Painting mold frame capable of moving transversely and longitudinally and using method thereof

A technology of longitudinal movement and mold frame, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve problems such as unsatisfactory withstand voltage, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

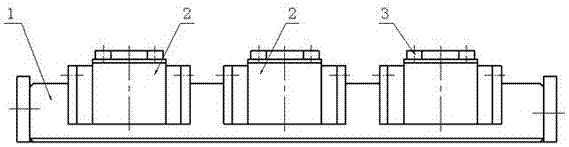

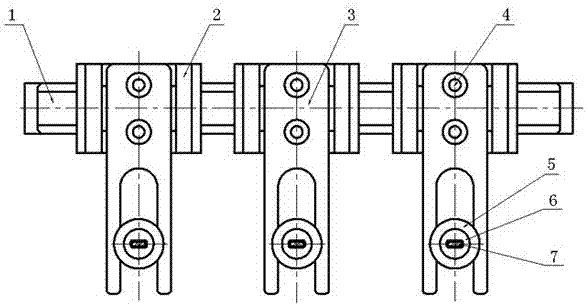

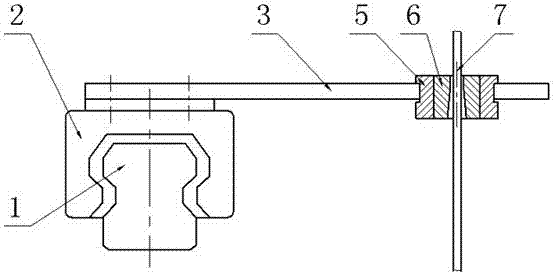

[0018] A painting mold rack that can move horizontally and vertically, including linear slide rails 1, sliders 2, U-shaped mold positioning frame 3, fixing bolts 4 and painting molds 5, the sliders 2 have 10 to 12 movable Set on the linear slide rail 1, the number of U-shaped mold positioning frame 3 matches the slider 2, and is fixedly connected with the slider 2 through the fixing bolt 4, and the painting mold 5 is movably arranged on the U-shaped mold positioning frame 3 inside the groove.

[0019] The center of the paint-painting mold 5 is provided with a paint-painting mold core 6 , and the center is provided with a hole matched with the paint-coating flat copper wire 7 .

[0020] A method for using a painting mold frame capable of moving horizontally and vertically, comprising the following steps:

[0021] A painting mold frame that can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com