Turnover case and fixed angle connector

A technology of corner connectors and turnover boxes, which is applied in the direction of connection components, thin plate connections, external accessories, etc., can solve the problems of easily damaged joints, troubles, and time-consuming disassembly of turnover boxes, so as to achieve local damage, reduce costs, and facilitate placement and the effect of forklift handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

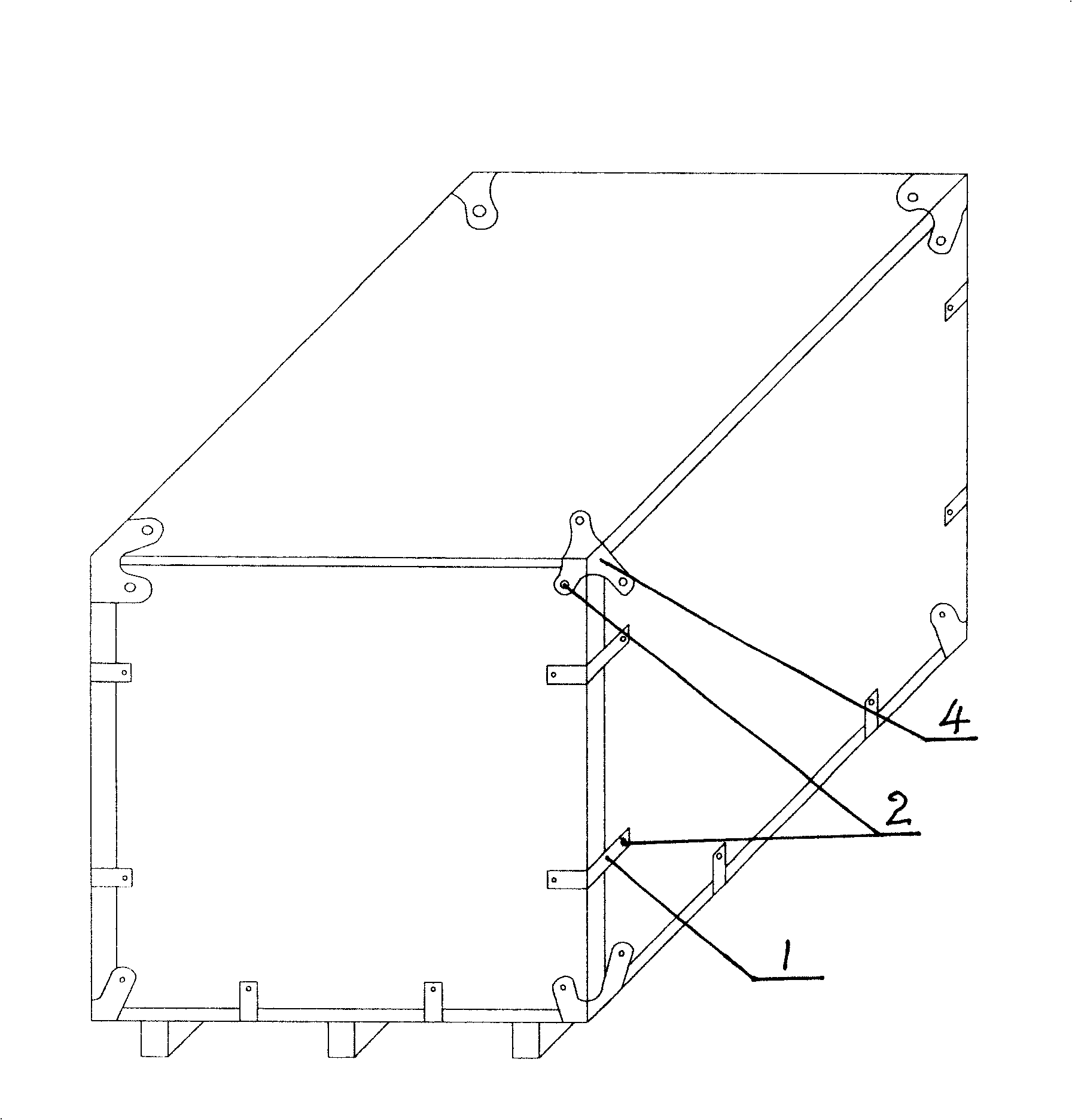

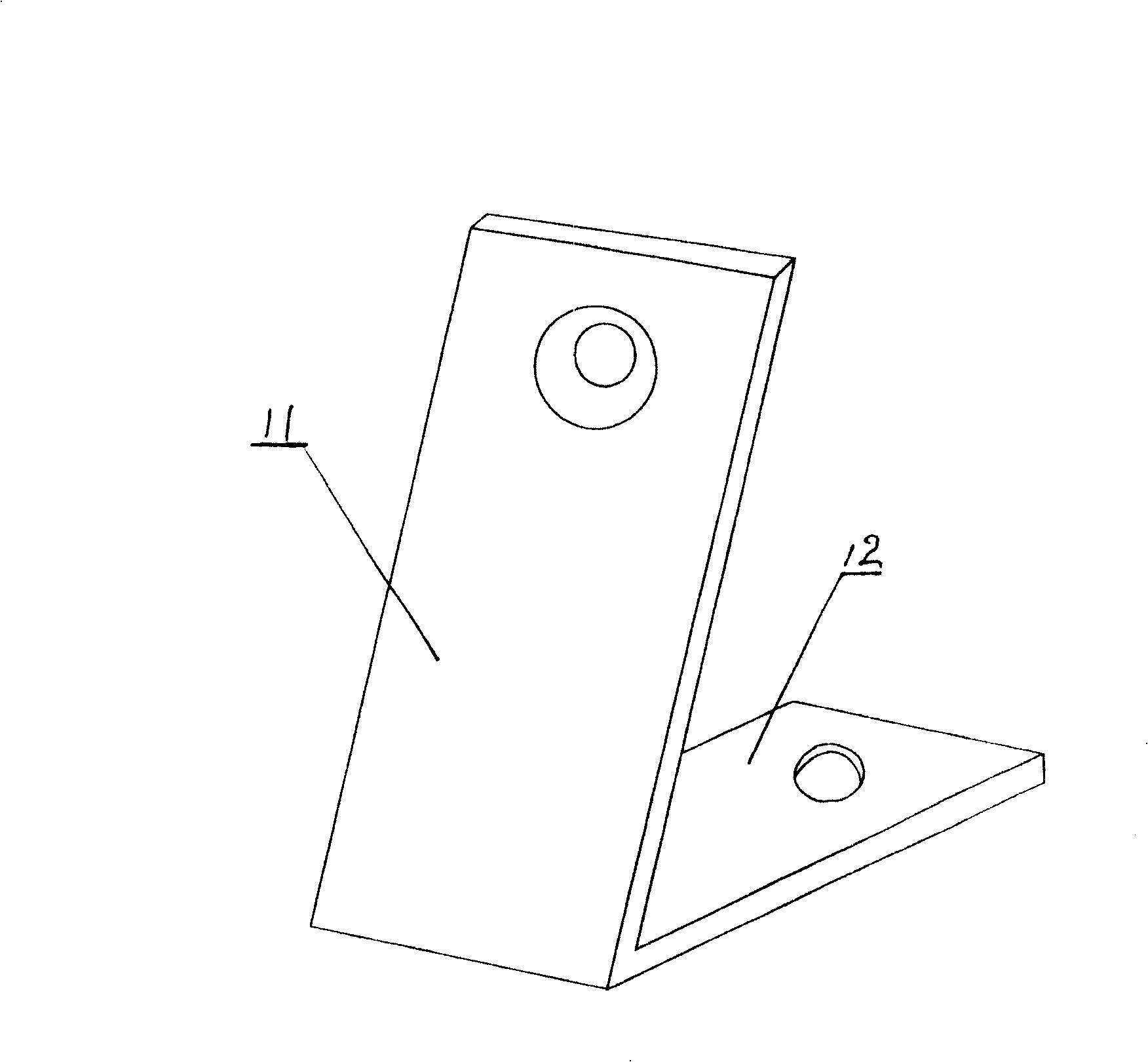

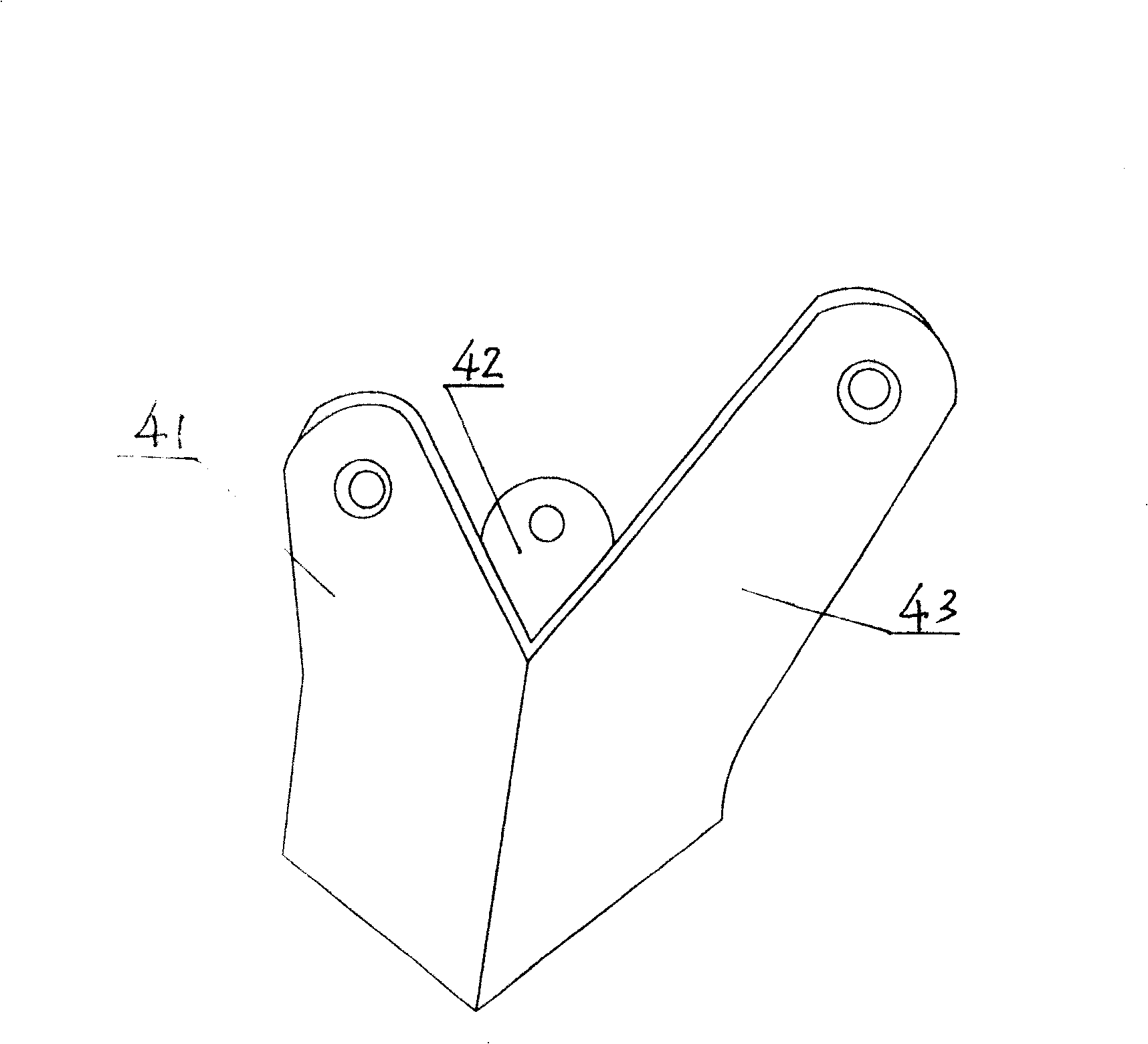

[0009] Embodiment 1, a rectangular turnover box and fixed angle connectors of the present invention, see figure 2 , 5 , 6, by base plate F, four side plates A, B around, the wooden box board of six multi-layer gluings such as top cover plate E forms casing. Wooden pole 5 is connected below the base plate. Adjacent wooden box boards are perpendicular to each other and the edge of one wooden box board overlaps with the end face of the other wooden box board; all corners of the box body are covered with fixed angle connectors 1, and each edge of the bottom corner and side corner The corner distribution covers three fixed-angle connectors, and each corner distribution of the upper corner covers two fixed-angle connectors. Connection holes 2 are opened at both ends of each fixed-angle connector and corresponding wooden box board positions. see Figure 5 , the connecting hole 3 of the box plate is connected with a claw nut (abbreviated as four-claw nut) 6 with four claws. The d...

Embodiment 2

[0010] Embodiment 2, a kind of turnover box of the present invention and fixed angle connector, are made of base (bottom plate and wooden pole below), four side plates around, top cover plate such six blockboard wooden box boards Form the box. There is a wooden shoulder under the bottom plate, and a connecting hole is opened at the corresponding position of the bottom plate and the wooden shoulder. The inner end of the connecting hole on the bottom plate is inserted with a nut with claws. The base of the box. The adjacent wooden box boards are perpendicular to each other and the edge of one wooden box board overlaps with the end face of the other wooden box board; the bottom corner and side corner of the box body are covered with Shaped connecting plate fixed angle connector 1, each corner of the bottom corner and side corner is distributed to cover two Shaped connecting plate and fixed angle connectors, each There are connecting holes 2 at the two ends of the fixed-angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com