Sheet material environment protection japanning technology free of formaldehyde

A technology for removing formaldehyde and sheet metal, which is applied to devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc. It can solve the problem of inability to quickly remove toxic and volatile substances, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

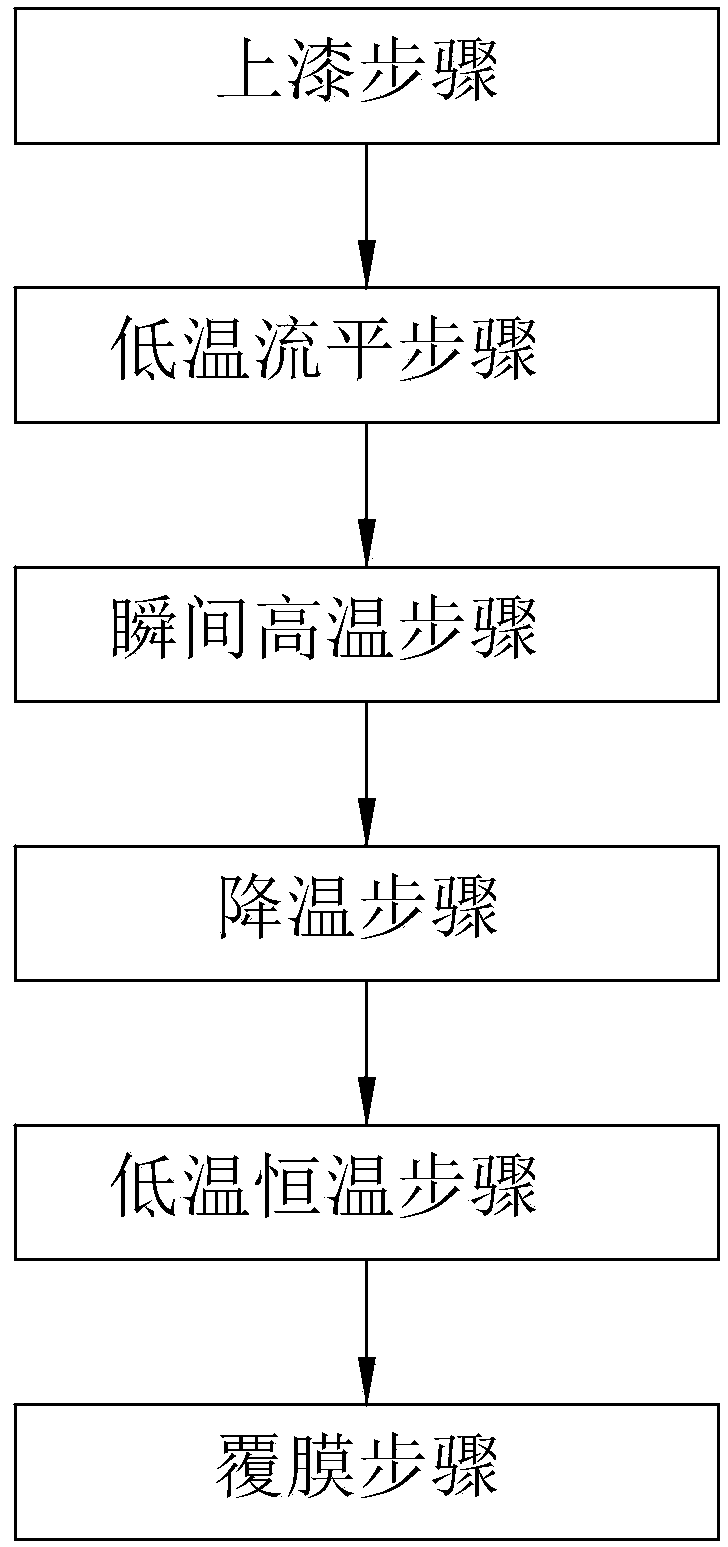

[0053] Examples, see Figure 1 to Figure 4 As shown, a formaldehyde-removing plate environmental protection painting process includes the following steps,

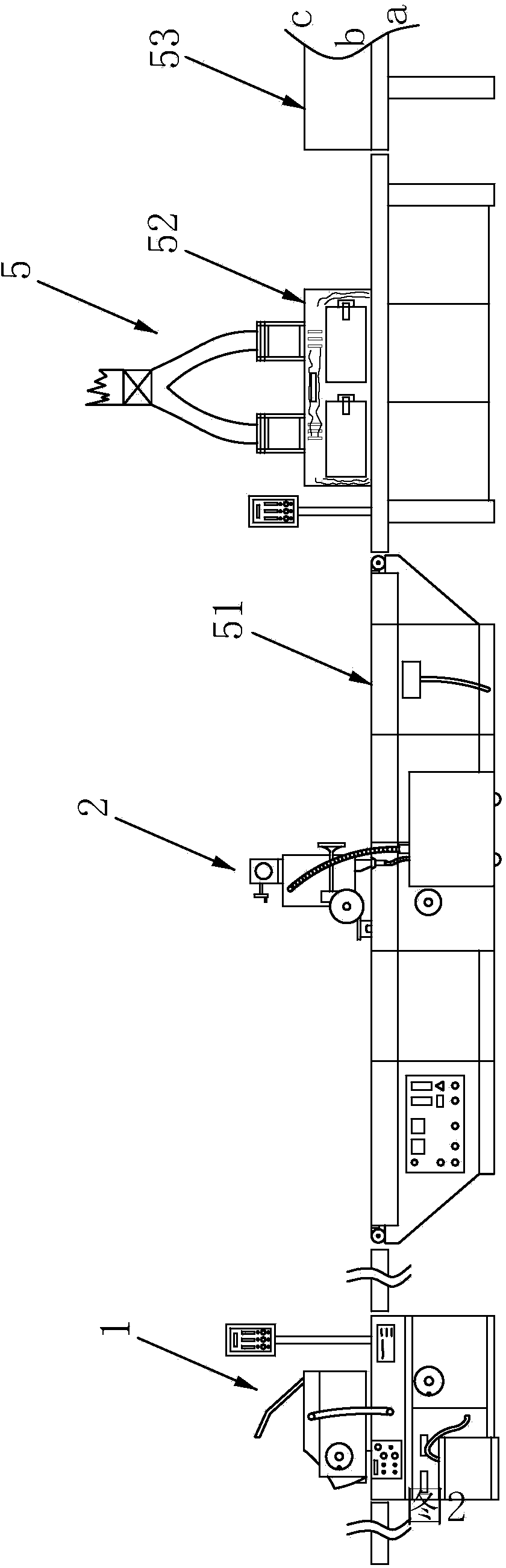

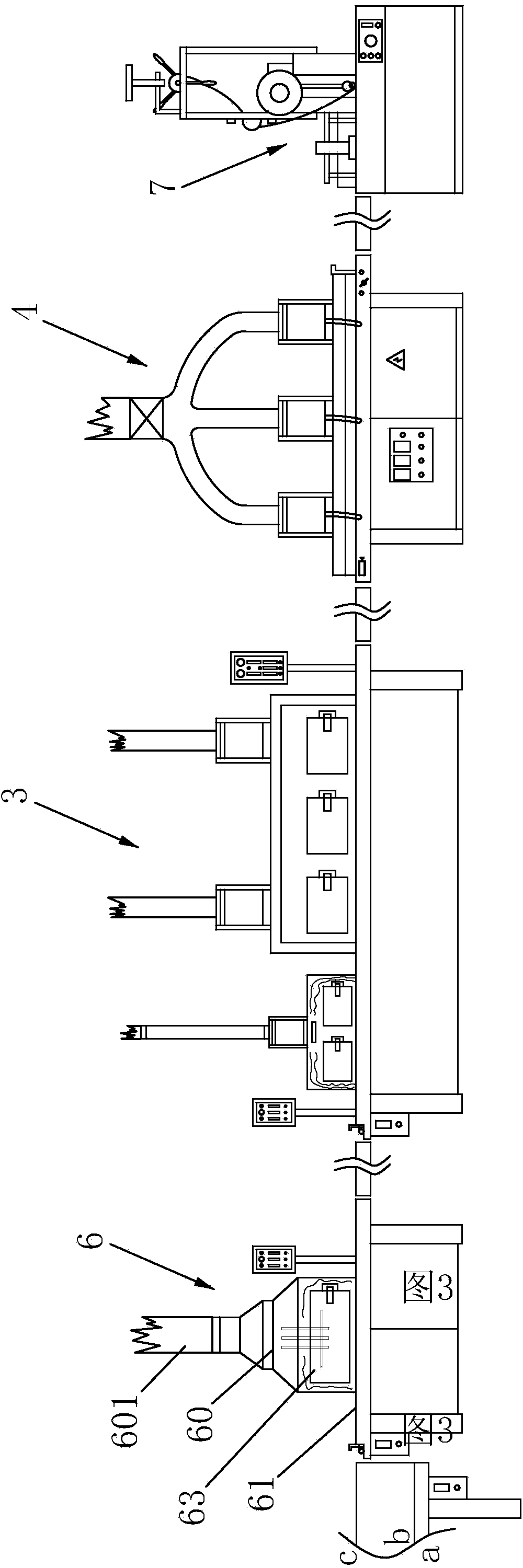

[0054] In the painting step, a layer of paint is attached to the surface of the board through a spraying process, a roller coating process or a flow coating process; specifically, the primer is first rolled on the surface of the board by the roller coating mechanism of the roller coating device 1 of the painting equipment; The flow coating mechanism of the flow coating device 2 of the painting equipment paints a layer of topcoat on the surface of the plate.

[0055] In the low-temperature leveling step, the low-temperature leveling pre-heating device 5 is used for low-temperature heating, the paint is water-based and leveled, and the temperature is 100-250 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com