Method for making aluminium zipper with colorful galvanized coating

A production method and electroplating layer technology, which are applied in coating, gaseous chemical plating, metal material coating technology and other directions, can solve the problems of insufficiency of ultraviolet radiation, leaving cutting marks, brittle and fracture of germ teeth, etc. The effect of chemical erosion UV irradiation, improving performance, and improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

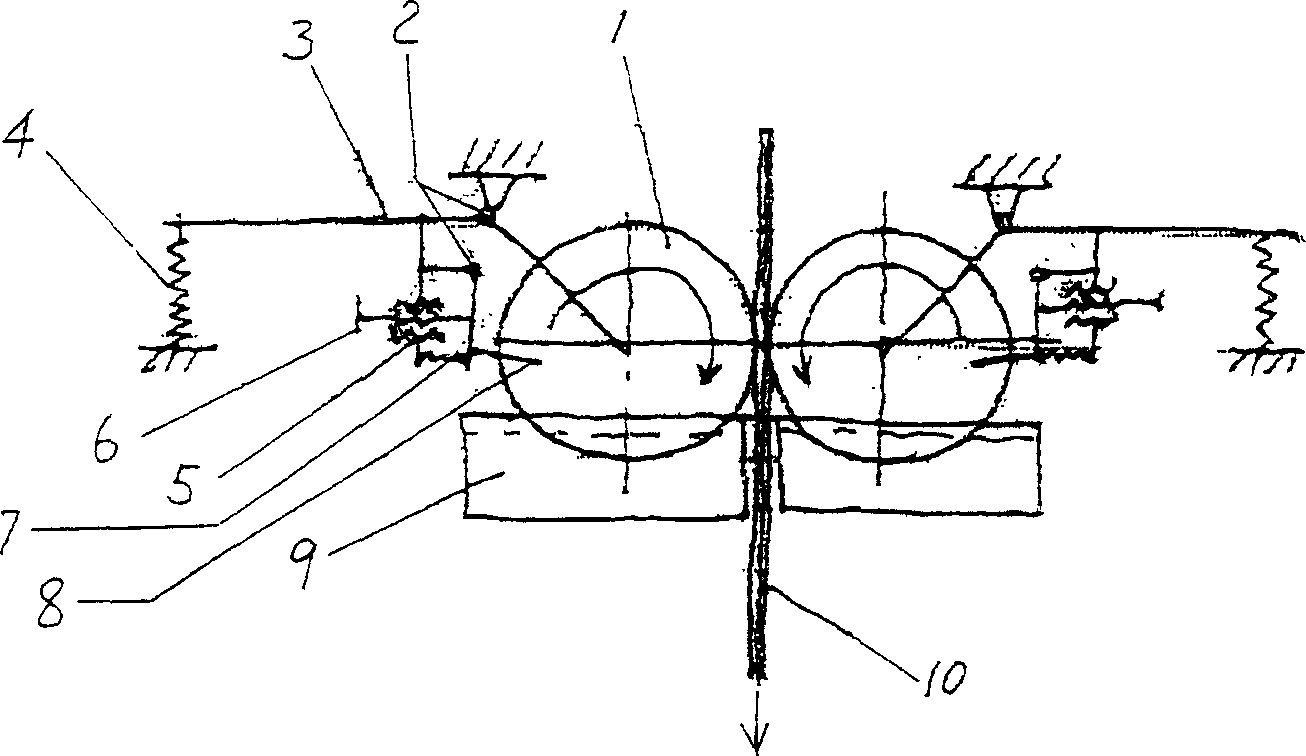

Image

Examples

Embodiment Construction

[0034] A kind of manufacturing method of the aluminum alloy zipper with colored electroplating layer of the present invention comprises the following manufacturing steps:

[0035] (1) Selecting materials to make embryos, using aluminum or aluminum alloy as the embryo tooth material, punching it into embryo teeth with an embryo-making machine; choosing a flat linear material made of aluminum alloy materials, and using a special embryo-making machine to make it Flat germ teeth punched into metal zippers;

[0036] (2) Grinding, using a grinding machine to grind the germ teeth with abrasives; mixing the germ teeth made in the above steps with abrasives and then grinding the surface of the germ teeth; Granules, the fineness of the abrasive grains is less than 100 mesh, and the grinding method adopted is centrifugal agitation;

[0037] (3), separation, the above-mentioned ground germ teeth are separated from the grinding material by an automatic sorter;

[0038] (4), cleaning, cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com