A method for evaluating the quality stability of finished cigarettes between batches

A technology for quality stability and finished cigarettes, applied in the direction of removing a certain component and weighing, etc., can solve the problems of high requirements for instruments and equipment, complicated operation, complicated detection and data processing, etc., to achieve objective experimental results, equipment and operation. Simple handling and small sample size results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

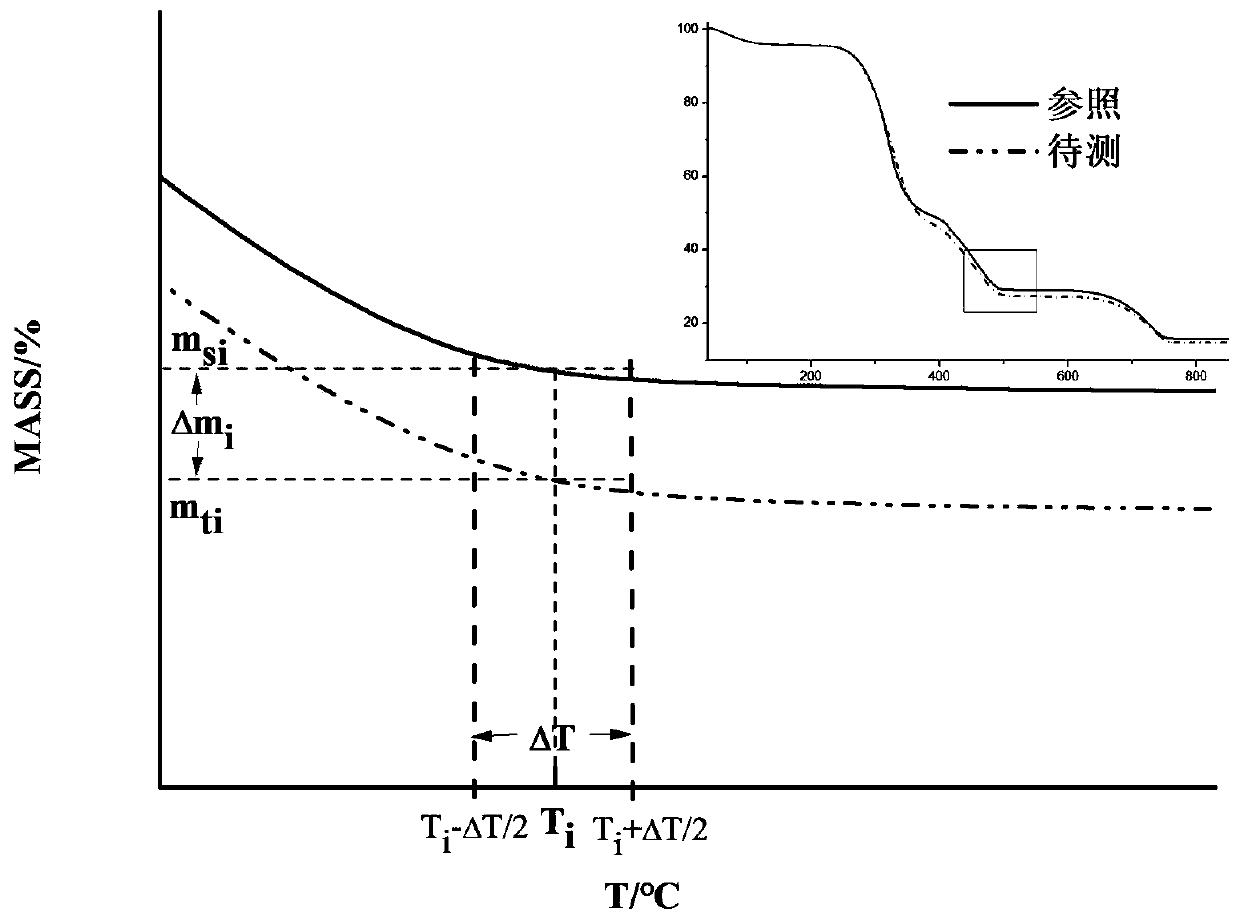

Method used

Image

Examples

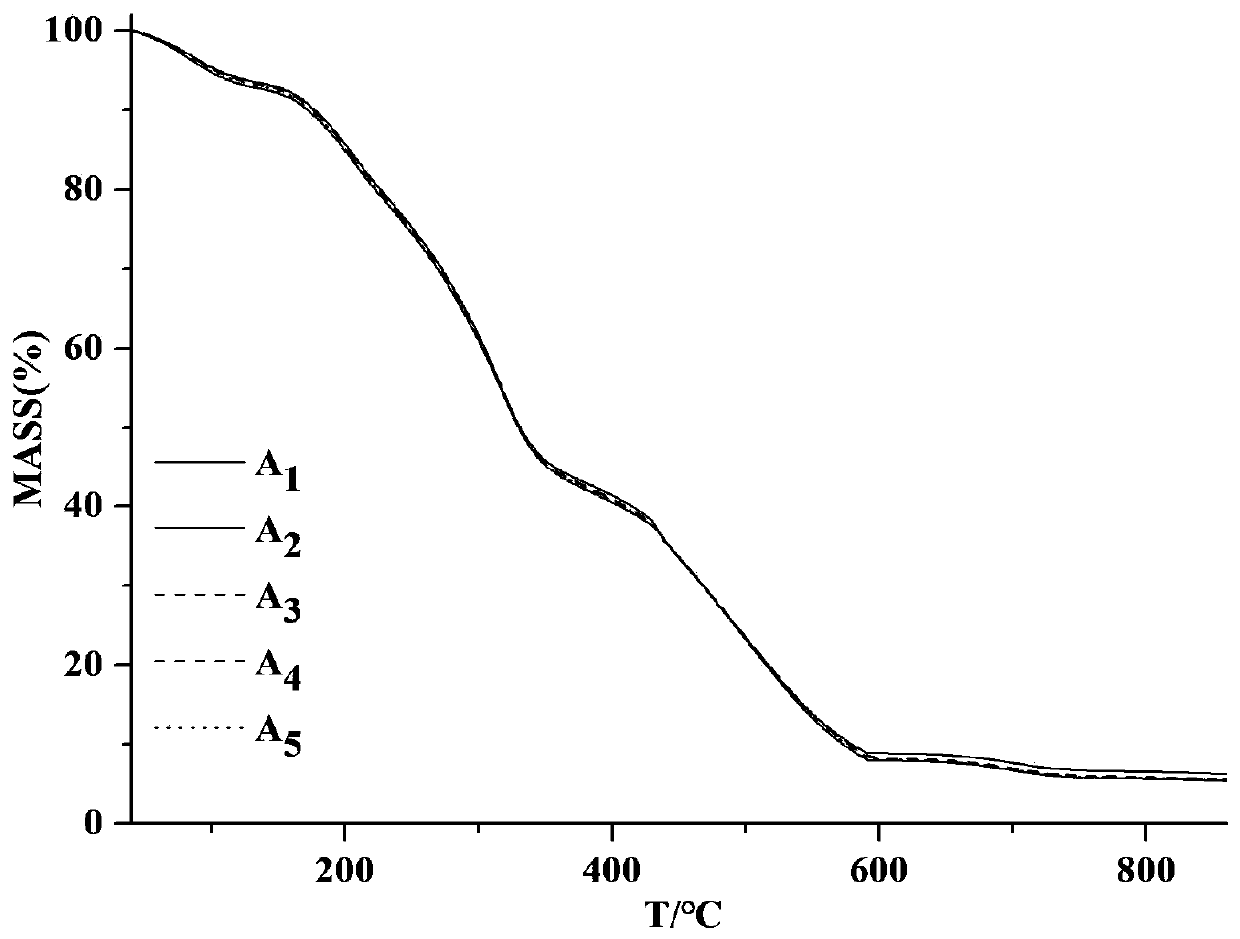

Embodiment 1

[0043] Embodiment 1. In this embodiment, the quality stability of batch B cigarette samples of the same brand specification is compared with the finished cigarettes of batch A of a certain brand specification as a reference. The specific operation includes the following steps:

[0044] (1) Sampling and pretreatment of finished cigarette samples

[0045]Batch A finished cigarettes were randomly selected 5 times, and Batch B finished cigarettes were randomly selected 2 times, and 2 boxes were randomly selected each time, each time as a sample. Open the small box packaging of each sample, peel off the cigarette paper and filter, take out the shredded tobacco in the cigarette, mix it evenly and place it in a constant temperature and humidity room with a temperature of (22±1)°C and a relative humidity of (60±2)%. Environment equilibrated for 48 hours standby.

[0046] (2) Thermogravimetric analysis of finished cigarette samples

[0047] Grind each balanced cigarette sample throu...

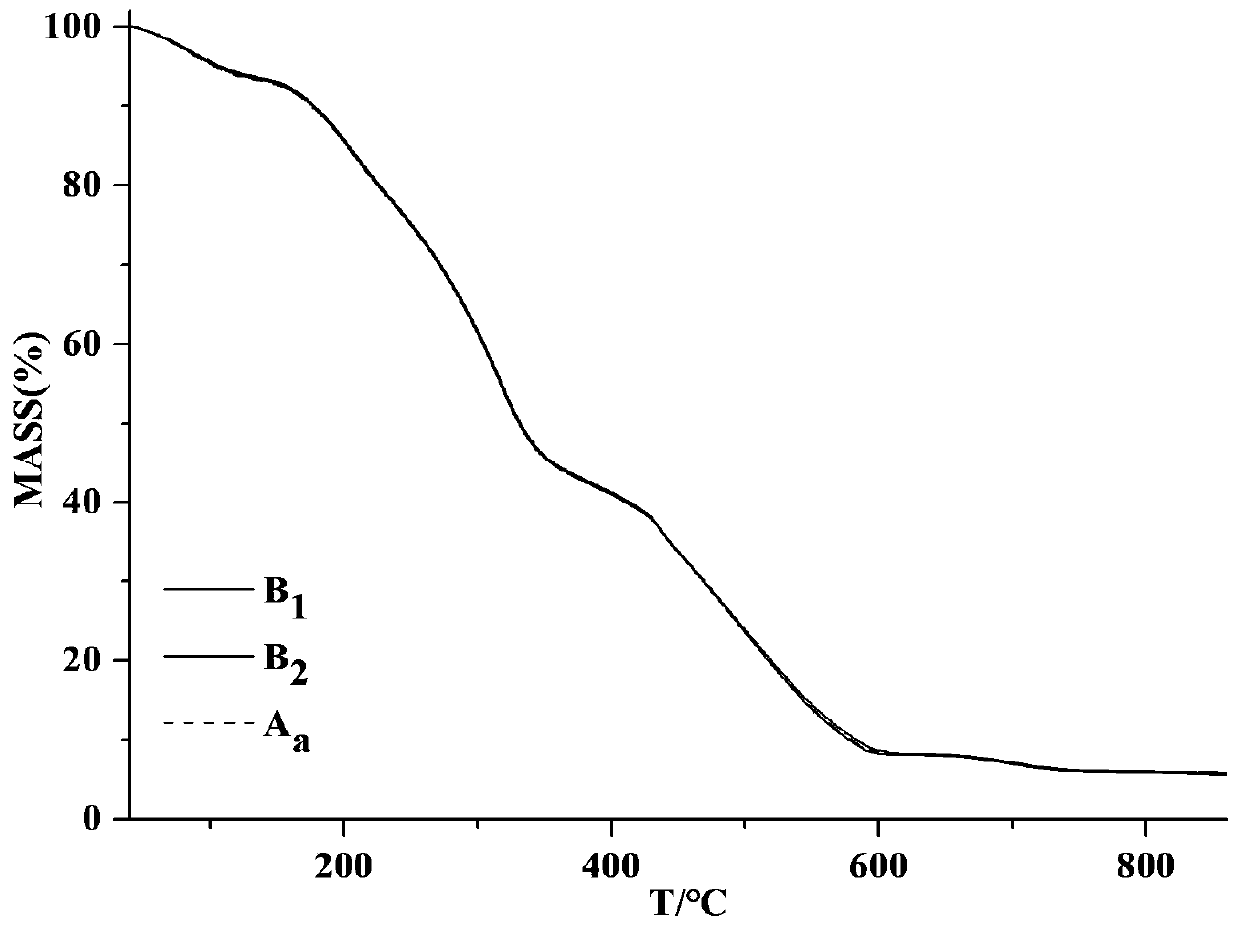

Embodiment 2

[0068] Example 2. In this example, the quality stability of the batch C cigarette samples of the same brand specification was compared with the finished cigarettes of batch A of a certain brand specification as a reference. The specific operation includes the following steps:

[0069] (1) Sampling and pretreatment of finished cigarette samples

[0070] Batch A finished cigarettes were randomly selected 5 times, and Batch C finished cigarettes were randomly selected 2 times, and 2 boxes were randomly selected each time, each time as a sample. Open the small box packaging of each sample, peel off the cigarette paper and filter, take out the shredded tobacco in the cigarette, mix it evenly and place it in a constant temperature and humidity room with a temperature of (22±1)°C and a relative humidity of (60±2)%. Environment equilibrated for 48 hours standby.

[0071] (2) Thermogravimetric analysis of finished cigarette samples

[0072] Grind each balanced cigarette sample throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com