Paint box spill protection method and mechanism of enamelling machine

A technology of enamelling machine and paint box, which is applied in the field of enameled wire manufacturing, which can solve the problems of paint overflow in paint box, loss of felt cotton layer, unsatisfactory surface removal effect of aluminum wire, etc., and achieve the effect of preventing paint overflow and paint overflow in paint box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

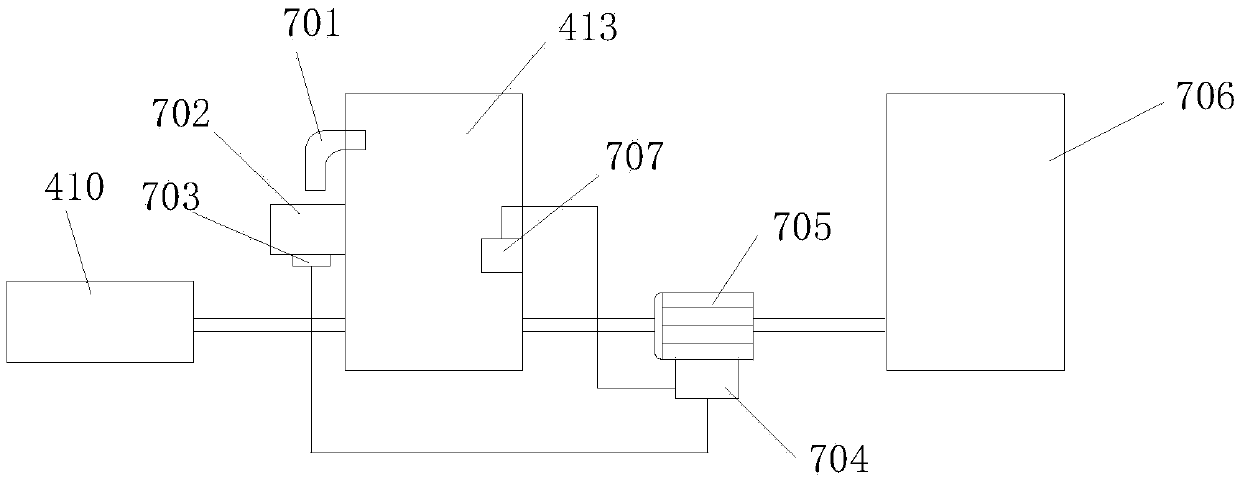

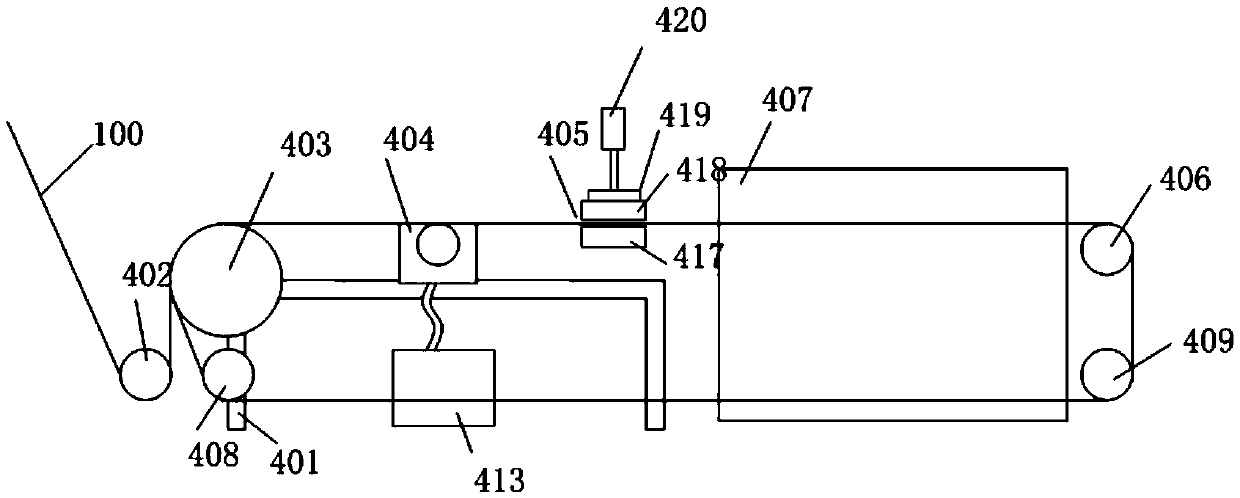

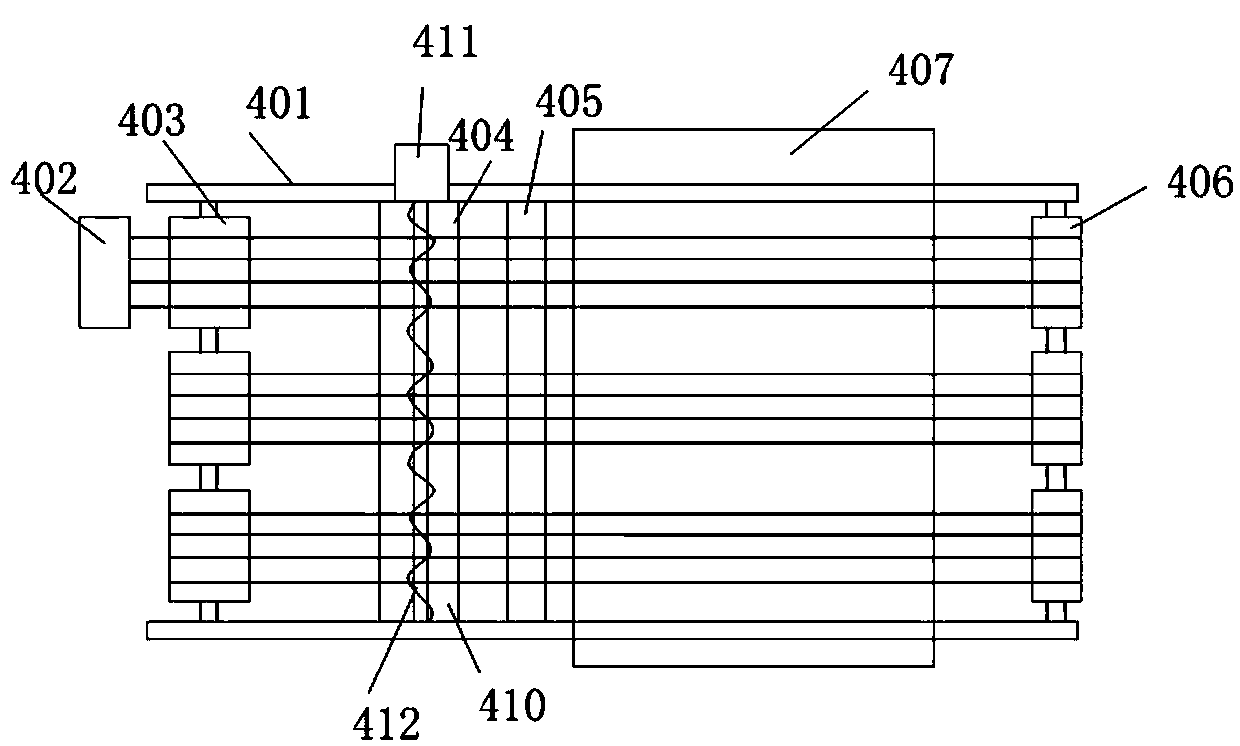

[0021] Embodiment: the paint protection method of the paint box of the enameling machine, the method is in the paint process of the enameling machine, when the liquid level sensor detects that the paint in the paint box drops to a certain liquid level, it sends a signal to the controller to make the controller. Start the paint pump to rotate forward, and drive the paint in the paint can to be automatically transported into the paint box; when the paint in the paint box is full to a certain height during the paint delivery process, the paint overflows from the overflow pipe to the overflow box. The weight sensor in the flow box detects the inflow of liquid and sends a signal to the controller. The controller starts the paint pump to reverse for a period of time and stops, not only stops supplying paint to the paint box, but also reverses the paint pump to make the paint in the paint box turn. Return a small amount of paint to the paint can, effectively preventing the paint box f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com