Method for cleaning coal powder at sealing section of gas extraction drill hole

A technology of gas drainage and sealing section, which is applied in the field of cleaning residual coal powder in boreholes, can solve the problems of endangering the health of coal miners, poor cleaning effect of coal powder, and polluting the working environment, so as to improve the effect of gas drainage and widely Practicality and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below.

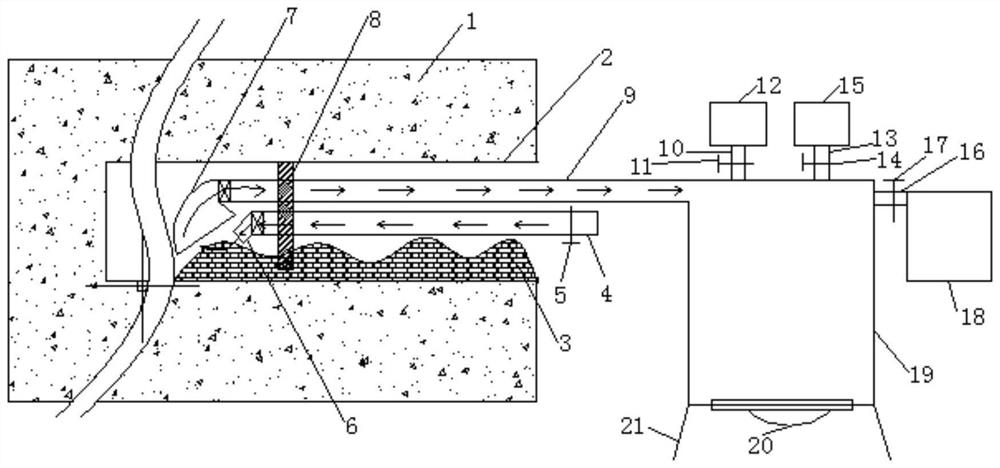

[0017] Such as figure 1 Shown, concrete steps of the present invention are:

[0018] A. Install the device for cleaning the residual pulverized coal in the gas drainage drilling hole sealing section to the gas drainage drilling that needs to be cleaned, and connect one end of the gas injection pipe 4 to the underground compressed air system of the coal mine;

[0019] B. Open the fourth control valve 17, the centrifugal fan 18, the second control valve 11, the water mist generator 12, the third control valve 14 and the liquid nitrogen mist generator 15 in order, and the centrifugal fan 18 works to make the coal Negative pressure is generated in the powder storage tank and the suction pipe 9, and then the air in the sealed area enters the pulverized coal storage tank 19 through the suction pipe inlet 7; The water mist spray pipe transports the fine water mist into the pulverized coal storage tank 19, and the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com