Phosphor and nitrogen containing flame retardant curing agent, preparation method and application thereof

A curing agent, phosphorus-nitrogen technology, which is applied in the field of phosphorus-nitrogen-containing flame-retardant curing agent and its preparation, can solve the problems of glass transition temperature of only 72°C and 45°C, and large amount of smoke, and achieve low cost and high production efficiency. Simple, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

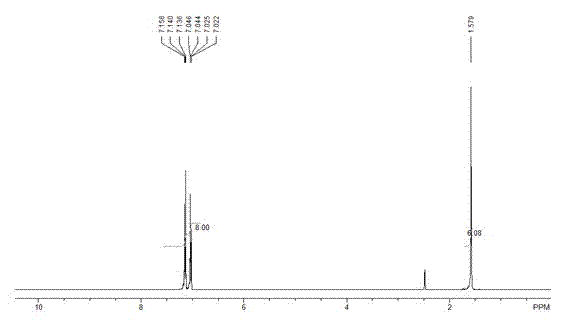

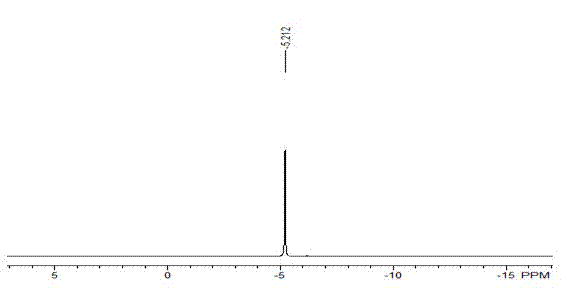

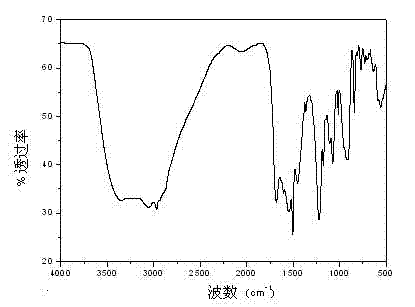

Image

Examples

Embodiment 1

[0026] Add 1 mol of 110 g of hydroquinone A to 2 mol of 180 mL of phosphorus oxychloride. React at 90°C for 5 hours, remove excess phosphorus oxychloride by rotary evaporation under reduced pressure at 85°C, then dissolve in a certain amount of anhydrous acetonitrile, add PEG-600, stir and mix well, add 3.5mol of 200g isocyanic acid in batches Methyl ester, reacted at room temperature for 2 hours, heated to 90-110°C under nitrogen gas, and refluxed for 4 hours. Suction filtration, take the filtrate, and rotary evaporation to obtain a yellow viscous substance intermediate with a yield of 70%.

[0027] The intermediate was added to a certain amount of toluene, and a mixed solution of 10 mol of diamine and toluene was added dropwise under ice-cooling. After 2 hours, the temperature was raised to 70° C., and the reaction was refluxed for 15 hours. A white solid was obtained, which was a phosphorus-nitrogen-containing flame retardant curing agent, and the yield was 90%.

[0028] ...

Embodiment 2

[0033] Add 5 mol of 47 mL of phosphorus oxychloride to 1 mol of 110 g of hydroquinone at 50°C. React at 90°C for 5 hours, remove excess phosphorus oxychloride by rotary evaporation under reduced pressure at 85°C, then dissolve in a certain amount of anhydrous acetonitrile, add PEG-400, stir and mix, add 5mol of 320g isocyanate in batches Ester, react at room temperature for 4h, heat to 70-90°C under nitrogen, and reflux for 6h. Suction filtration, take the filtrate, and rotary evaporation to obtain a yellow viscous substance intermediate with a yield of 75%.

[0034] The intermediate was added to a certain amount of toluene, and a mixed solution of 5 mol of diamine and toluene was added dropwise under ice-cooling. After 2 hours, the temperature was raised to 70° C., and the reaction was refluxed for 15 hours. A white solid was obtained, which was a phosphorus-nitrogen-containing flame retardant curing agent, and the yield was 90%.

[0035]Stir 100 parts by weight of ordinary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com