Combustion furnace for total organic carbon determination

A technology of total organic carbon and combustion furnace, applied in the field of combustion furnace, can solve the problems of incomplete oxidation, inability to precisely control the internal temperature of the combustion furnace, etc., and achieve the effect of preventing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

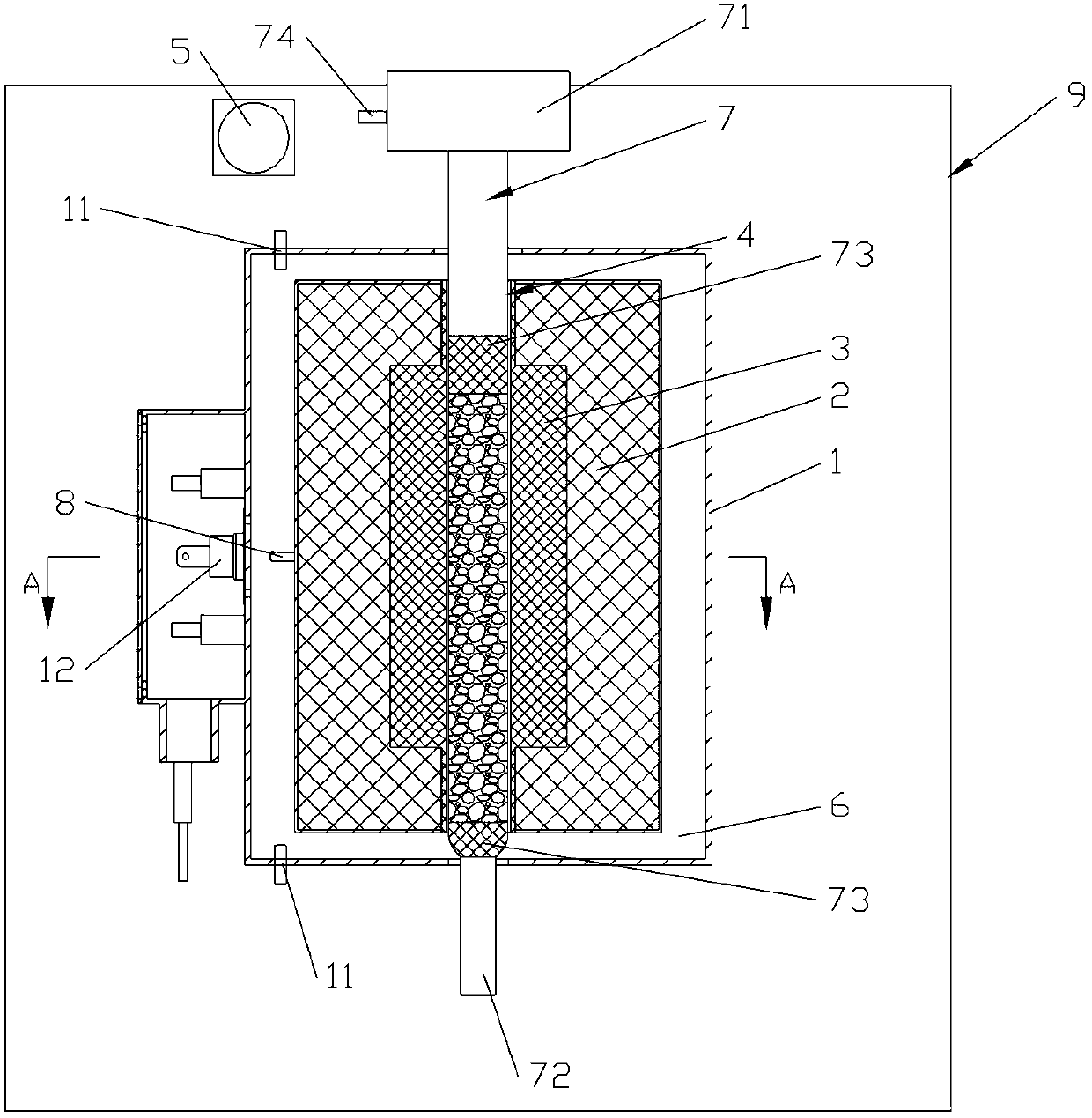

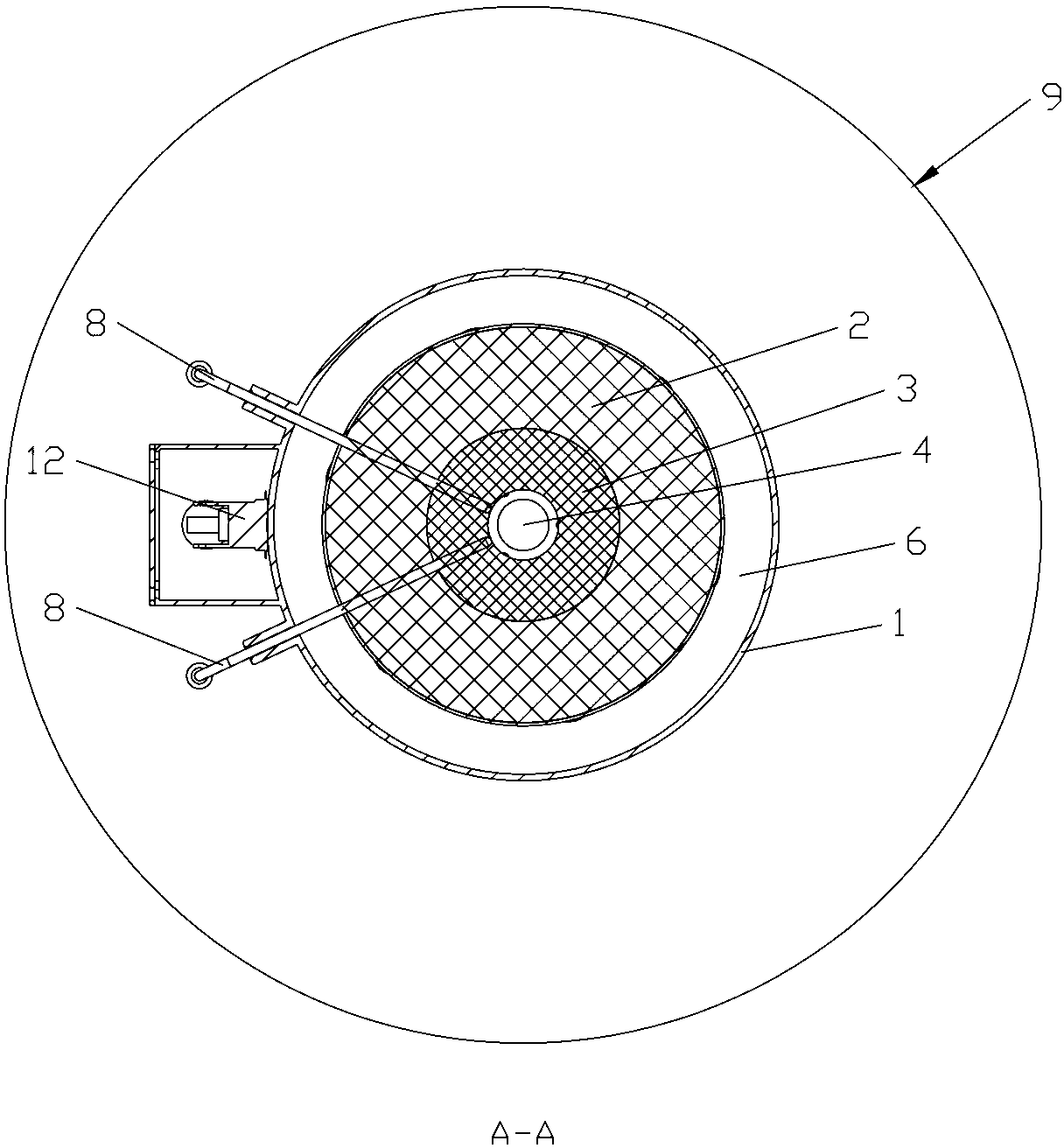

[0028] Combustion furnaces for the determination of total organic carbon, such as figure 1 , 2 As shown, it includes an insulating layer 1, an insulating layer 2 inside the insulating layer 1, a heating device 3 inside the insulating layer 2, a furnace core through hole 4, and a heat-conducting fan 5; the insulating layer 1 is located in a closed combustion chamber. Inside the furnace chamber 9 , an air outlet is provided above the side wall of the combustion furnace chamber 9 , a heat conduction fan 5 is provided on the air outlet, and an air inlet is provided at the bottom of the combustion furnace chamber 9 .

[0029] The upper and lower ends of the partition shell 1 are respectively provided with ventilation holes 11 . An air spacer 6 for air flow is formed between the insulation layer 2 and the spacer shell 1. In order to ensure the insulation effect of the air spacer 6, the minimum gap of the air spacer 6 should be ≥ 1cm, and the material of the insulation layer 2 is H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com