A Method for Evaluating the Quality Stability of Reconstituted Tobacco Leaf Between Batches

A quality stability and reconstituted tobacco leaf technology, applied in the direction of weighing by removing certain components, can solve the problems of heavy detection workload, a large number of instruments and reagents, and complex data processing in the later stage, so as to achieve small sample volume and high experimental results. Objective, simple equipment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

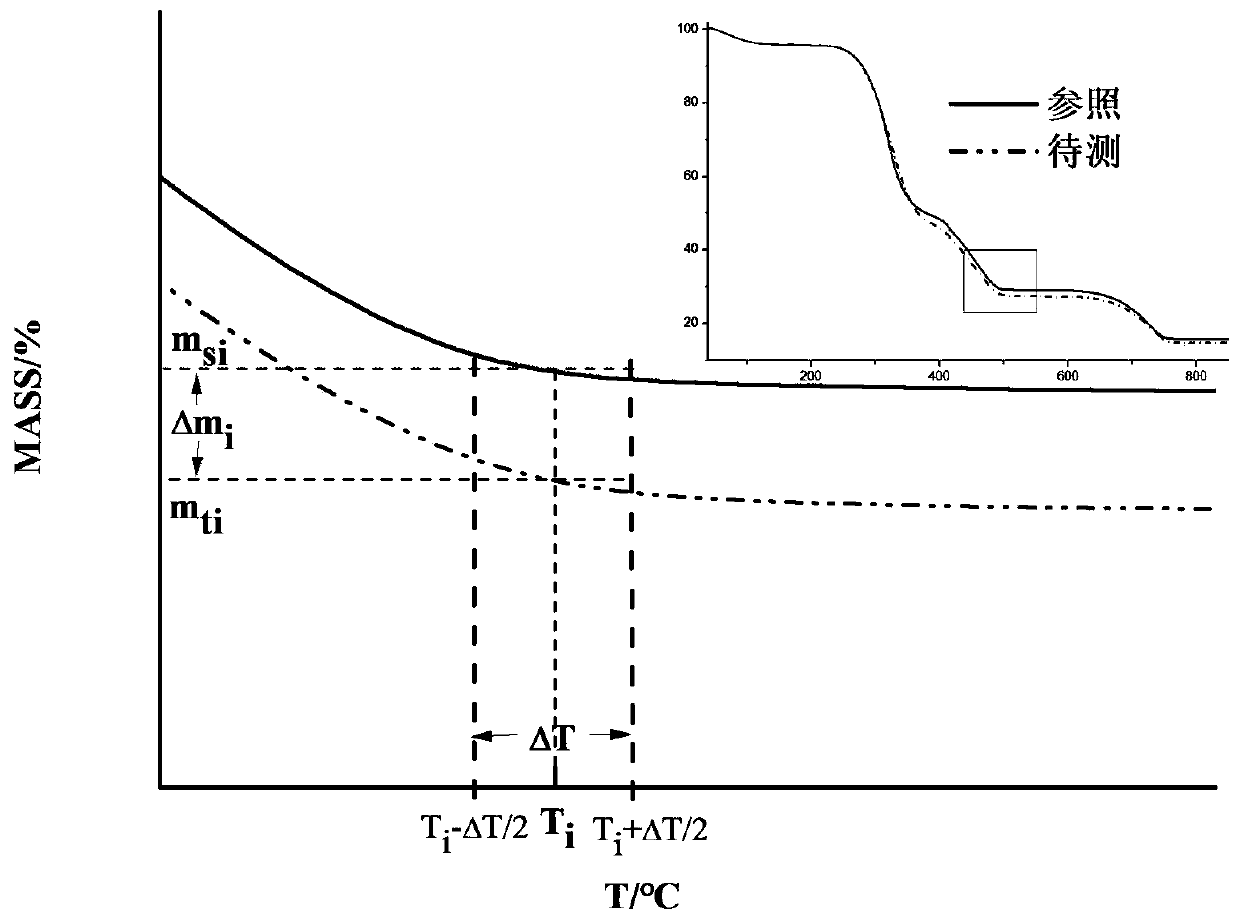

Method used

Image

Examples

Embodiment 1

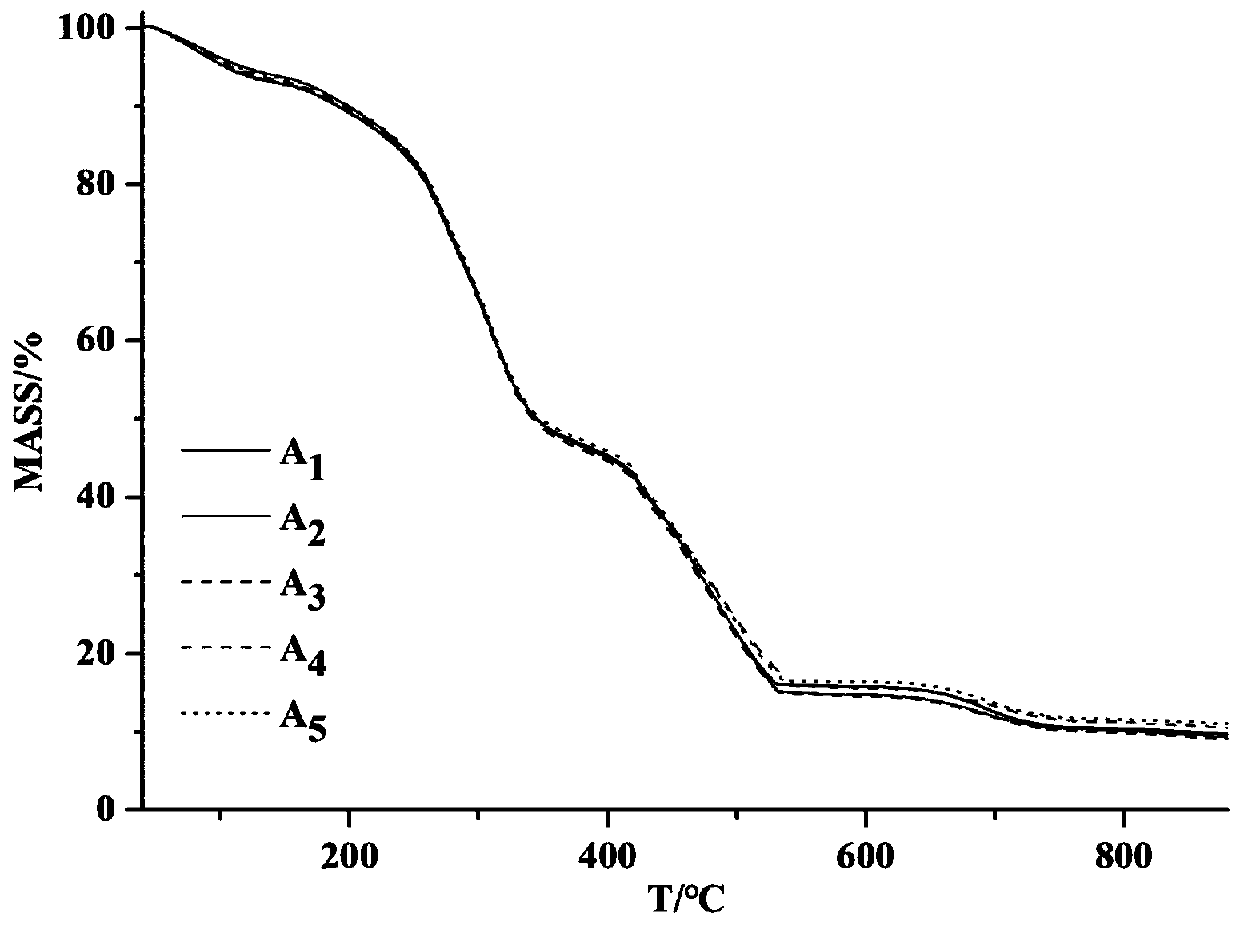

[0042] Example 1. In this example, the quality stability of batch B reconstituted tobacco samples of the same brand specification was compared with batch A reconstituted tobacco leaves of a certain brand specification as a reference. The specific operation includes the following steps:

[0043](1) Sampling and pretreatment of reconstituted tobacco samples

[0044] The reconstituted tobacco leaves of Batch A were randomly drawn 5 times, and the reconstituted tobacco leaves of Batch B were randomly drawn 2 times, 10 g were randomly drawn each time, each time as a sample. Place each sample in a constant temperature and humidity environment at (22±1)°C and a relative humidity of (60±2)% for 48 hours for standby;

[0045] (2) Thermogravimetric analysis of reconstituted tobacco samples

[0046] Grind each balanced reconstituted tobacco leaf sample through a 40-mesh sieve, weigh (10 ± 1) mg, place it in an alumina crucible of a thermogravimetric analyzer, and perform a thermal anal...

Embodiment 2

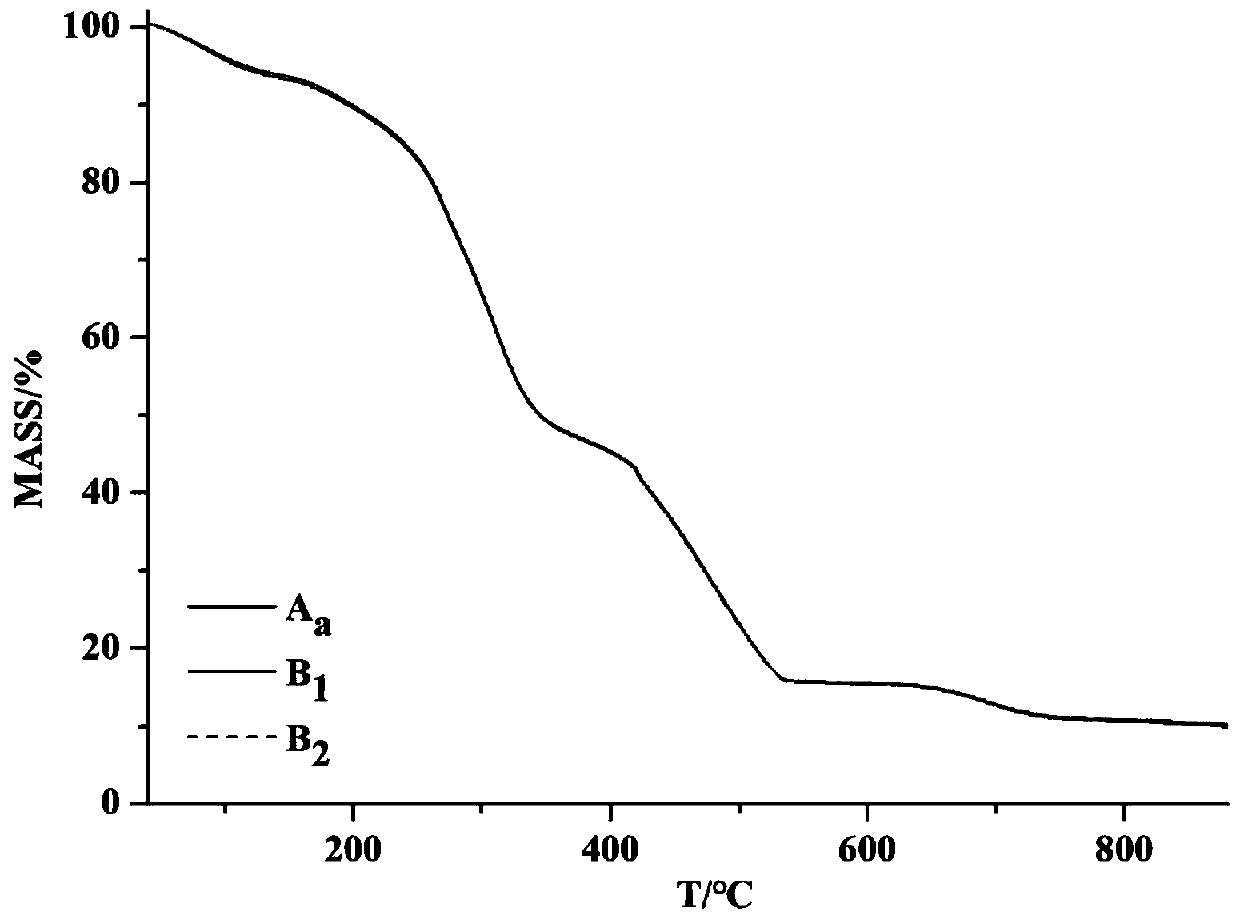

[0062] Example 2. In this example, the quality stability of batch C reconstituted tobacco samples of the same brand specification was compared with batch A reconstituted tobacco leaves of a certain brand specification as a reference. The specific operation includes the following steps:

[0063] (1) Sampling and pretreatment of reconstituted tobacco samples

[0064] The reconstituted tobacco leaves of Batch A were randomly drawn 5 times, and the reconstituted tobacco leaves of Batch C were randomly drawn 2 times, 10 g were randomly drawn each time, each time as a sample. Place each sample in a constant temperature and humidity environment at (22±1)°C and a relative humidity of (60±2)% for 48 hours for standby;

[0065] (2) Thermogravimetric analysis of reconstituted tobacco samples

[0066] Grind each balanced reconstituted tobacco leaf sample through a 40-mesh sieve, weigh (10 ± 1) mg, place it in an alumina crucible of a thermogravimetric analyzer, and perform a thermal ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com