Drying method of enameling machine

An enameled machine and enameled wire technology, applied in electrical components, circuits, and conductor/cable insulation, etc., can solve problems such as loss of felt cotton layer, performance degradation of enameled wire, restricting painting effect, etc., to eliminate harmful gases and improve heating efficiency. , the effect of protecting workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

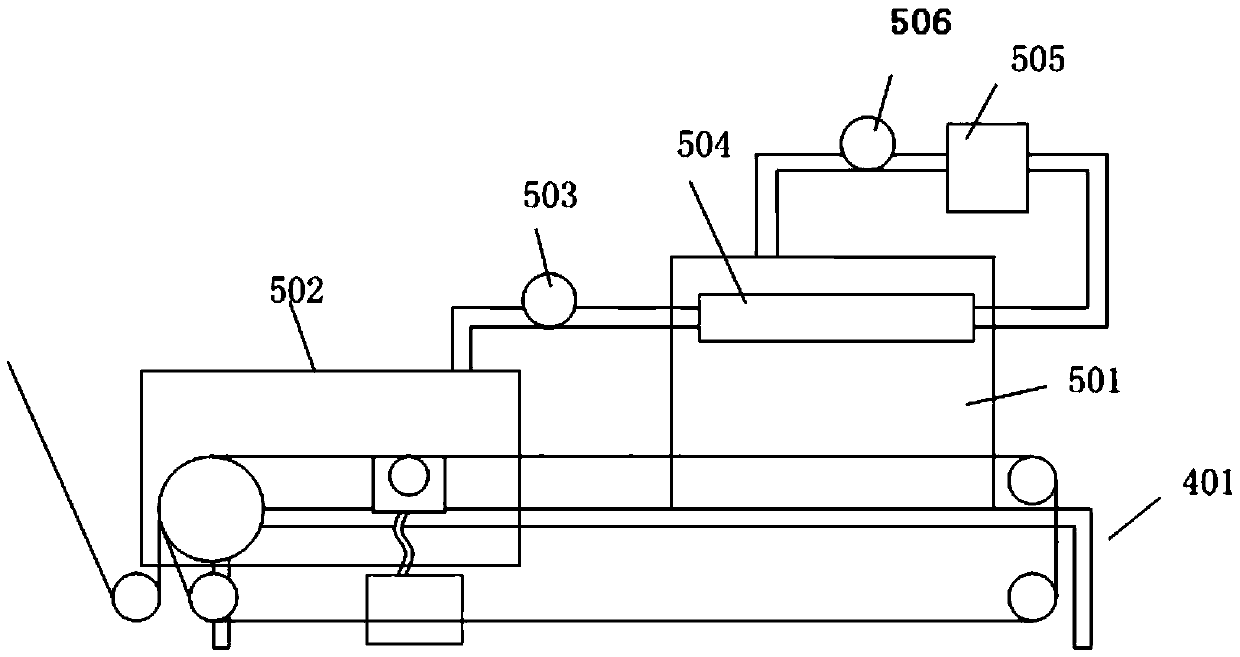

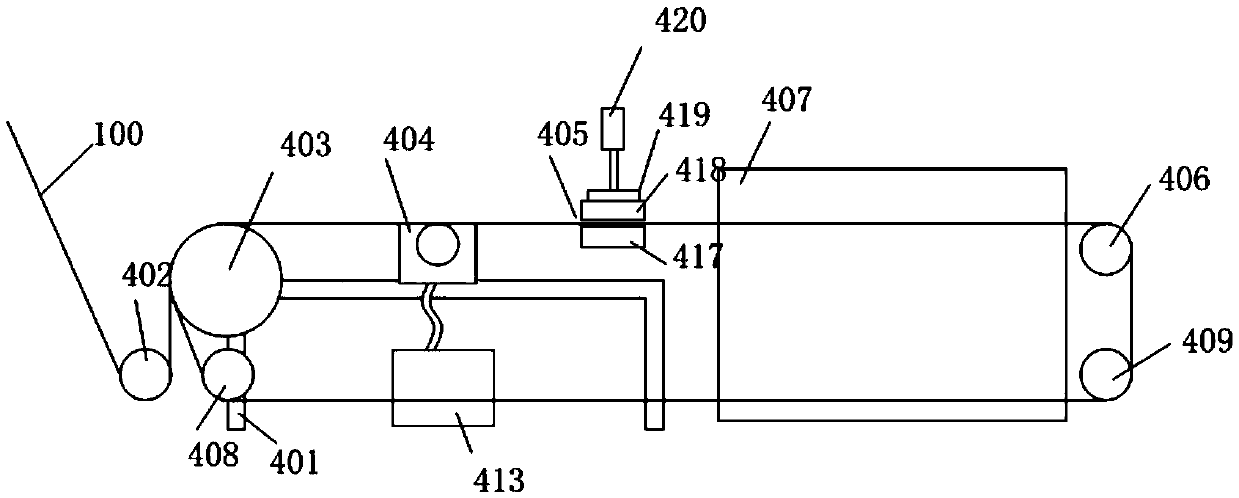

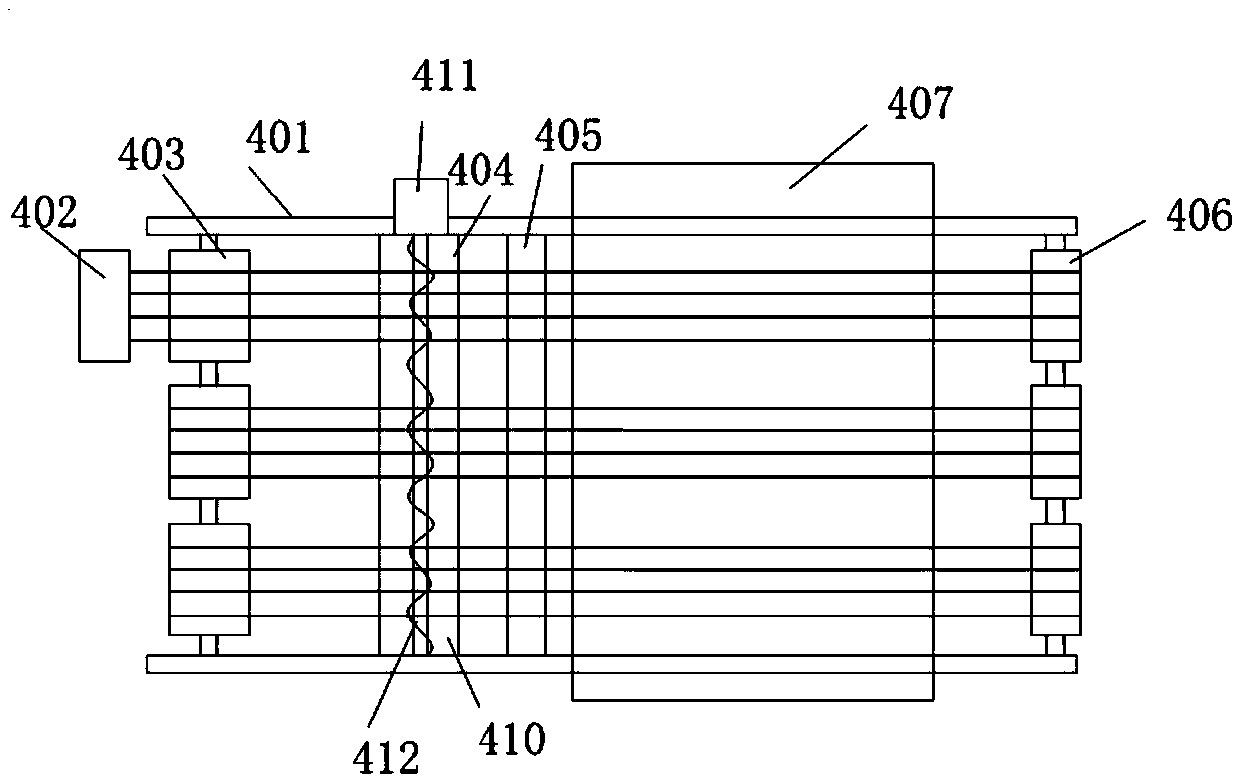

[0021] Embodiment: the drying method of enamelling machine, this method passes through the gas that painting mechanism produces through an outer cover and first passes into the heat exchange tube that is arranged in oven body and heats, and after heating, transports to catalytic combustion chamber and heats again into heat. The gas is passed into the oven body to heat and dry the enameled wire. Ovens for realizing drying methods such as enamelling machines, as attached figure 1 Shown, comprise frame 401, be provided with oven body 501 on frame 401, the front position of oven body 501 on frame 401 is provided with painting mechanism, the outside of painting mechanism is provided with a cover 502, and cover can be transparent The outer cover enables the gas to be collected effectively and allows workers to observe the operation of the painting mechanism. The outer cover 502 is connected with a first fan 503 through a pipeline, and the first fan 503 is connected with a heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com