Test method for blast furnace coke reactivity

A test method and technology of blast furnace coke, which are applied in the direction of removing certain components and weighing, etc., to achieve the effect of saving the amount of coke consumed in the test and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below by specific examples.

[0033] Select 6 kinds of cokes used by a certain iron and steel company as test samples, pass through a 200 mesh sieve after being ground, and get the powder under the sieve for subsequent use;

[0034] Put the spare powder in an oven, dry it at 105~120°C for 2 hours, take it out, cool it to room temperature and seal it for later use;

[0035] The test device chooses a microcomputer differential thermal balance manufactured by a company in Beijing;

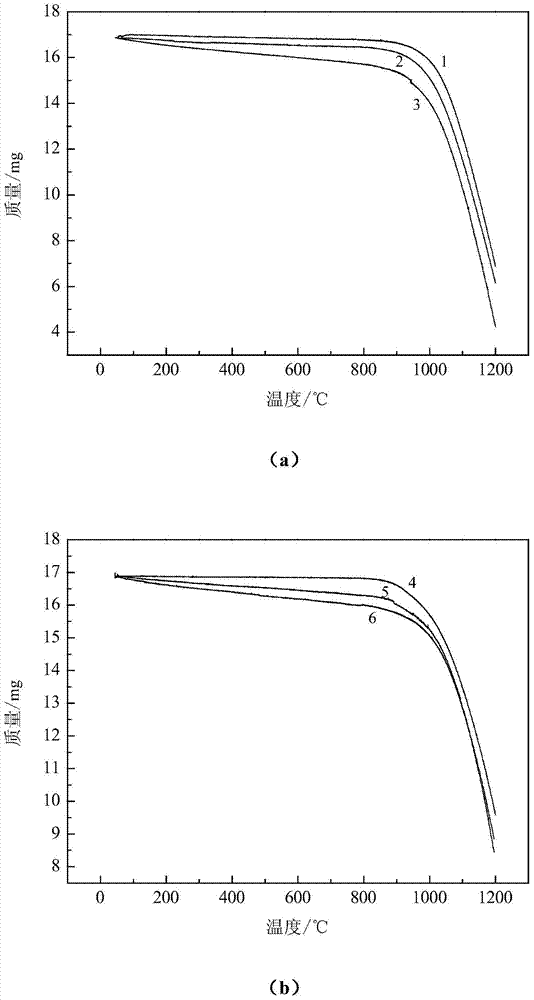

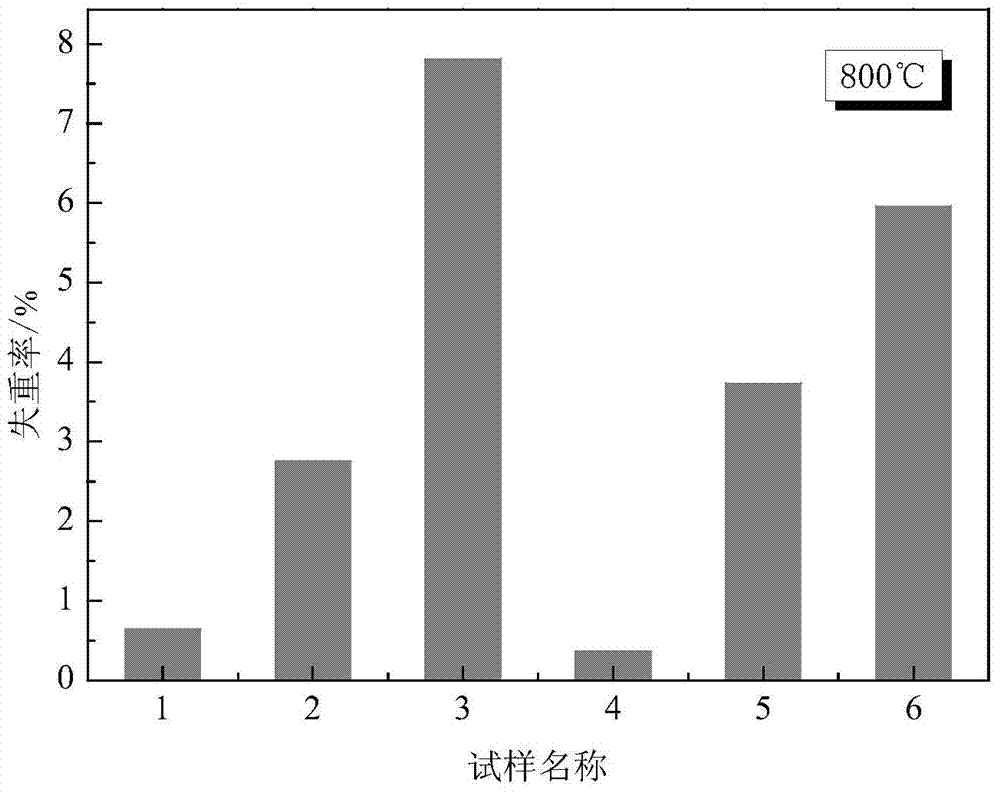

[0036] Weigh 17 mg of each of the 6 spare coke samples, place them in a differential thermal balance in sequence, and continuously raise the temperature at a heating rate of 20°C / min, and at the same time pass the reaction gas CO 2 , the gas flow rate is controlled at 60ml / min;

[0037] The set heating range is from room temperature to 1200°C;

[0038] After reaching the heating end point, the computer data collection is completed, and the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com