Furniture plate placing rack

A technology for placing racks and boards, which is applied in the direction of surface pretreatment, coating, and devices for coating liquid on the surface. It can solve the problems of affecting the drying speed of the paint on the lower surface of the board, inconvenient movement, and large contact area. Problems, to achieve the effect of speeding up the drying speed, easy to move, and reduce the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

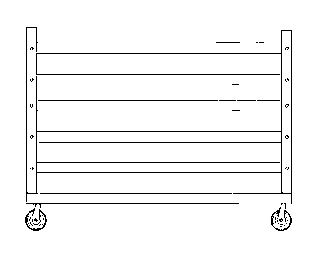

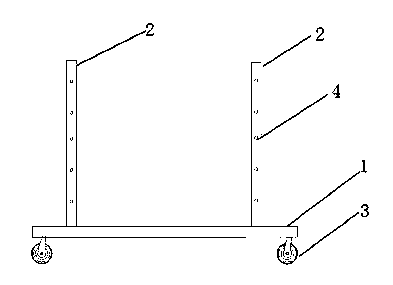

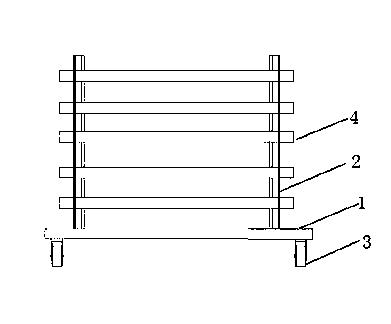

[0018] Such as figure 2 Attach image 3 Show, the furniture plates of this embodiment, including the side frame 2 connected to the left and right sides of the bottom frame 1 and the right side, the lower part of the bottom frame 1There are five horizontal rods on the left and right side 2 symmetrical settings, which are wrapped in the rubber material.

[0019] Such as Figure 4 Show, the furniture plates of this embodiment can be placed in multiple plates, and the board 5 that is painted or applied by paint or adhesive can be placed on the furniture plate placing rack.There are five horizontal rods 4 on the right side 2, and the left and right horizontal rod 4 on the same level supports a plate 5.The area of the board is stored in the area. At the same time, the board 5 is supported by two horizontal rods 4, which reduces the contact surface of the board 5 and the placing frame, and speeds up the drying speed of the surface paint on the surface of the board 5.The horizontal rod 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com