A method for testing the content of inorganic functional powder in functional polyester

A testing method and functional powder technology, applied in the direction of weighing by removing certain components, can solve the problems of high thermal weight loss mass residual rate, inability to directly and accurately measure the content of inorganic functional powders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

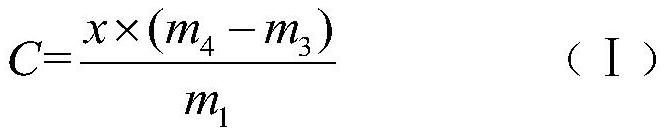

Image

Examples

Embodiment 1

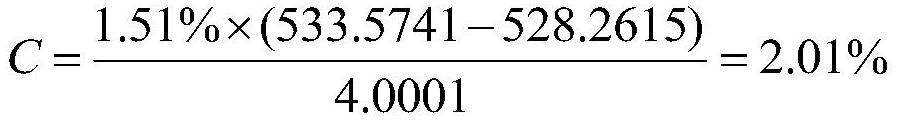

[0060] (1) Dry the polyethylene terephthalate antibacterial fiber sample at a temperature of 130° C. to constant weight to obtain a dried polyethylene terephthalate antibacterial fiber sample;

[0061] (2) take by weighing the polyethylene terephthalate antibacterial fiber sample after the dry treatment of 4.0001g and the methyl alcohol that weight is 24.0003g join in the reaction tube that weight is 528.2615g;

[0062] (3) After the reaction tube is sealed with a sealing device, it is put into a heating device and heated to 330° C. so that the polyethylene terephthalate antibacterial fiber undergoes alcoholysis and depolymerization reaction in methanol reaching a supercritical state, and the reaction time is 30 minutes;

[0063] (4) After the reaction tube is taken out from the heating device and cooled to room temperature, the sealing device of the reaction tube is taken off;

[0064] (5) The reaction tube is placed in a vacuum heating device, and under the conditions of a t...

Embodiment 2

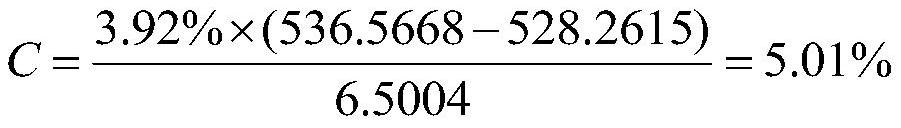

[0071] (1) Dry the polybutylene terephthalate conductive film sample at a temperature of 50° C. to constant weight to obtain a dry polybutylene terephthalate conductive film sample;

[0072] (2) taking by weighing the polybutylene terephthalate conductive film sample after the dry treatment of 6.5004g and the methyl alcohol that weighs 19.5003g joins in the reaction tube that weighs 528.2615g;

[0073] (3) After the reaction tube is sealed with a sealing device, it is put into a heating device and heated to 300° C. so that the polybutylene terephthalate conductive film undergoes alcoholysis and depolymerization reaction in methanol reaching a supercritical state, and the reaction time is 90 minutes;

[0074] (4) After the reaction tube is taken out from the heating device and cooled to room temperature, the sealing device of the reaction tube is taken off;

[0075] (5) The reaction tube is placed in a vacuum heating device, and the methanol that has not participated in the rea...

Embodiment 3

[0082] (1) drying the polytrimethylene terephthalate anti-ultraviolet fiber sample at a temperature of 100° C. to a constant weight to obtain a dried polytrimethylene terephthalate anti-ultraviolet fiber sample;

[0083] (2) Take by weighing the polytrimethylene terephthalate anti-ultraviolet fiber sample after the dry treatment of 1.3001g and the methanol that weighs 26.0003g and join in the reaction tube that weighs 528.2615g;

[0084] (3) After the reaction tube is sealed with a sealing device, it is put into a heating device and heated to 240° C. so that the polytrimethylene terephthalate anti-ultraviolet fiber undergoes an alcoholysis depolymerization reaction in methanol reaching a supercritical state, and the reaction time is 120 minutes;

[0085] (4) After the reaction tube is taken out from the heating device and cooled to room temperature, the sealing device of the reaction tube is taken off;

[0086] (5) The reaction tube is placed in a vacuum heating device, and unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com