Fine enameled rectangular section conductor painting device

A technology of enamelled flat wire, painting device, applied in the direction of conductor/cable insulation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

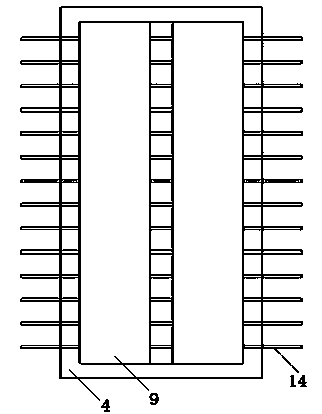

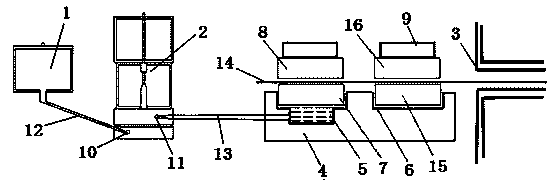

[0029] The micro enamelled flat wire painting device of the present embodiment, with reference to attached figure 2 , which includes a paint box 1, a painting device and an oven 3, the painting device includes a painting platform 4, the top of the painting platform 4 is provided with a paint liquid tank 5, and the top of the paint liquid tank 5 is provided with a first painting felt 7 , its lower part is dipped in the paint solution tank 5 and fixed relative to each other, its upper part is not lower than the upper surface of the painting platform 4, the first painting felt 7 top is correspondingly provided with the second painting felt 8, and the pressing plate 9 is pressed on The upper surface of the second painting felt 8; The right side of the paint liquid tank 5 corresponding to the painting platform 4 is provided with a concave groove 6, and the third painting felt 15 is fixed in it, and the third painting felt 15 is connected with the first painting felt. A paint felt ...

Embodiment 2

[0036] The micro enamelled flat wire painting device of the present embodiment, with reference to attached image 3 , Figure 4 , the structure of the device is basically the same as that of Embodiment 1, the main difference being that the size of the pressing plate 9 is equal to the size of the second painting felt 8 and the fourth painting felt 16, so as to level the painting felt in a larger area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com