Microwave material science workstation

A microwave material and workstation technology, applied in microwave heating and other directions, can solve the problems of a single heating cavity and a single heating method, and achieve powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

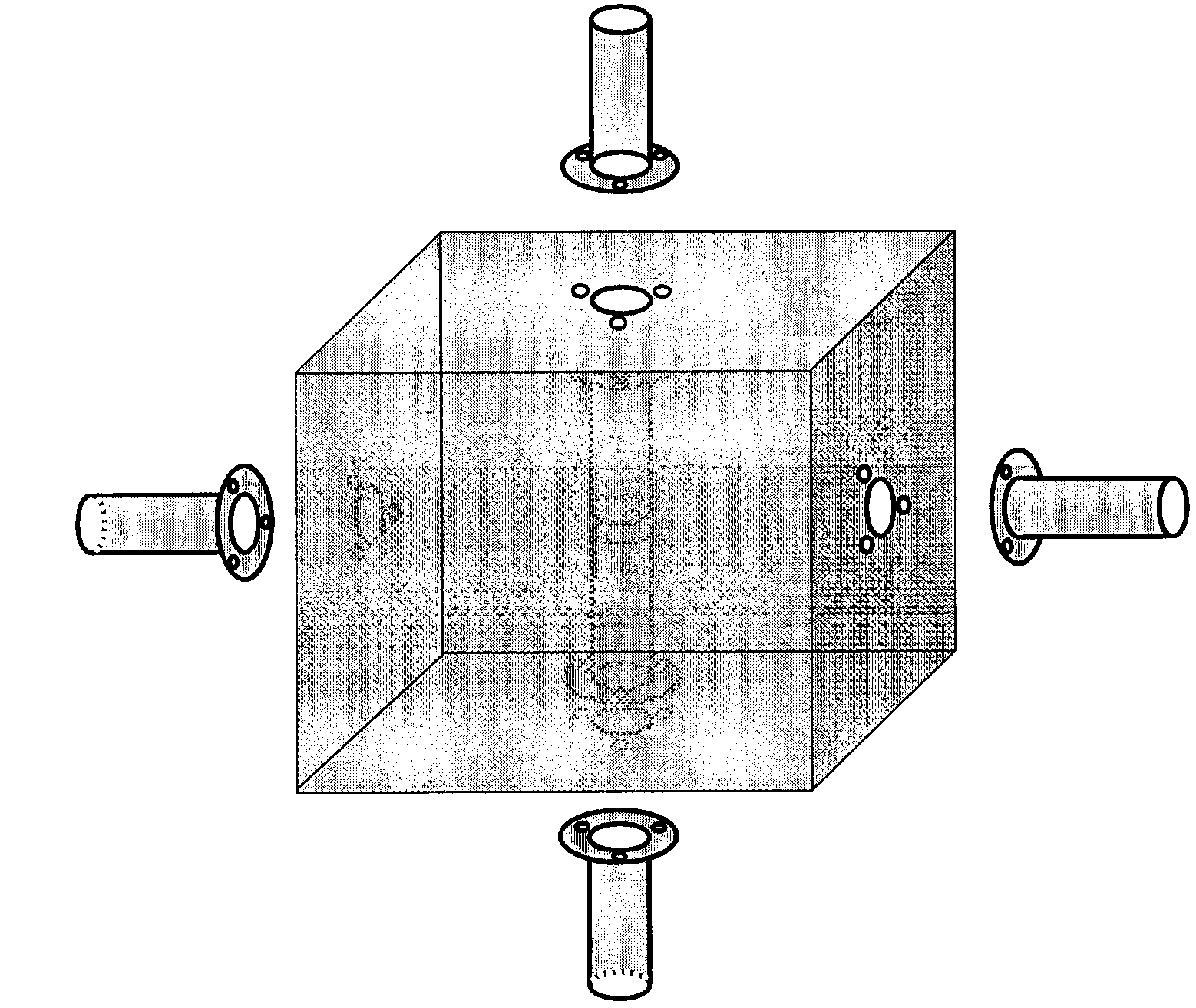

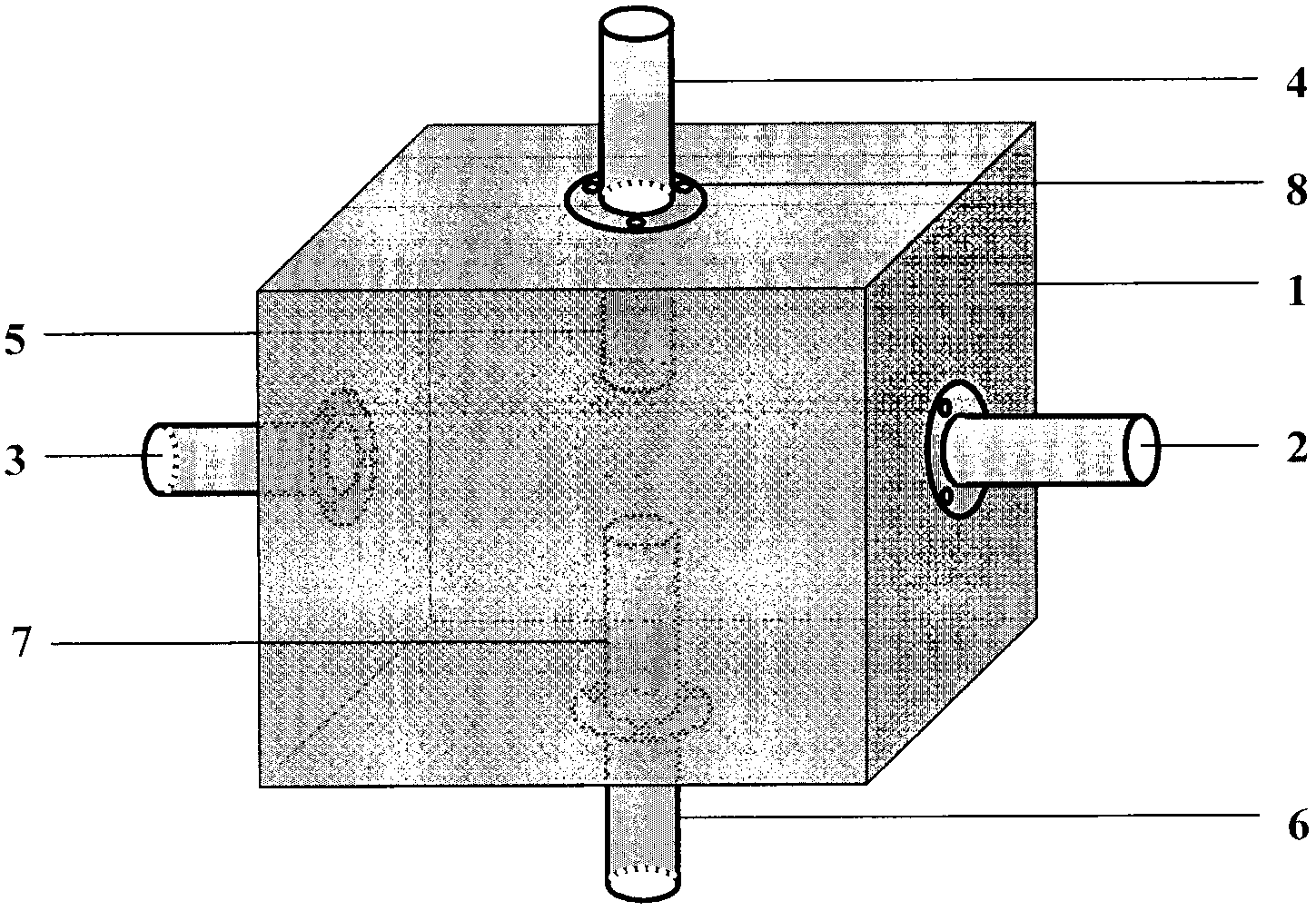

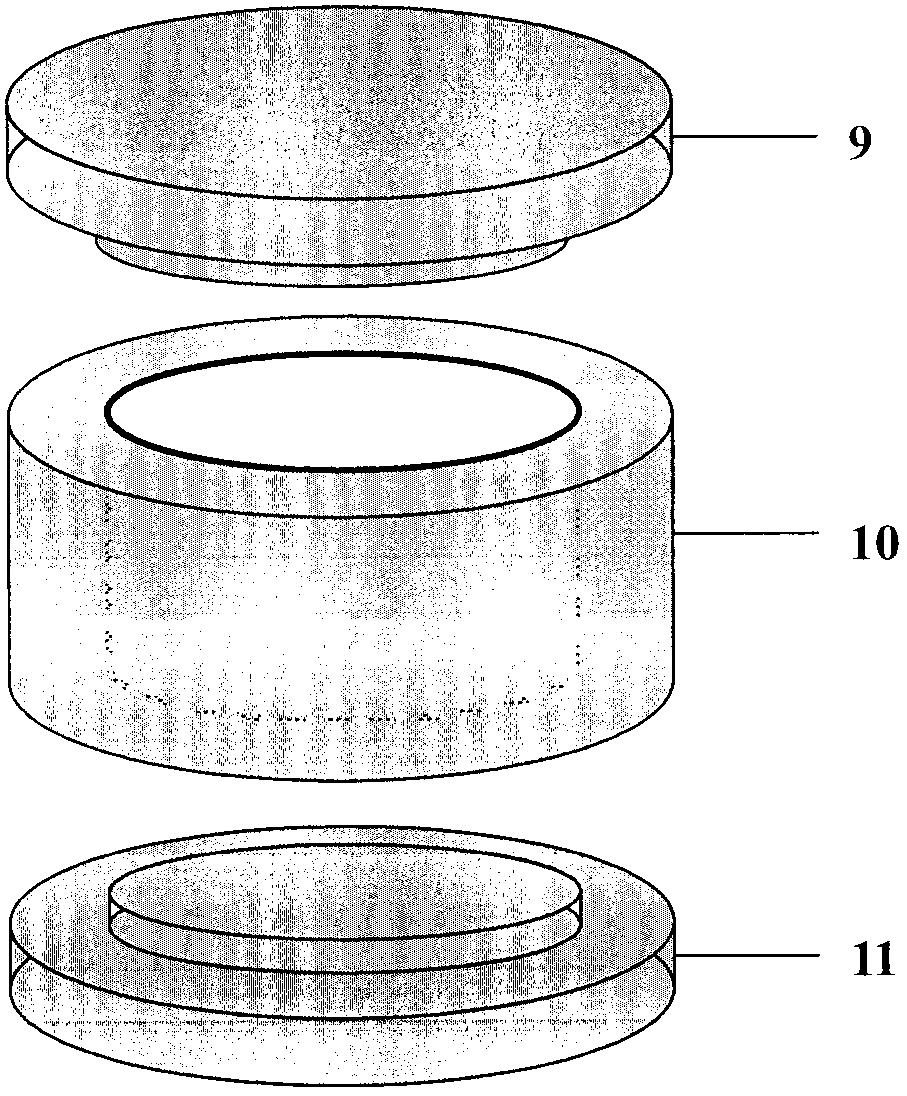

[0059] The schematic diagram of the main structure and functional interface structure of the microwave materials science workstation in the first embodiment of the present invention is shown in FIG. 1 . It consists of a microwave-enclosed metal cavity 1, A-F type functional interfaces 2-7, a heating cavity with modular functions, a microwave generation and control system (not shown in the figure), a temperature measurement and control system (not shown in the figure) 1. Air-cooling system (not shown in the figure), the microwave generated by the magnetron is introduced into the metal cavity. The working voltage of the microwave materials science workstation: 220V, microwave power 4KW, microwave frequency: 2450MHz. The metal cavity 1 is made of 2mm thick 304 stainless steel, and the upper opening of the metal cavity 1 is equipped with a furnace door structure (not shown in the figure). Functional interface 2 and B-type functional interface 3, after opening a hole in the middle...

Embodiment 2

[0073] The schematic diagram of the main structure and functional interface structure of the microwave materials science workstation in the second embodiment of the present invention is as follows Figure 15 shown. It consists of a microwave-enclosed metal cavity 1, A-C type functional interfaces 2-4, a heating cavity with modular functions, a microwave generation and control system (not shown in the figure), a temperature measurement and control system (not shown in the figure) 1. Air-cooling system (not shown in the figure), the microwave generated by the magnetron is introduced into the metal cavity. The working voltage of the microwave material science workstation is 220V, the microwave power is 2KW, and the microwave frequency is 2450MHz. The metal cavity 1 is made of 2mm thick 304 stainless steel, and the upper opening of the metal cavity 1 is equipped with a furnace door structure (not shown in the figure). Functional interface 2 and B-type functional interface 3. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com