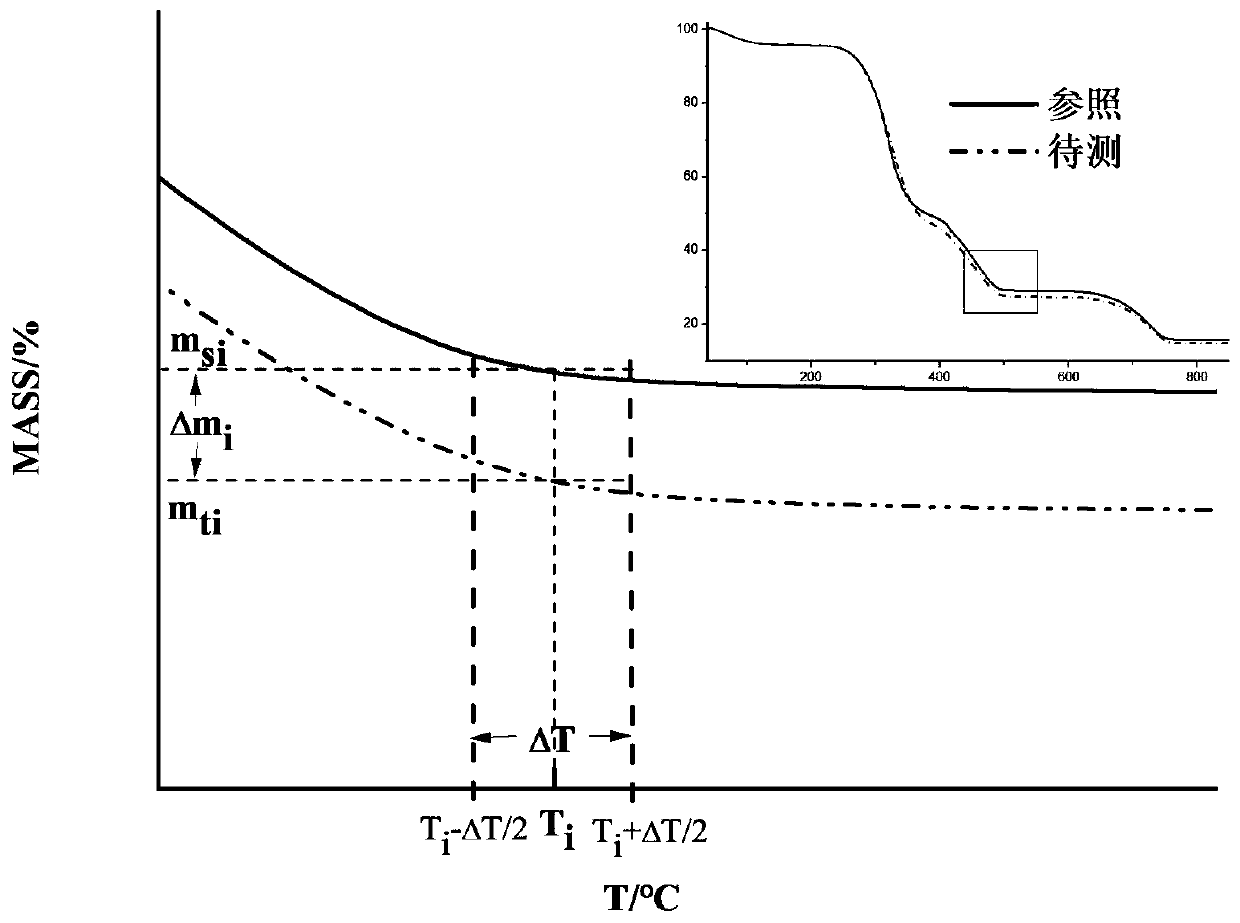

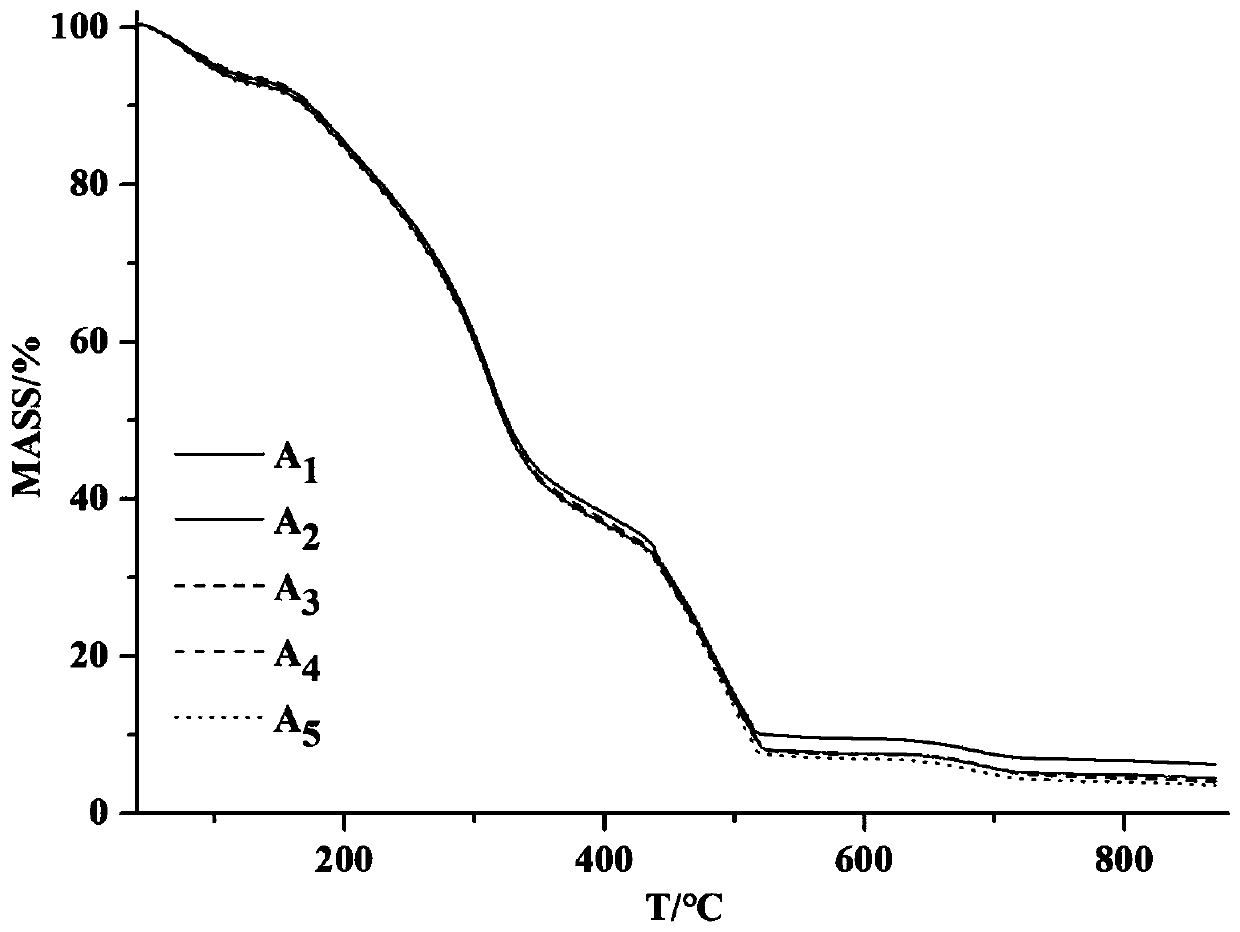

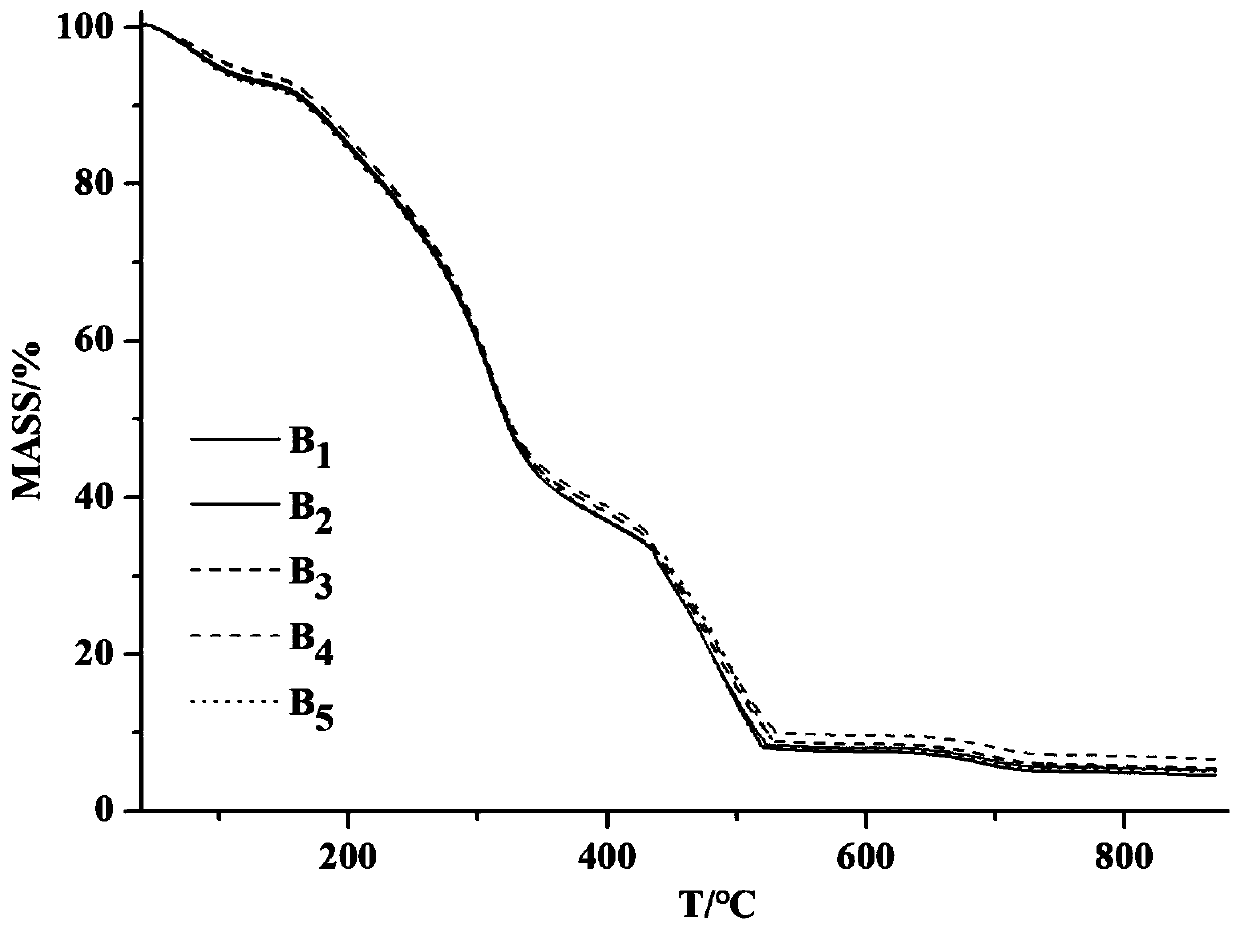

A Method for Evaluating the Quality Stability of Reconstituted Tobacco Leaf Between Batches

ActiveCN108061691BEasy to handleExperimental results are objectiveWeighing by removing componentReference sampleProcess engineering

The invention discloses a method for evaluating the quality stability of batch-to-batch reconstituted tobacco, and is used for judging the quality stability of batch-to-batch reconstituted tobacco ofsame brand and specification. The method is characterized by comprising the following steps: taking two batches of reconstituted tobacco of same brand and specification as a reference sample and a sample to be tested respectively, and judging the quality stability of the sample to be tested relative to the reference sample by contrasting the thermal weight loss TG curve of the reference sample andthe thermal weight loss TG curve of the sample to be tested. According to the method, a thermal gravimetric analyzer is used for judging the quality stability of batch-to-batch reconstituted tobacco,the similarity of the thermal weight loss curve of the reference reconstituted tobacco sample and the thermal weight loss curve of the reconstituted tobacco sample to be tested is compared, the similarity threshold value of the concept thermal weight loss curve is firstly introduced as the judgment basis of the quality stability of batch-to-batch reconstituted tobacco, and a feasible method is provided for judging the quality stability of batch-to-batch reconstituted tobacco; the equipment and operation processing used in the invention are simple, no chemical reagent does not need to be used,the quantity of required sample is small, and the experimental result is objective and accurate.

Owner:CHINA TOBACCO ANHUI IND CO LTD

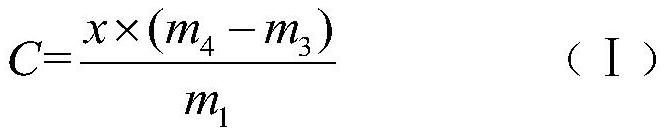

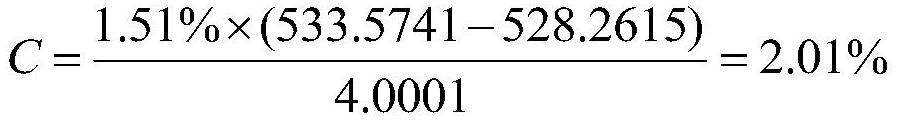

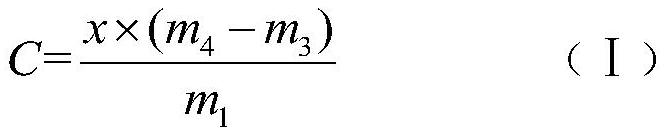

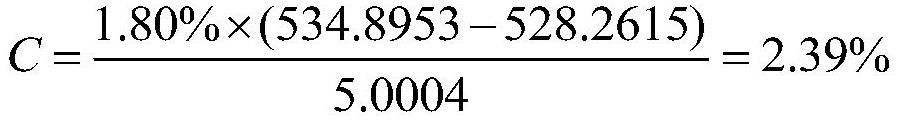

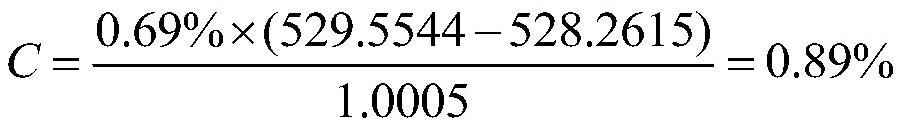

A method for testing the content of inorganic functional powder in functional polyester

ActiveCN109060583BEasy to operateReliable resultsWeighing by removing componentDimethyl terephthalatePolyester

The invention relates to the field of quantitative analysis of functional polyester, in particular to a method for testing the content of inorganic functional powder in functional polyester. The method for testing the content of inorganic functional powder in the functional polyester specifically comprises the steps that the functional polyester is depolymerized into dimethyl terephthalate, glycoland inorganic functional powder by a supercritical methanol depolymerization method; then a thermal gravimetric analyzer is used for testing a thermal weight loss mass residual rate of the functionalpolyester product depolymerized by the supercritical methanol in a heating temperature range of 284-400 DEG C; and finally, the content of the inorganic functional powder in the functional polyesteris calculated according to the thermal weight loss mass residual rate. According to the method for testing the content of inorganic functional powder in the functional polyester, the content of the inorganic functional powder in the functional polyester can be measured accurately, and the problem that an existing method cannot accurately measure the content of the inorganic functional powder in the functional polyester is solved. Moreover, the method for testing the content of inorganic functional powder in the functional polyester is simple to operate, does not need complicated instruments and equipment, and has accurate and reliable results and good reproducibility.

Owner:CHINESE TEXTILE ACAD

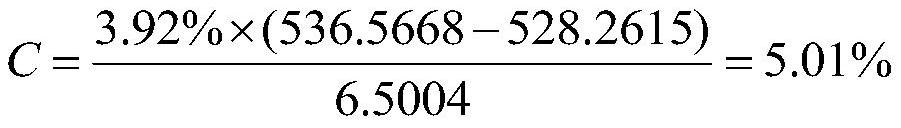

A test method for pigment content in dope dyed polyester

ActiveCN109060582BEasy to operateReliable resultsWeighing by removing componentDimethyl terephthalatePolyester

The invention belongs to the field of quantitative analysis of stock solution pigmented polyester, and particularly relates to a test method for pigment content of stock solution pigmented polyester.The test method comprises the following specific steps: depolymerizing the stock solution pigmented polyester into dimethyl terephthalate, diol and pigments by a supercritical methanol depolymerization method; then, testing the thermal weight loss mass residue rate of a supercritical methanol depolymerized stock solution pigmented polyester product in a heating temperature segment of 284 to 400 DEG C by a thermal gravimetric analyzer; and finally, calculating the pigment content of the stock solution pigmented polyester according to the thermal weight loss mass residue rate. Through adoption of the test method, the pigment content of the stock solution pigmented polyester can be accurately measured, and the problem that the existing methods cannot accurately measure the pigment content ofthe stock solution pigmented polyester is solved. Moreover, the test method provided by the invention has the advantages of easiness in operation, no need for complicated instruments and equipment, accurate and reliable results and high reproducibility.

Owner:CHINESE TEXTILE ACAD

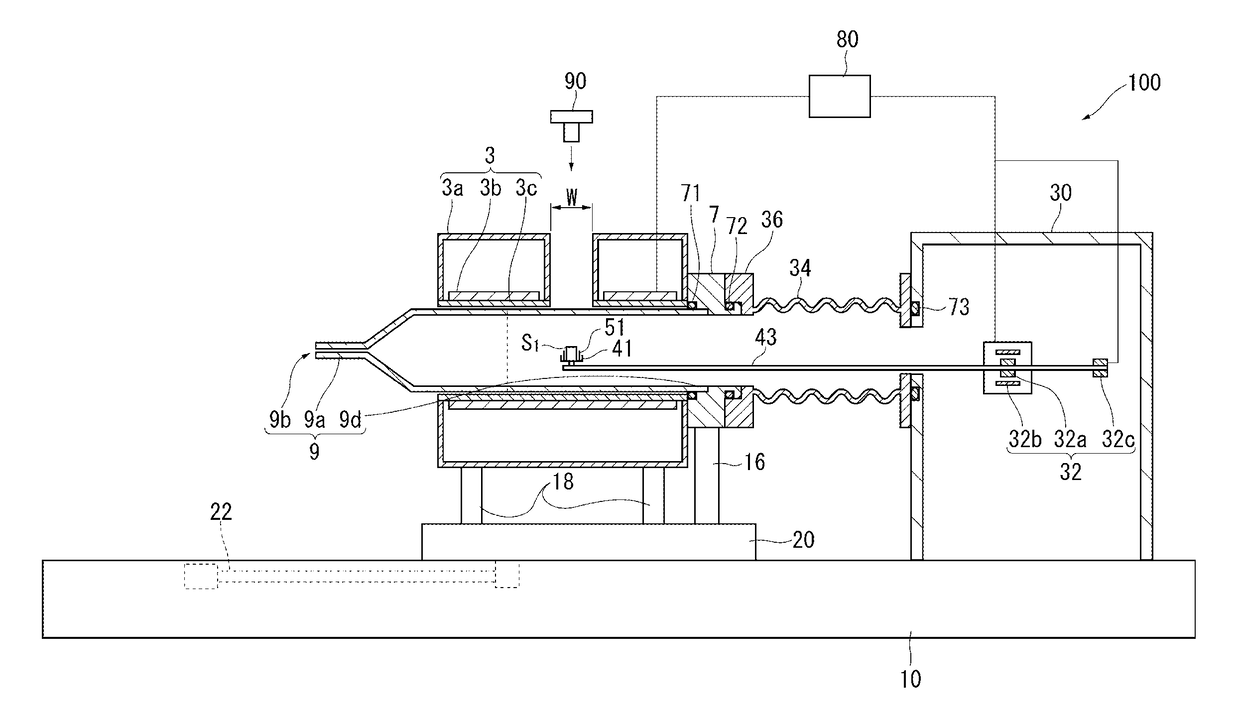

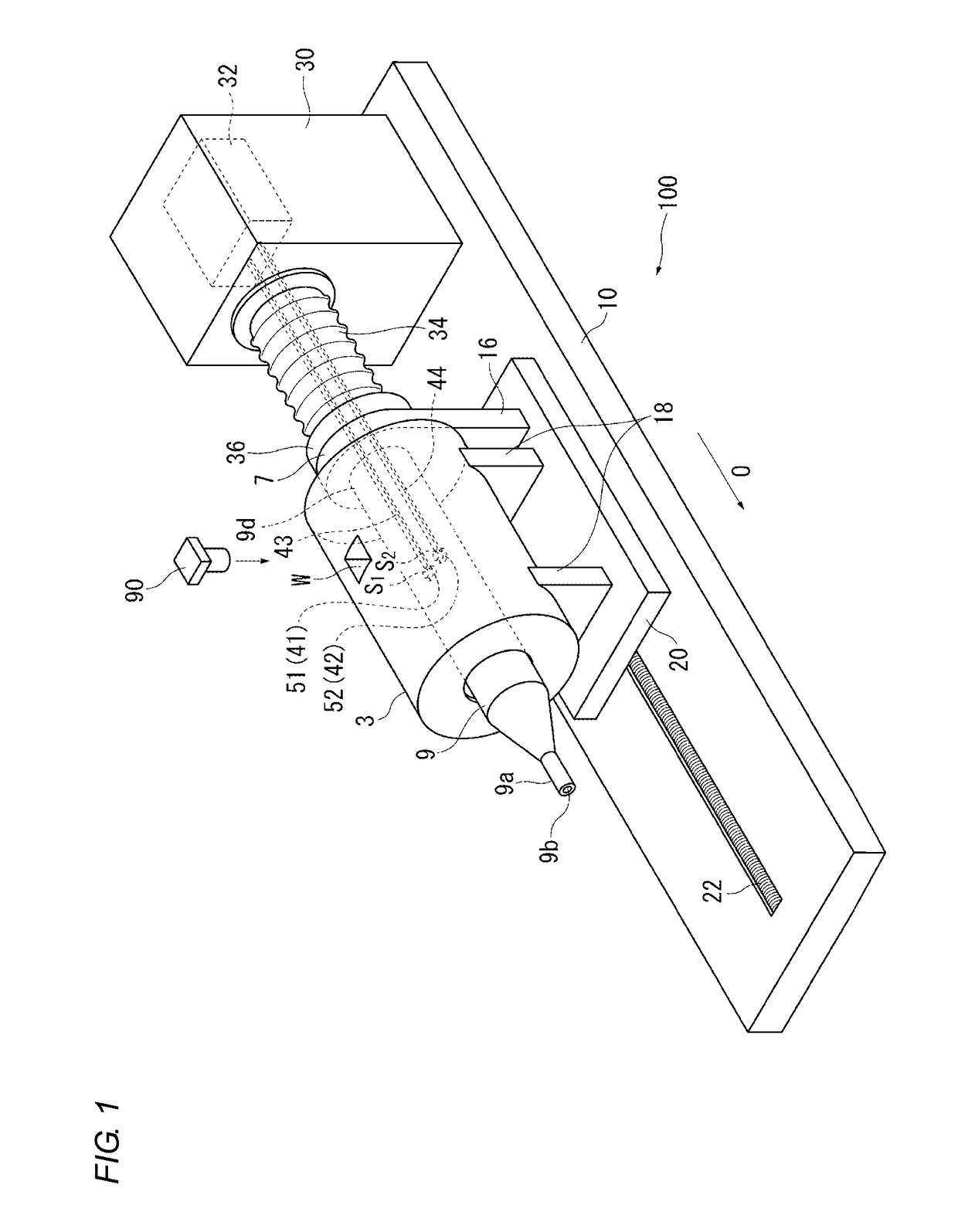

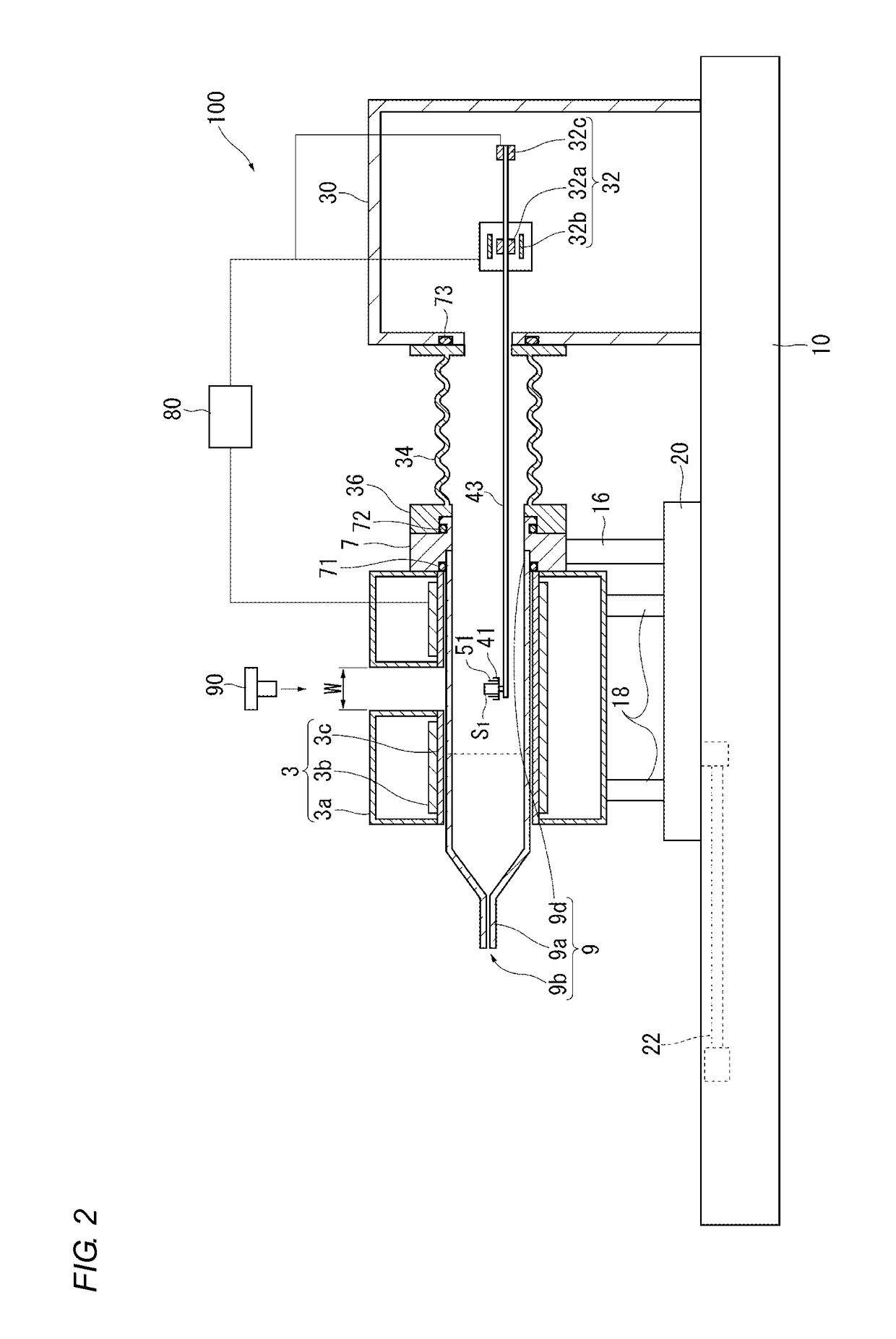

Thermo-gravimetric apparatus

ActiveUS10088402B2High measurement accuracyWeighing by removing componentMaterial thermal analysisHeating furnaceGravitation

A thermal analyzer is provided with: a furnace tube; a pair of sample holders; a heating furnace; a measurement chamber; and a measurement unit arranged inside the measurement chamber. The sample holders are arranged inside the furnace tube and are provided with mounting faces on which a pair of sample containers are mounted respectively. The heating furnace has an opening through which a measurement sample is observable, the opening being located at a position above the center of a virtual segment which connects centers of gravity of the mounting faces of the sample holders. The opening is formed to have a size, as viewed in a direction perpendicular to the axial direction and the mounting faces, of 7 mm or more in the direction along the virtual segment and of 3 mm or more in the direction perpendicular to the virtual segment.

Owner:HITACHI HIGH TECH SCI CORP

A method for evaluating the quality stability of finished cigarettes between batches

ActiveCN108120653BEasy to handleExperimental results are objectiveWeighing by removing componentReference sampleTest sample

The invention discloses a method for evaluating the quality stability of product cigarettes among batches for judging the quality stability of product cigarettes among batches and specifications of same brand. The method is characterized by comprising the following steps: extracting the product cigarettes of two batches of same brand and specification as a reference sample and a to-be-tested sample; and judging the quality stability of the to-be-tested sample relative to the reference sample by comparing thermal weight loss TG curves of the reference sample and the to-be-tested sample. A thermal gravimetric analyzer is used for judging the quality stability of product cigarettes among batches. By comparing the similarity of the thermal weight loss curves of the reference sample and the to-be-tested sample, a concept of thermal weight loss curve similarity threshold value is introduced for the first time as a judging ground of the quality stability of product cigarettes among batches, thereby providing a feasible method for judging the quality stability of product cigarettes among batches. The used equipment and operations are simple, no chemical reagents are used, the amount of needed samples is small, and the experimental result is objective and accurate.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Formula and preparation technology of modified polyurethane

InactiveCN107840997AEasy to integrateIncrease coefficient of frictionSport apparatusGlass transitionMuffle furnace

The invention discloses a formula of modified polyurethane. The formula comprises, by weight, 50 to 60 parts of iron tailings, 3 to 4 parts of sodium carbonate, 5 to 6 parts of calcium oxide, 2 to 3 parts of borax, 30 to 40 parts of quartz sand and 8 to 9 parts of alumina. A preparation method of the modified polyurethane comprises putting raw materials prepared according to the formula into a planetary ball mill, carrying out ball milling mixing for 1.5h, putting the mixture into a corundum crucible, heating the mixture to 1450-1500 DEG C in a muffle furnace at a heating rate of 5-6 DEG C / min, keeping the temperature of 1450-1500 DEG C for 3-4h, pouring a part of molten glass into water, carrying out water quenching, putting the other part of the molten glass into a mold preheated to 600DEG C, after molding and releasing, fast putting the model into the muffle furnace, carrying out annealing at 600 DEG C for 5h, grinding the glass subjected to water quenching to obtain powder of 74 microns, measuring a DSC curve through a thermal gravimetric analyzer, increasing the room temperature to 1000 DEG C, determining an endothermic valley and an exothermic peak, wherein the endothermic valley represents a glass transition temperature and the exothermic peak represents a crystallization temperature, determining the optimum nucleation temperature and the crystallization temperature ofthe microcrystalline glass according to the DSC curve and carrying out crystallization and nucleation.

Owner:杨磊

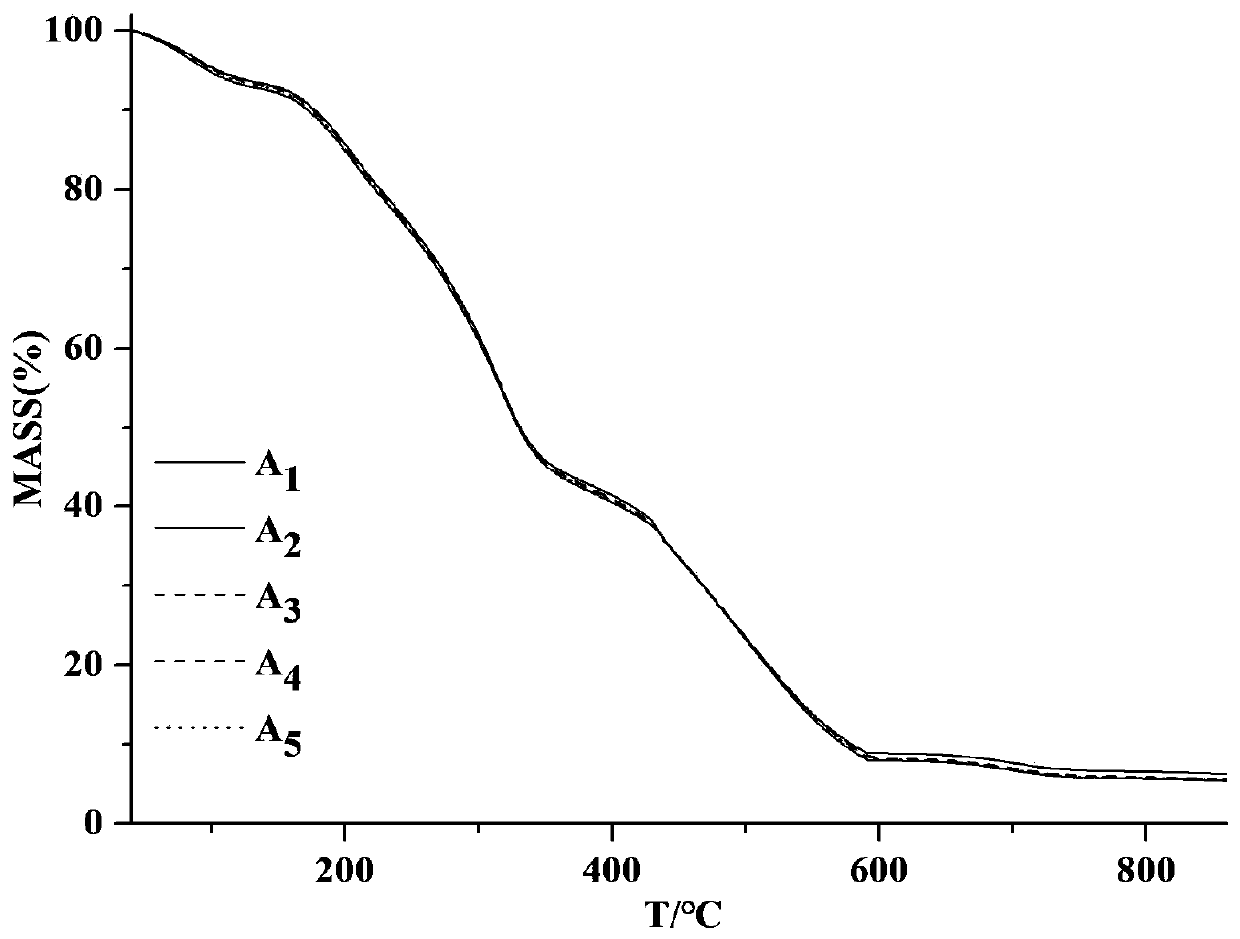

A method for measuring blending uniformity of shredded tobacco in cigarettes

ActiveCN108195711BSimple equipmentSimple processing capacityWeighing by removing componentProcess engineeringIndustrial engineering

The invention discloses a method for measuring the blending uniformity of cigarette cut tobacco. The method is characterized by comprising the following steps: within the production time of one batch,taking flavored blended cut tobacco to carry out thermal weight loss testing five times at same intervals, calculating the similarity between every two obtained sample thermal weight loss TG curves and the variable coefficient between the similarities, and thus measuring the blending uniformity of cigarette cut tobacco. A thermal gravimetric analyzer is creatively used for the measurement of theblending uniformity of cigarette cut tobacco, the used equipment and operation treatment are simple, and neither tracer nor chemical reagent is needed; the quantity of the required sample in small; the method is quantitatively described and objective and accurate in experimental result; according to method principle, the method is applicable for any blending system.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com