Method for judging thermo-crosslinking process scope of thermoplastic polymer

A thermoplastic polymer and thermal crosslinking technology, applied in the field of new technology development, can solve the problems of lack of universality and complexity in the chemical structure analysis of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

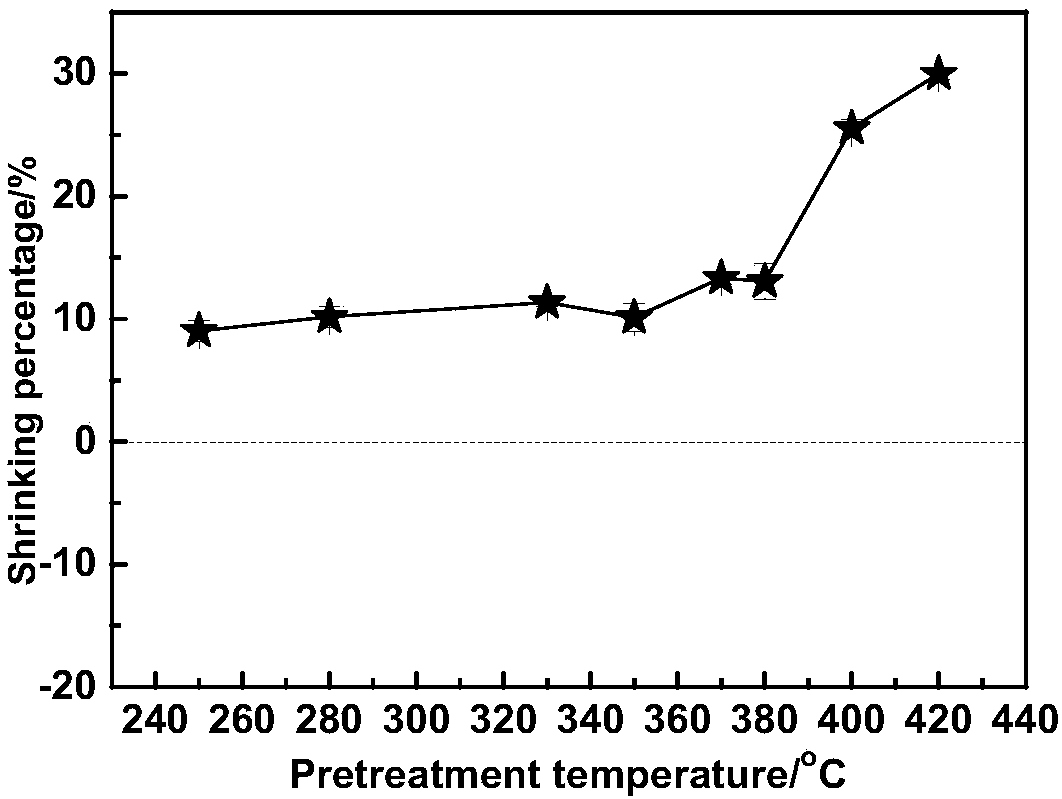

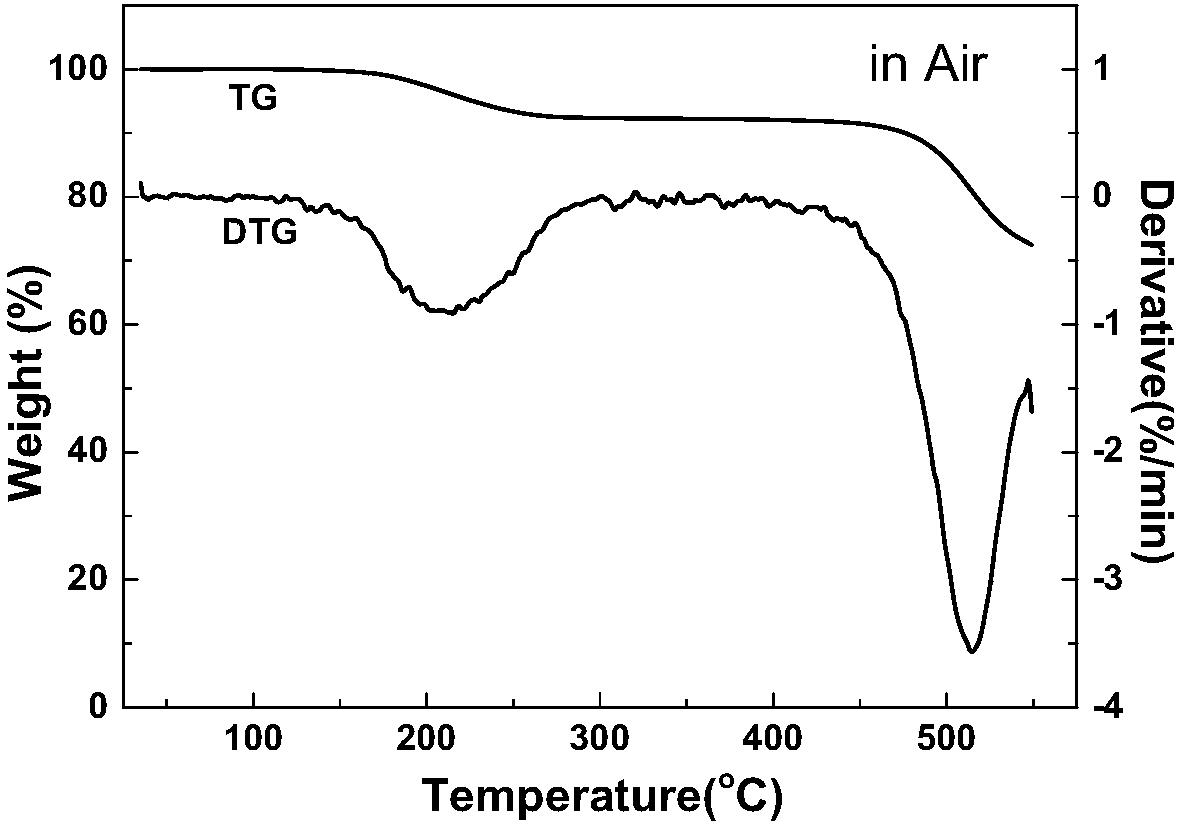

[0041] According to attached figure 1 As shown, the crosslinking process conditions for the upper limit of the optimal thermal crosslinking degree of thermoplastic polymer polyaryletherketone are: thermal crosslinking temperature is 380°C, heating rate is 3°C / min, constant temperature time is 30min, and the crosslinking atmosphere is air , the air flow rate is 200ml / min.

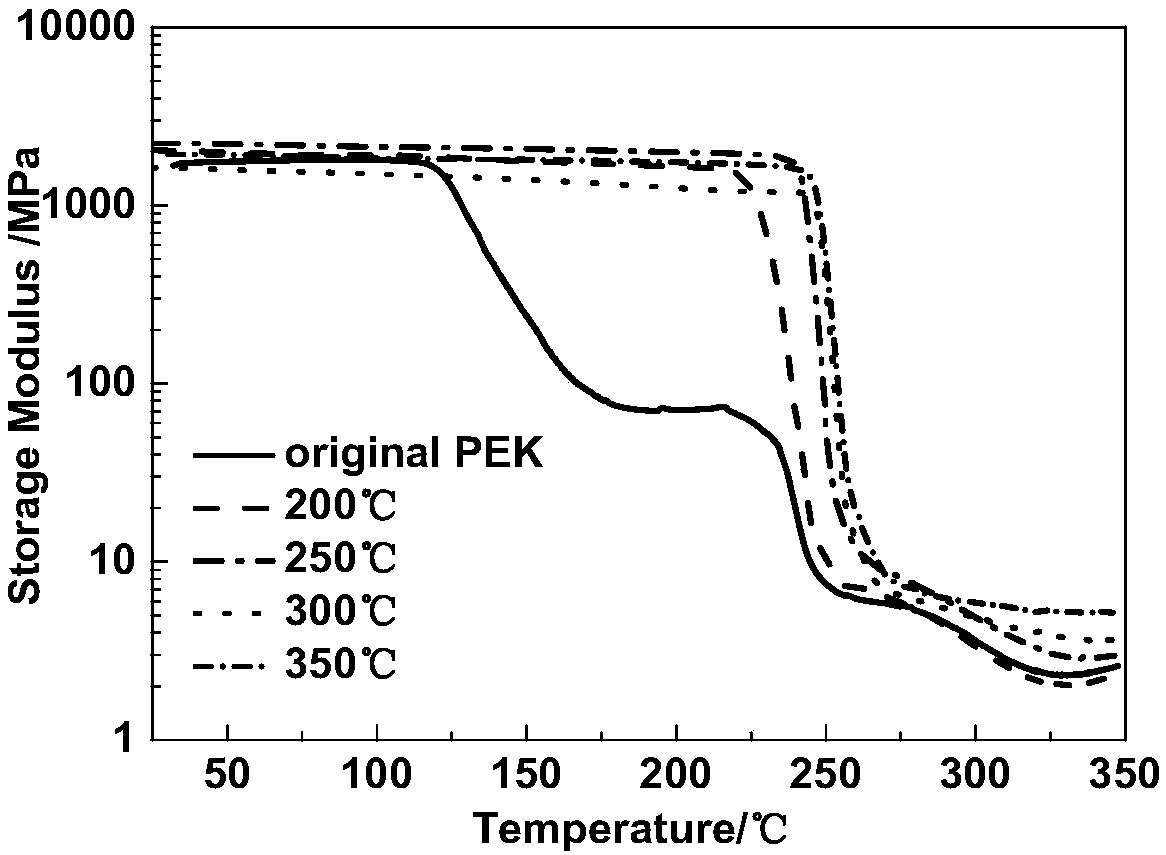

[0042] according to image 3 As shown, the cross-linking process conditions for the optimal thermal cross-linking degree lower limit of the thermoplastic polymer polyaryletherketone are: thermal cross-linking temperature is 350 °C, cross-linking heating rate is 3 °C / min, constant temperature time is 30 min, cross-linking atmosphere For air, the air flow rate is 200ml / min.

[0043] Therefore, the optimal thermal crosslinking degree process of thermoplastic polymer polyaryletherketone is: thermal crosslinking temperature is 350-380°C, crosslinking heating rate is 3°C / min, constant temperature time is 30min, ...

Embodiment 2

[0045] According to attached figure 2 Shown, the crosslinking process condition of the upper limit of the optimum thermal crosslinking degree of thermoplastic polymer polyaryletherketone is: thermal crosslinking temperature is 430 ℃, and heating rate is 10 ℃ / min, constant temperature time 0min (described in the present invention The constant temperature time is 0, which means that the temperature is not kept warm after the temperature reaches the target temperature, but the heating is stopped directly), the crosslinking atmosphere is air, and the air flow rate is 100ml / min.

[0046] according to Figure 4 As shown, the cross-linking process conditions for the optimal thermal cross-linking degree lower limit of the thermoplastic polymer polyaryletherketone are: thermal cross-linking temperature is 350 °C, cross-linking heating rate is 3 °C / min, constant temperature time is 30 min, cross-linking atmosphere For air, the air flow rate is 200ml / min.

[0047] Therefore, the optim...

Embodiment 3~11

[0049] The procedure of Example 2 was repeated for the thermoplastic polymers specified in Table 1 below, where the test results are listed.

[0050] Table 1

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com