Panel sprinkling curtain coating japanning equipment

A technology for drenching curtains and plates, which is applied to coatings, devices for coating liquids on surfaces, and surface pretreatment, etc. It can solve the problems of uneven paint layer, low processing efficiency, and many spraying workers, etc., and achieve the thickness of paint layer. Uniform, precise thickness control, uniform paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

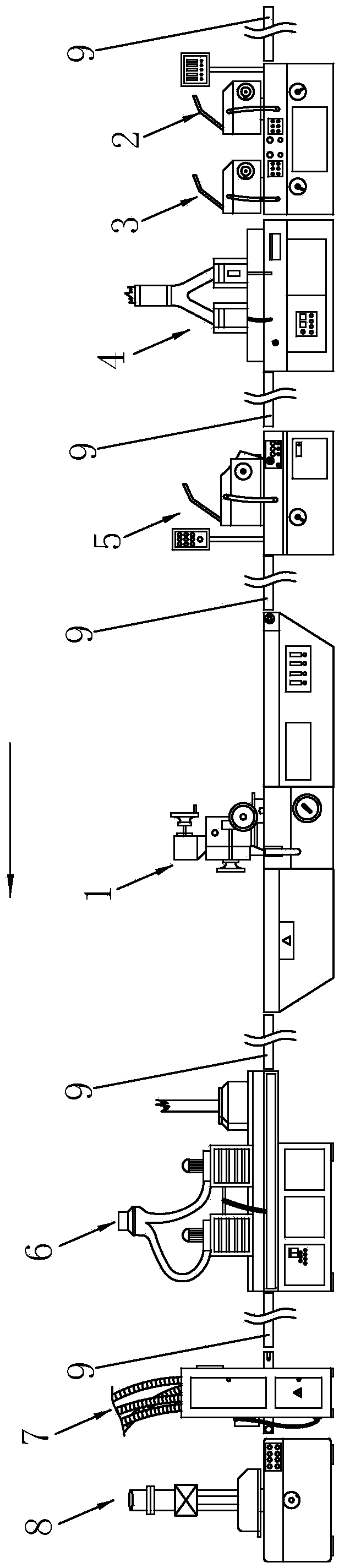

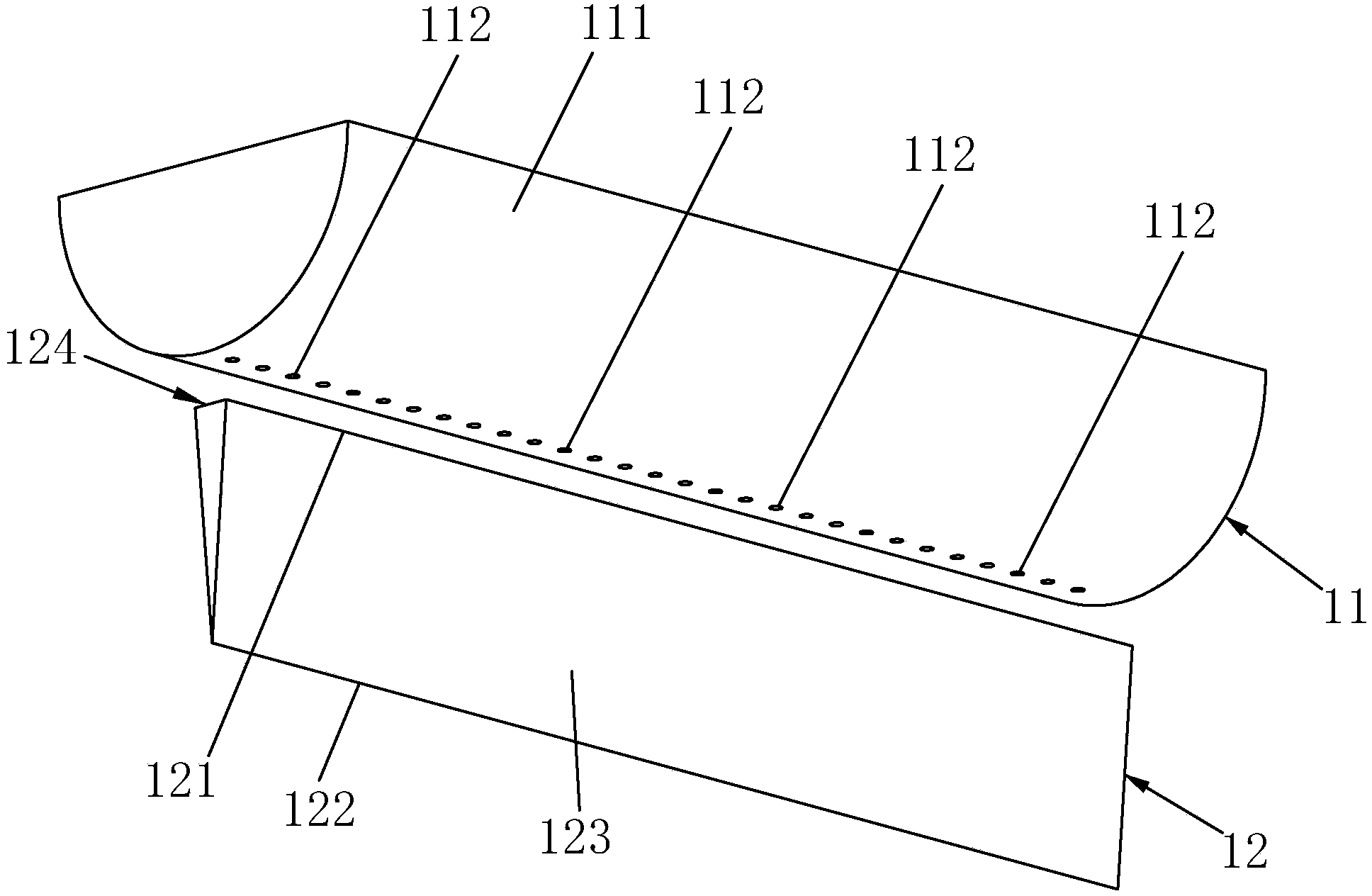

[0036] example, see Figure 1 to Figure 4 As shown in the figure, a panel curtain coating and painting equipment includes, in order from front to back, a greasy roller coating mechanism 2, a first primer roller coating mechanism 3, an ultraviolet drying and curing mechanism 4, and a second primer roller coating mechanism 4. Mechanism 5, curtain coating mechanism 1, ultraviolet drying mechanism 6, sanding mechanism 7 and dust removal mechanism 8.

[0037] The greasy roller coating mechanism 2 is located at the forefront,

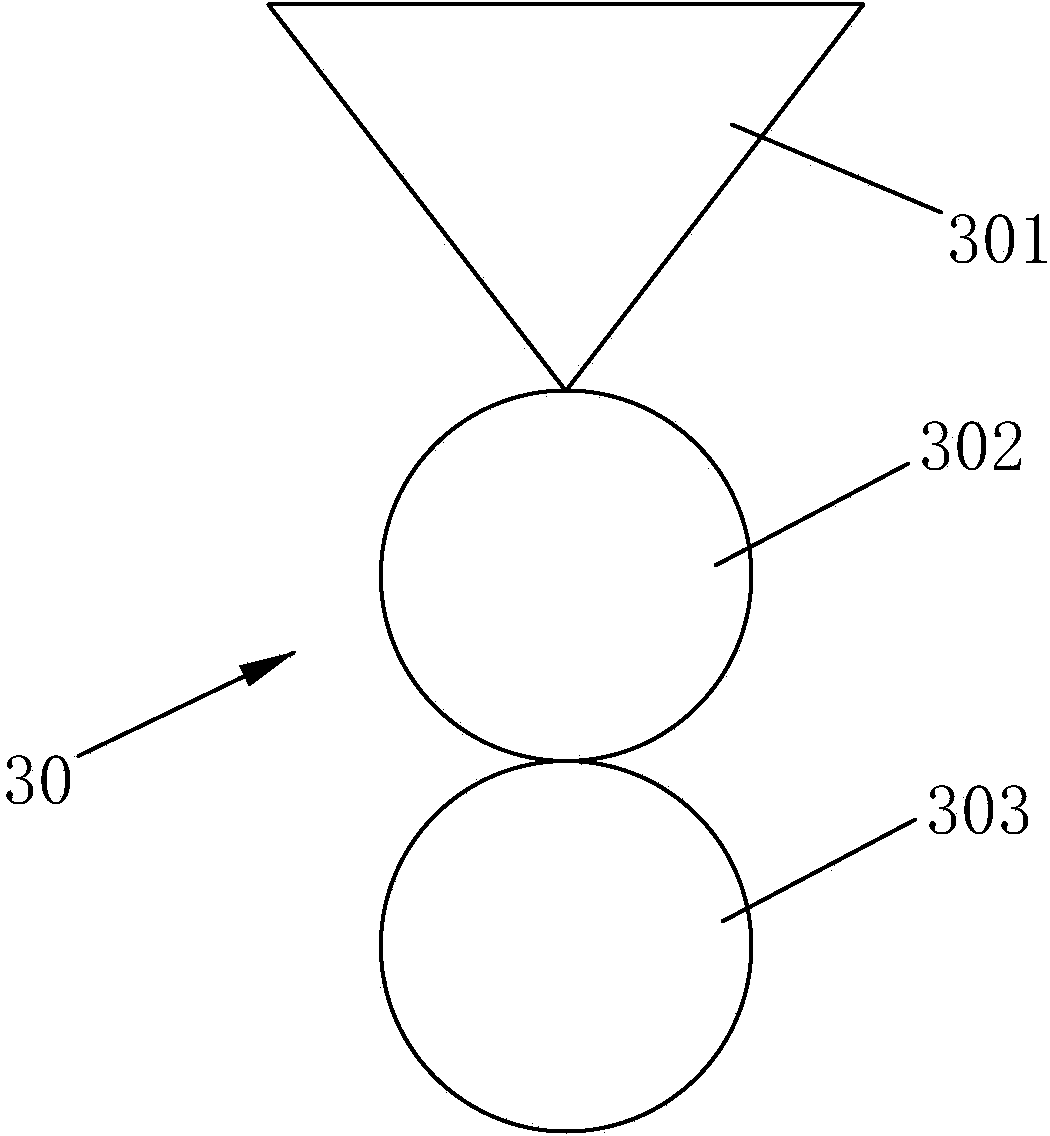

[0038] The first primer roller coating mechanism 3 is connected to the rear end of the greasy roller coating mechanism 2, and the first primer roller coating mechanism 3 is provided with a roller coating device 30;

[0039] The ultraviolet drying and curing mechanism 4 is connected to the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com