Lacquering method and lacquering device of enameling machine

The technology of a painting device and enamelling machine, which is applied in the field of enameled wire manufacturing, can solve problems such as the inability to composite paint on aluminum wires, the performance degradation of enameled wires, and the inability to apply multiple layers of different paints at the same time, so as to achieve the effect of improving production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

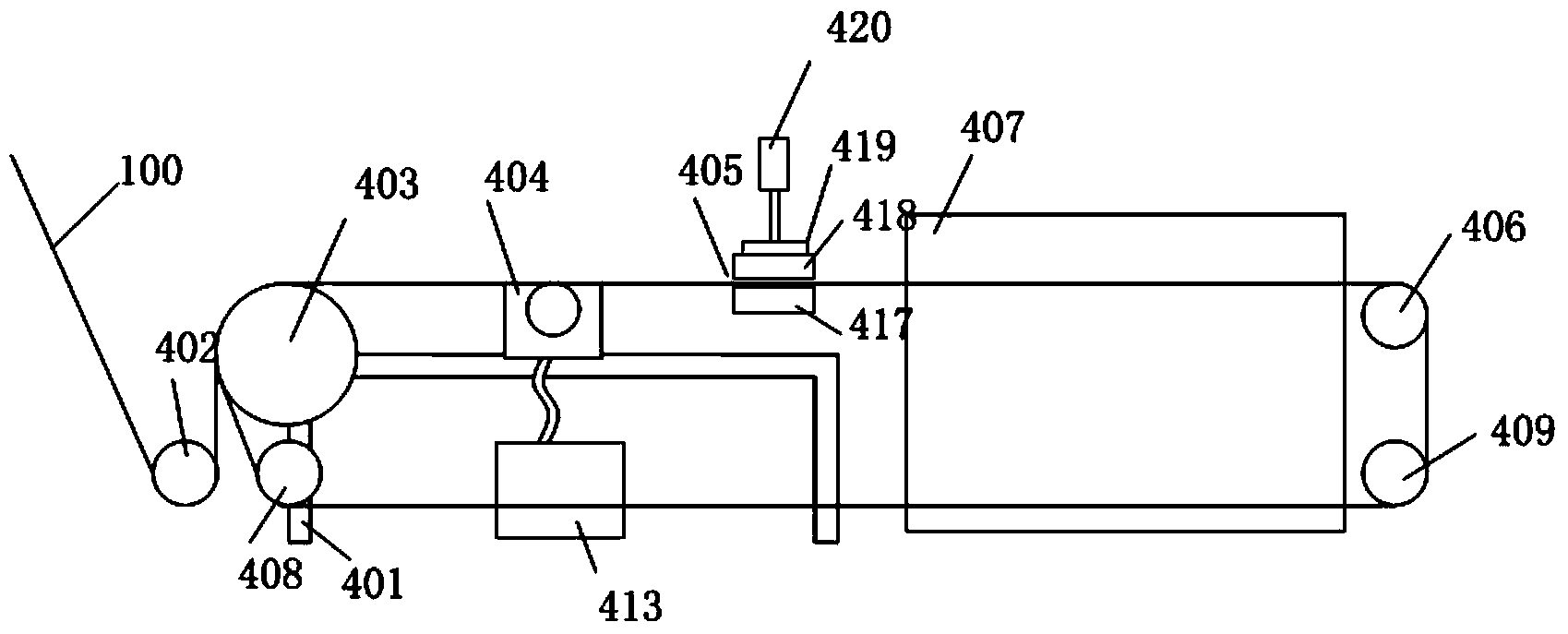

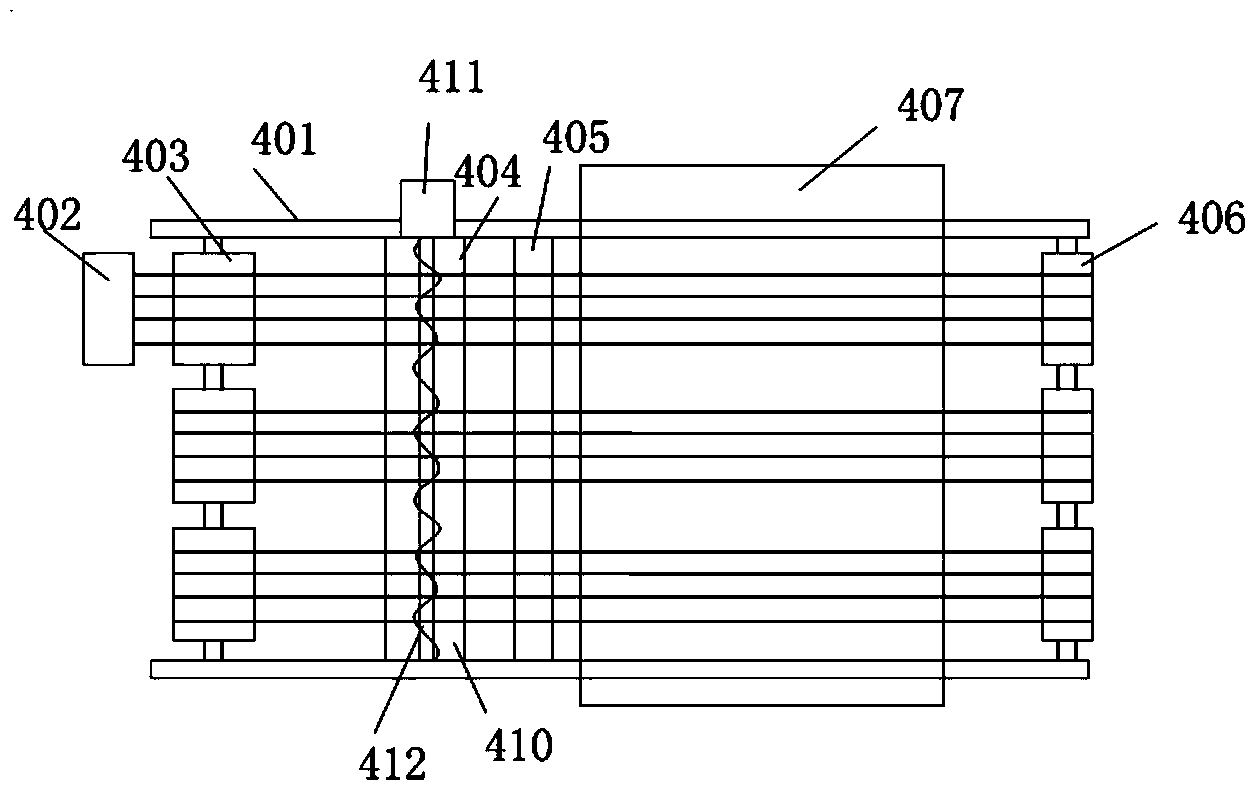

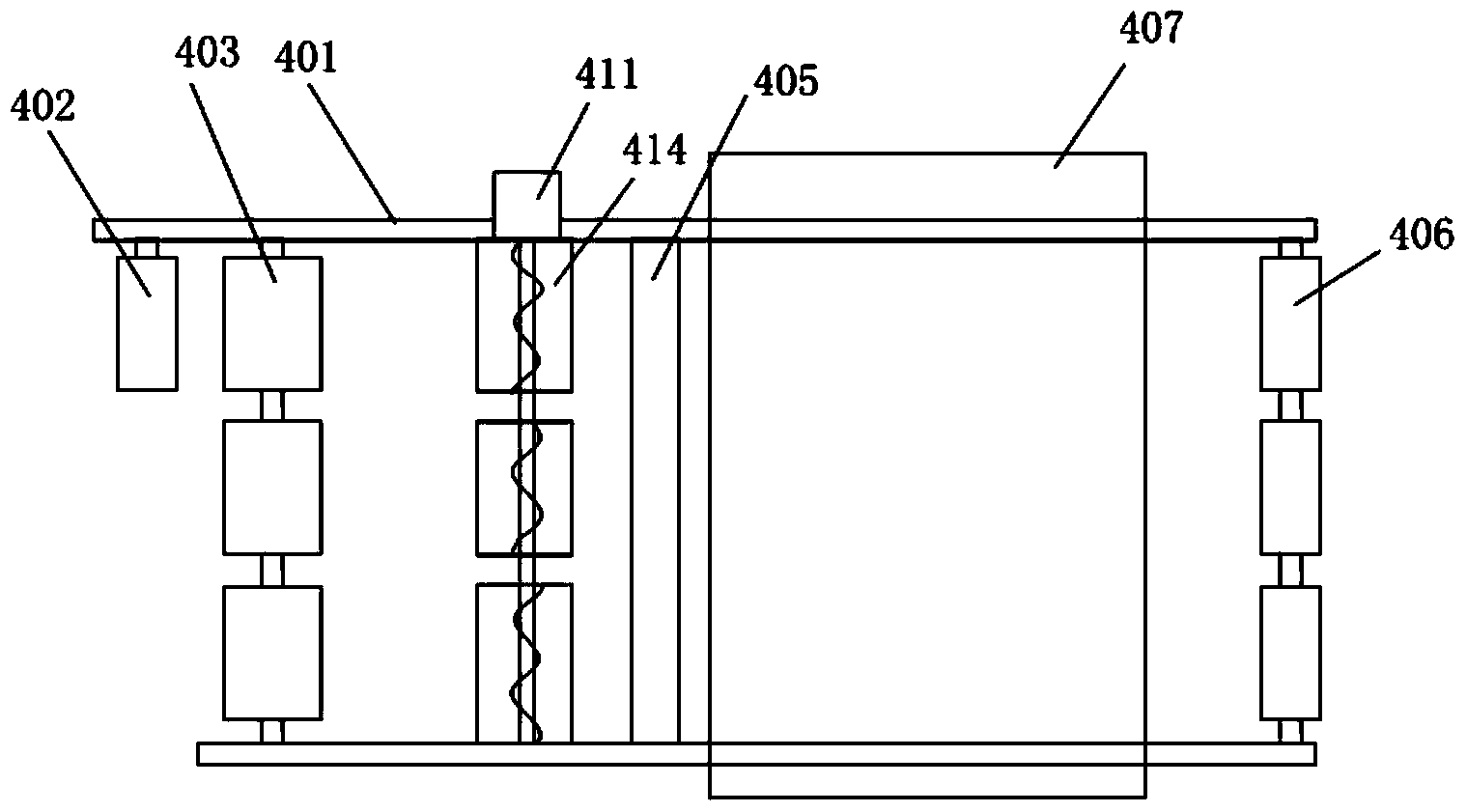

[0018] Embodiment: A painting method for an enamelled machine, which repeatedly paints and dries the annealed aluminum wire, realizes the number of times and layers of paint for the enameled wire, and realizes the function of multi-pass painting at the same time for one machine . Realize the painting device of the enamelling machine of this method, as attached figure 1 and figure 2 As shown, including a frame 401, the front of the frame 401 is provided with a guide wheel 402, and the upper left of the frame 401 is provided with more than 2 groups of left upper roller groups 403 arranged in horizontal rows. Layers, the back of the upper left roller group 403 is provided with a painting mechanism 404, a felt layer 405 and an upper right roller group 406, the number of the upper right roller group 406 is consistent with the upper left roller group, and the felt layer 405 described in the upper right roller group is the same as that of the upper right roller group An oven 407 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com