Method for preparing PVC (Polyvinyl Chloride) heat stabilizing agent by using liquid-state Ca/Zn

A heat stabilizer, liquid technology, applied in the field of preparing PVC heat stabilizer by using liquid Ca/Zn, can solve the problems of poor stabilization efficiency, high price, toxicity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

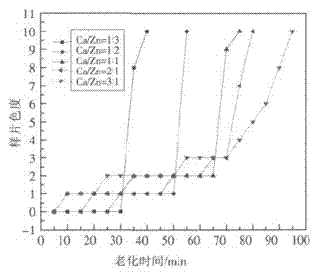

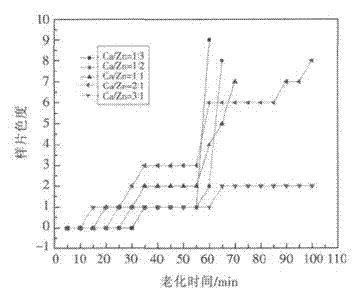

[0024] This example illustrates the influence of the mass ratio of calcium to zinc on the thermal stability of PVC. Under the condition that the amount of organic auxiliary heat stabilizer remains unchanged, the mass ratio of calcium to zinc in the composite stabilizer is changed, and the discoloration time of the Congo red test paper is used to characterize calcium. The effect of zinc mass ratio on the removal of HCl from PVC is shown in Table 1. At the same time, the influence of the mass ratio of calcium to zinc on the static and dynamic aging chromaticity of PVC samples was characterized by the thermal aging oven method and dynamic rolling test. The experimental results are as follows: figure 1 .

[0025] It can be seen from Table 1 that as the mass ratio of Ca / Zn increases, the discoloration time of the Congo red test paper first increases and then decreases, reaching the maximum value of 34.5 min when the ratio is 3:1; figure 1 , figure 2 It can be seen from the figu...

Embodiment 2

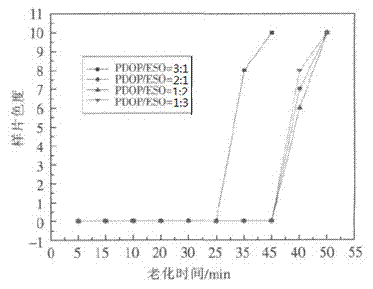

[0029] This embodiment illustrates the impact of PDOP and ESO mass ratio on the thermal stability of PVC. On the premise that PDOP and ESO account for 45% of the total stabilizer, the mass ratio of the two is selected as: 31, 2 / 1, 1 / 2, 1 / 3, discuss the best ratio.

[0030] According to Table 2, as the mass ratio of PDOP and ESO decreases, the discoloration time of Congo red test paper first increases and then decreases. From image 3 , Figure 4 From the static and dynamic aging chromaticity values, it can be seen that with the different mass ratios of the two samples, the initial chromaticity values of the samples are basically the same, but there is a great difference in the later stages. When the mass ratio of the two is 1:2, the color change time of the Congo red test paper is the longest at 37 minutes, and the chromaticity value remains the lowest during the dynamic and static aging process. It shows that when the ratio of the two is 1:2, the synergistic effect is ...

Embodiment 3

[0034] This example illustrates the influence of LDHs on the stability of PVC. The light transmittance of the sample after adding different inorganic materials is measured by using a UV-visible spectrophotometer in the visible light region with a wavelength of 400-800 nm. The results are as follows Figure 5 . From Figure 5 It can be seen from the figure that in the visible light wavelength range, the light transmittance of the PVC sample added with LDHs is the largest, with an average value of 89.3%, followed by the blank sample without adding any inorganic materials, and the third is the addition of 1.0wt.% calcium carbonate The sample with the lowest light transmittance is the sample with titanium dioxide added. It shows that the addition of LDHs can improve the transparency of PVC.

[0035] The experimental results of the influence of LDHs on the thermal stability of PVC are shown in Table 3. It can be seen from Table 3 that the discoloration time of the Congo red test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com