Wood japanning apparatus for uniform japanning

A uniform and wood-based technology, which is applied in the field of wood painting, can solve the problems of easy overlap of painting, affect the quality of painting, and uneven thickness of painting, so as to achieve the effect of uniform painting, uniform dipping and avoiding easy overlapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

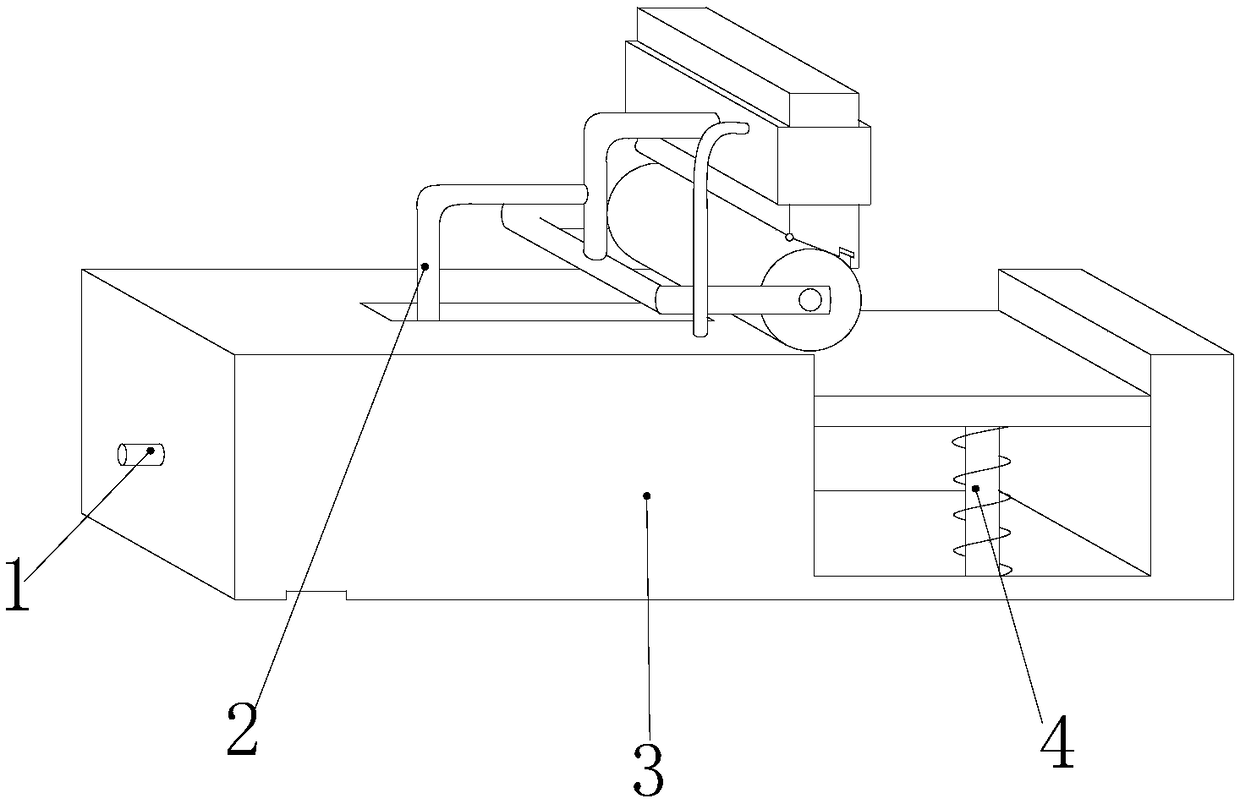

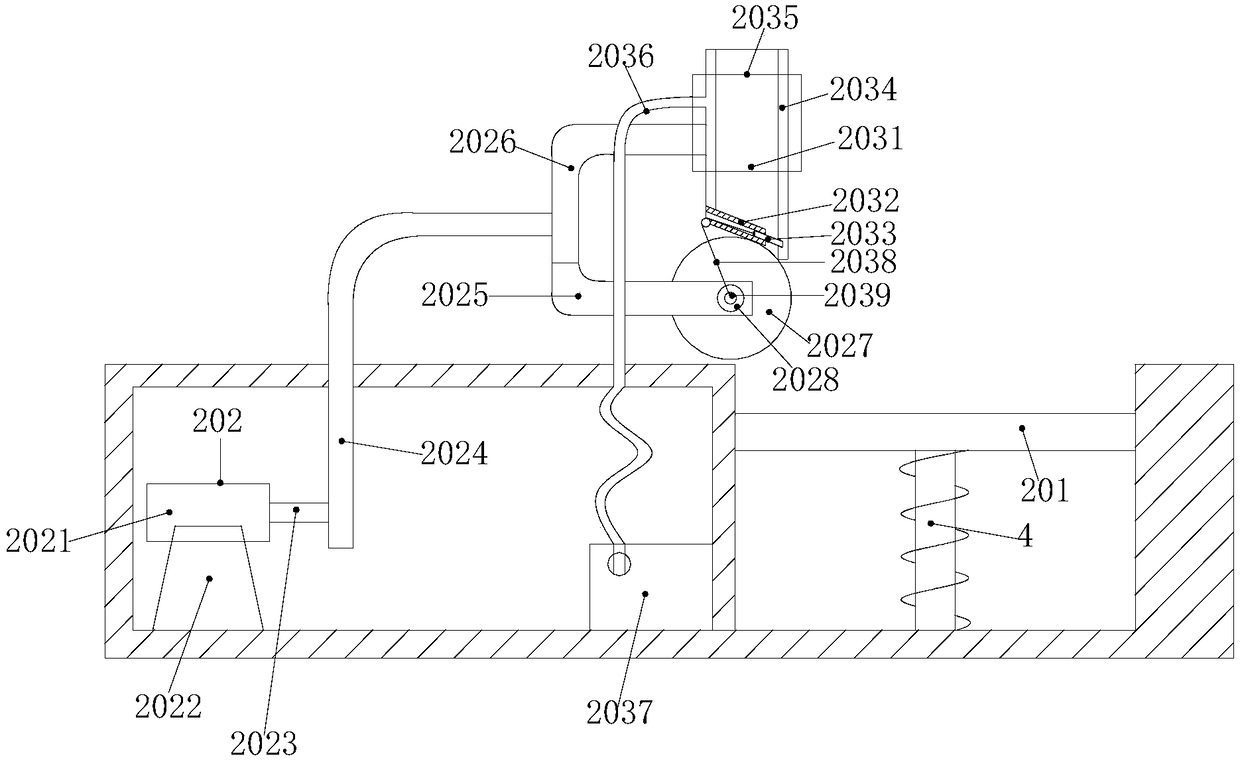

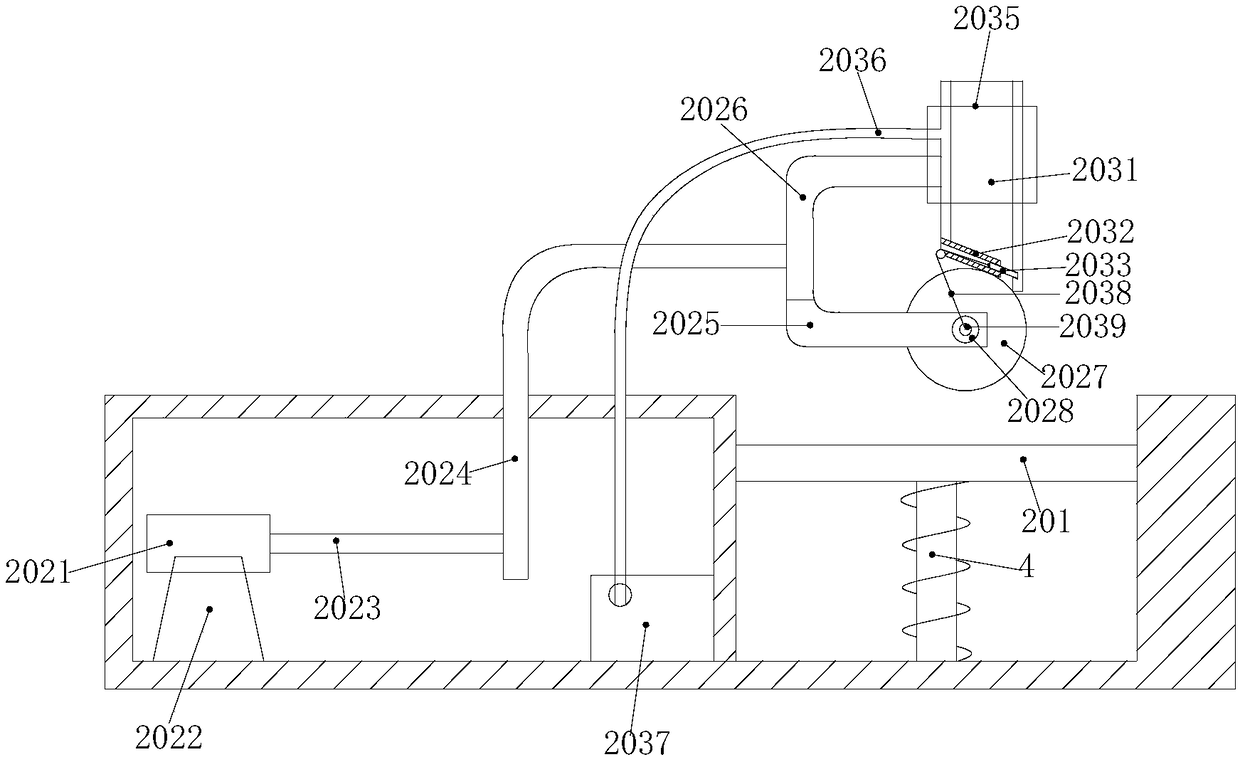

[0025] see Figure 1-Figure 7 , the present invention provides a kind of evenly painted wood painting device, its structure comprises air pressure conveying pipe 1, uniform painting mechanism 2, shell 3, threaded rod 4, and described air pressure conveying pipe 1 is arranged on shell 3 and will The casing 3 runs through, the uniform painting mechanism 2 is installed in the casing 3, the uniform painting mechanism 2 communicates with the pneumatic conveying pipeline 1, and the threaded rod 4 and the pneumatic conveying pipeline 1 are respectively arranged on the casing 3 On opposite sides, the threaded rod 4 is connected with the housing 3 .

[0026] Described uniform painting mechanism 2 is made of timber placing platform 201, painting mechanism 202, paint-dipping mechanism 203, and described timber placing platform 201 and threaded rod 4 are vertically established and are installed on threaded rod 4 tops, and described The wood placing platform 201 cooperates with the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com