Yarn bobbin automatic cleaning and recycling equipment

A technology for automatic cleaning and recycling equipment, applied in cleaning methods and utensils, cleaning methods using tools, textiles and papermaking, etc., can solve the problems affecting the recycling of yarn tubes, yarn residues in yarn tubes, and increasing economic costs. , to achieve the effect of quick and efficient cleaning, efficient production, and increased versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

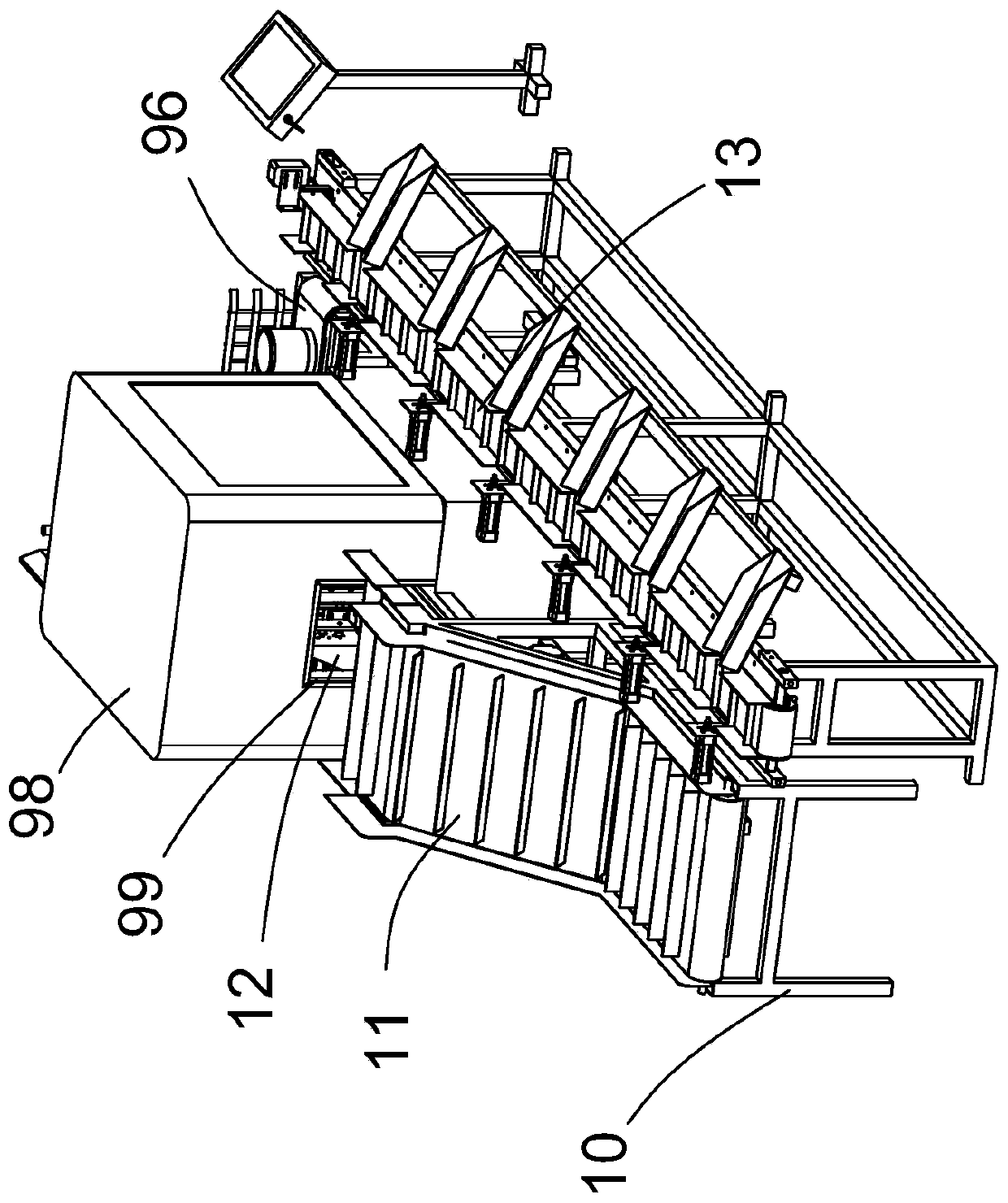

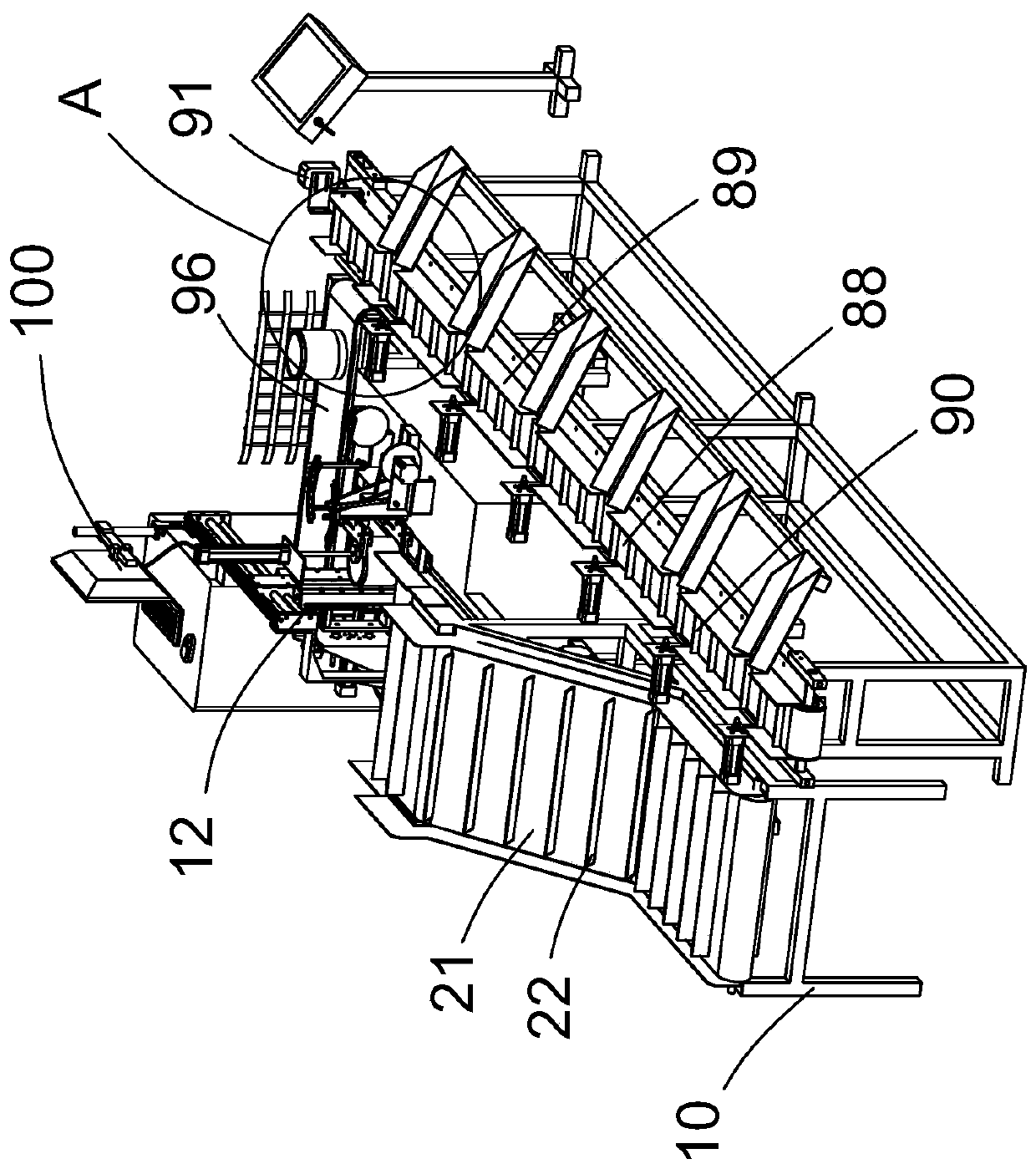

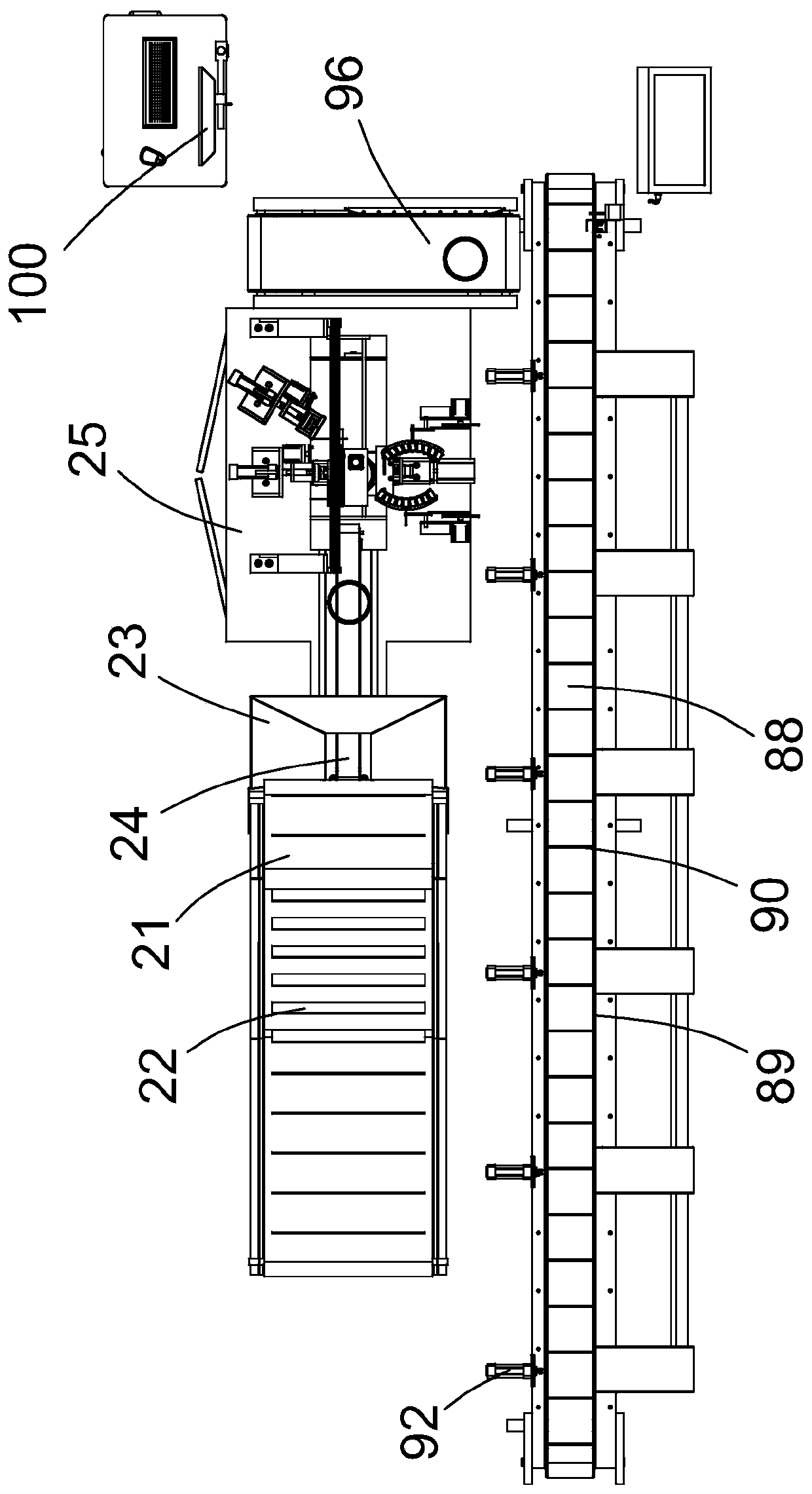

[0045] refer to Figure 1 to Figure 18 , the embodiment of the present invention discloses automatic cleaning and recycling equipment for yarn bobbins, including a frame 10, on which a feeding mechanism 11 for conveying the yarn bobbins to be cleaned is sequentially arranged on the frame 10 according to assembly line processing, for A cleaning mechanism 12 for cleaning the yarn bobbins, and a sorting mechanism 13 for sorting and recovering the cleaned yarn bobbins.

[0046] The feeding mechanism 11 includes a second conveyor belt 21 for conveying the yarn bobbin, the second conveyor belt 21 is arranged on the frame 10, and the frame 10 is provided with a device for driving the second conveyor belt. A number of second conveyor rollers driven by the conveyor belt 21, the second conveyor belt 21 is wound on the second conveyor roller, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com