Varnish interruption alarm method and varnish interruption alarm mechanism for enameling machine

An enameling machine and paint breaking technology, applied in the field of integrated systems, can solve the problems of applying multiple different paints at the same time, burning the oil pump, restricting the painting effect, etc., and achieving the effect of preventing paint spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

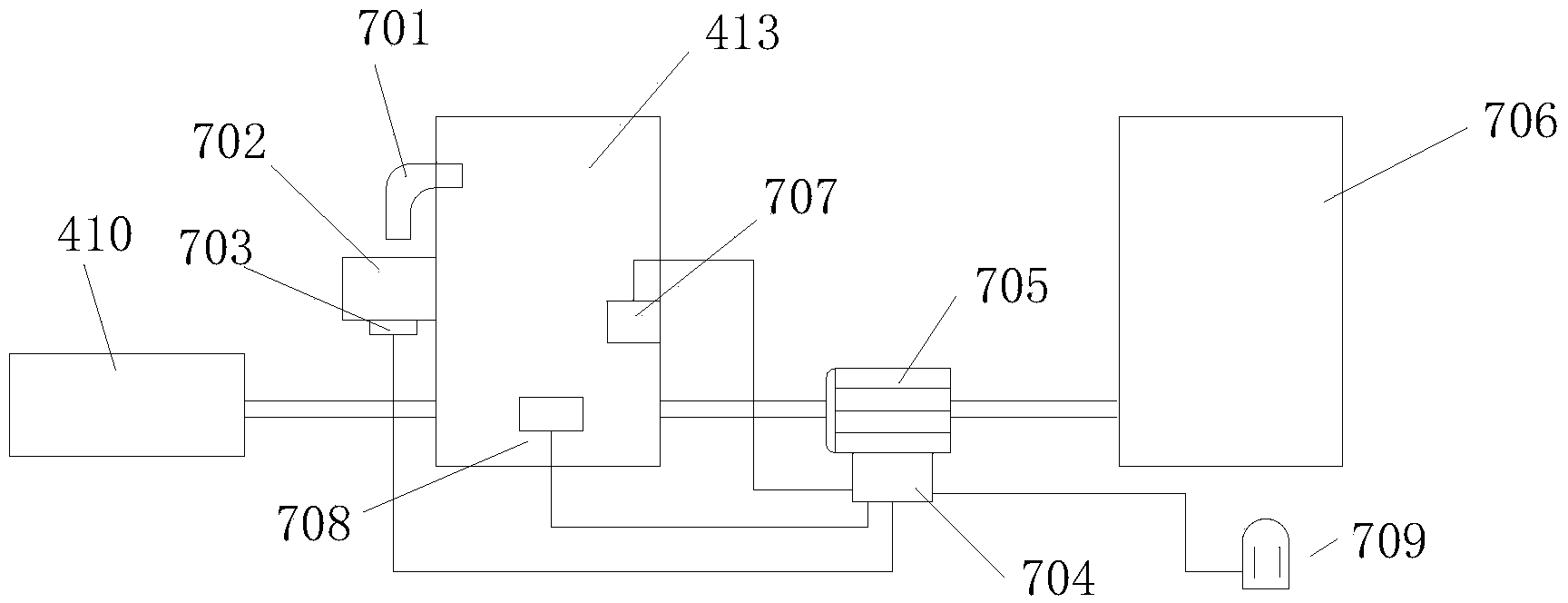

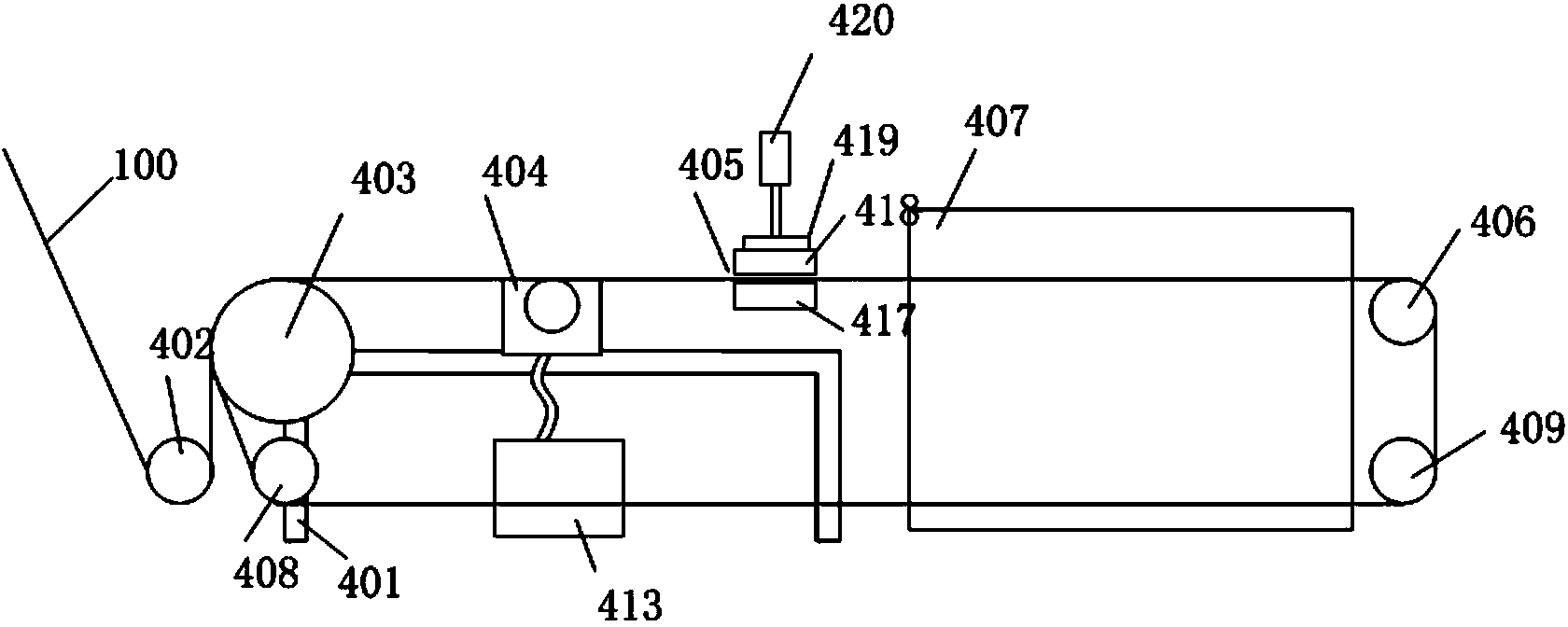

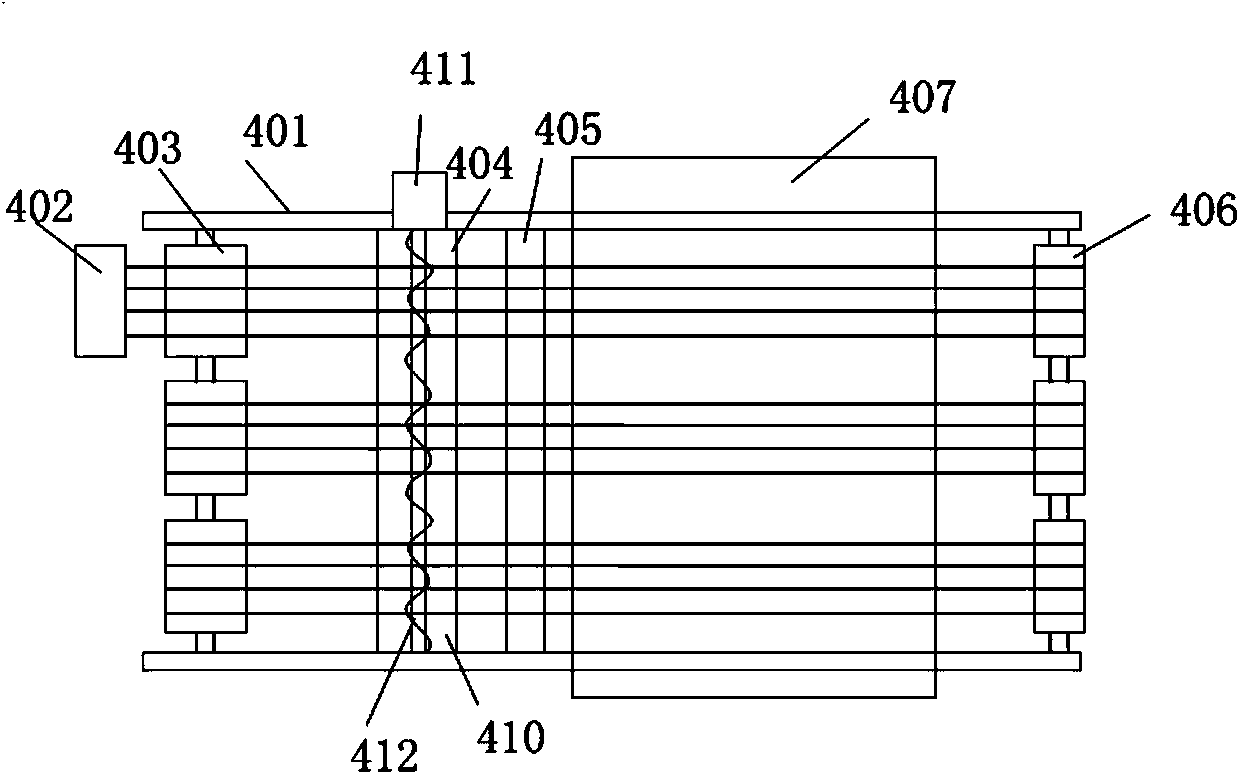

[0021] Embodiment: the broken paint alarm method of enamelling machine, this method is in enamelling machine painting process, when the paint filling liquid level sensor detects that the paint in the paint box drops to a certain liquid level, sends signal to controller, makes controller Start the paint pump to rotate forward, and drive the paint in the paint canister to be automatically transported into the paint box; when the paint liquid level in the paint box drops to the level of the low-level alarm level sensor, the low-level alarm level sensor sends a signal to the controller to control The sensor sends a signal to the alarm, so that the alarm sends out alarm information such as sound and light; when the paint in the paint box is full to a certain height, the paint overflows from the overflow pipe into the overflow box, and the weight sensor in the overflow box detects When there is liquid inflow, send a signal to the controller, the controller starts the paint pump to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com