A wo3/v2o5/fto composite photoelectrode and its preparation and use method

A composite light and electrode technology, applied in chemical instruments and methods, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of easy powder agglomeration, narrow application range, narrow light frequency, etc. The raw materials and operation process are simple, the labor labor is reduced, and the spinning speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

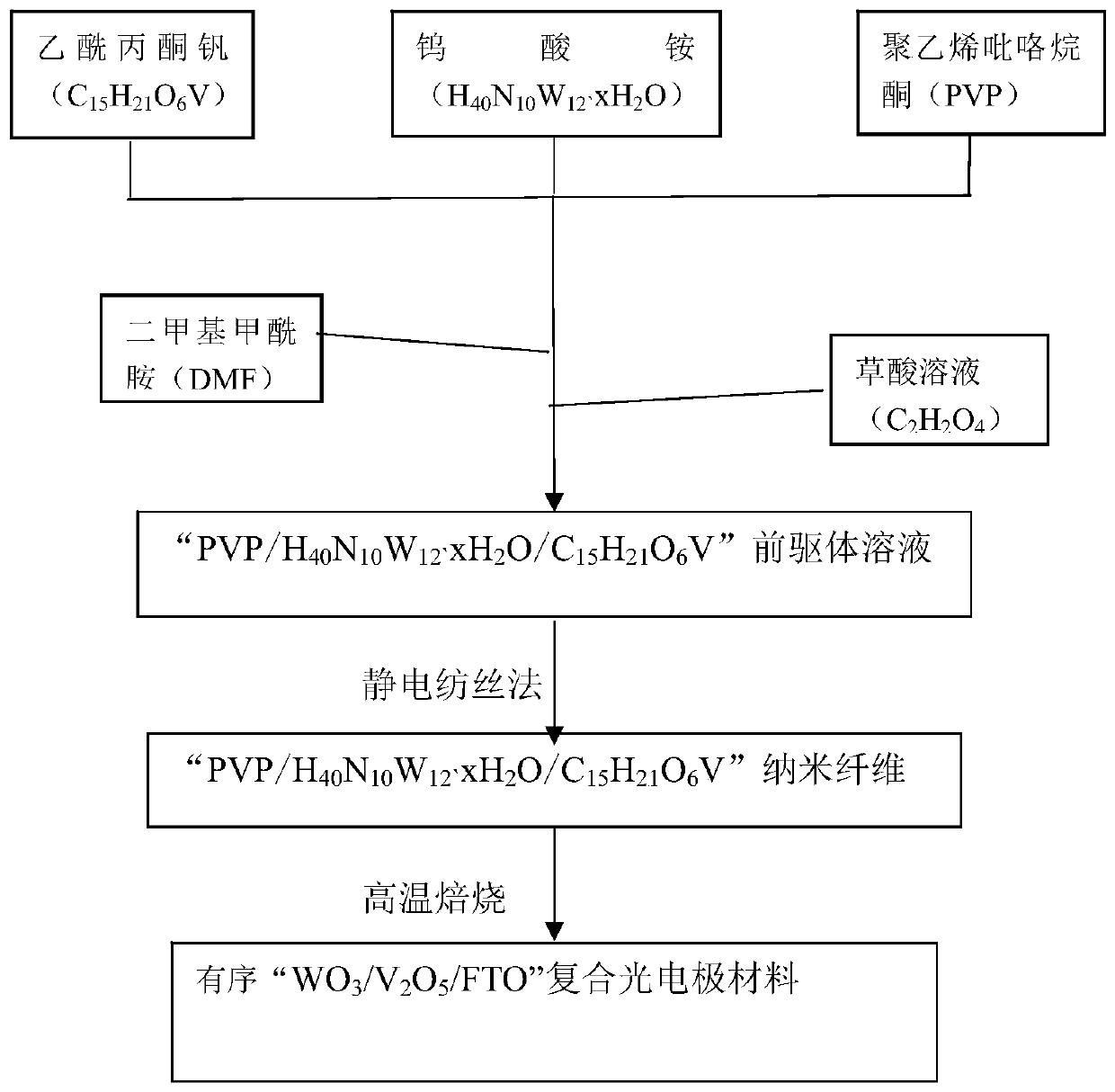

[0029] The preparation process is as image 3 shown

[0030] (1) Preparation of precursor sol: weigh 0.1000g C with an electronic balance 15 h 21 o 6 Dissolve V in 4mL DMF, seal it and stir until completely dissolved; weigh 0.0728g H 40 N 10 W 12 ·xH 2 Dissolve O in 1mL of 0.1g / mL oxalic acid solution, seal it until dissolved; weigh 0.8000g PVP, dissolve it in 4mL DMF, seal it and stir until completely dissolved; mix the above three solutions, seal and stir until transparent to obtain n Viscous PVP / H with (V) / n(W) 1:1 40 N 10 W 12 ·xH 2 O / C 15 h 21 o 6 V precursor sol.

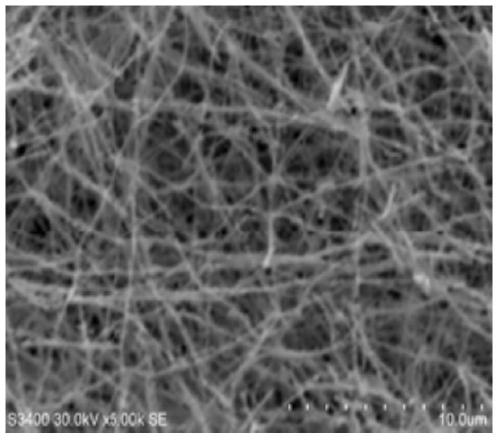

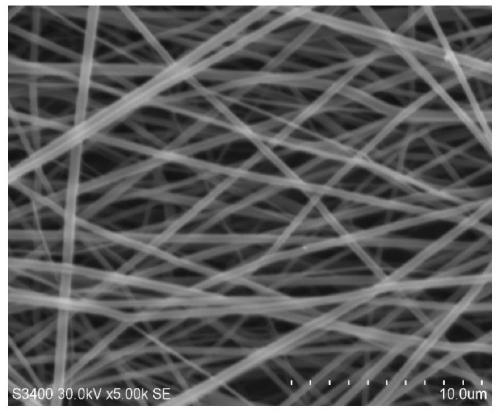

[0031] (2) Electrospinning: Inhale the precursor sol configured in step (1) into the syringe, clamp the metal electrode at the front end of the syringe at 2.0 cm, adjust the tilt angle of the syringe so that it forms an angle of 90° with the horizontal plane, and place the The temperature is ≤25°C, the humidity is ≤30%, and the distance between the needle of the syringe and the receiving conduct...

Embodiment 2

[0037] (1) Preparation of precursor sol: weigh 0.1000g C with an electronic balance 15 h 21 o 6 Dissolve V in 4mL DMF, seal it and stir until completely dissolved; weigh 0.1456g H 40 N 10 W 12 ·xH 2 O was dissolved in 2mL of 0.1g / mL oxalic acid solution, and sealed until it was completely dissolved; 0.9000g of PVP was weighed and dissolved in 5mL of DMF, sealed and stirred until completely dissolved; the above three solutions were mixed, sealed and stirred until transparent to obtain Viscous PVP / H with n(V) / n(W) 1:2 40 N 10 W 12 ·xH 2 O / C 15 h 21 o 6 V precursor sol.

[0038] (2) Electrospinning: Inhale the precursor sol configured in step (1) into the syringe, clamp the metal electrode at the front end of the syringe at 1.8 cm, adjust the tilt angle of the syringe so that it forms an angle of 100° with the horizontal plane, and place the The temperature is 32°C, the humidity is ≤28%, the distance between the needle of the syringe and the receiving conductive glas...

Embodiment 3

[0043] (1) Preparation of precursor sol: weigh 0.1000g C with an electronic balance 15 h 21 o 6 Dissolve V in 4mL DMF, seal it and stir until completely dissolved; weigh 0.2912g H 40 N 10 W 12 ·xH 2 O was dissolved in 4mL of 0.1g / mL oxalic acid solution, sealed until completely dissolved; weighed 1.0000g PVP, dissolved in 6mL DMF, sealed and stirred until completely dissolved; mixed the above three solutions, sealed and stirred until transparent to obtain n Viscous PVP / H with a (V) / n(W) ratio of 1:4 40 N 10 W 12 ·xH 2 O / C 15 h 21 o 6 V precursor sol.

[0044] (2) Electrospinning: Inhale the precursor sol configured in step (1) into the syringe, clamp the metal electrode at the front end of the syringe at 1.3 cm, adjust the tilt angle of the syringe so that it forms an angle of 120° with the horizontal plane, and place the Temperature ≤ 34°C, humidity ≤ 25%, adjust the distance between the syringe needle and the receiving conductive glass to 18cm, apply 13kV positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com