Automatic painting device and application thereof

An automatic brushing and painting technology, which is applied in the direction of architecture and building construction, etc., can solve the problems of dangerous brushing at high places, time-consuming and labor-intensive manual painting, etc., and achieve the effects of convenient operation, waste reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

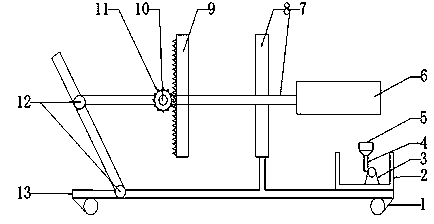

[0019] An automatic painting device, including a brake wheel plate 1, a paint box 2, a paint delivery pump 3, a hose 4, a paint spray head 5, a paint brush 6, a slider 7, a slide rail 8, a rack 9, and a speed control motor 10. Gear 11, screw pulley 12, cart 13, characterized in that: the brake wheel plate 1 is at the edge of the cart 13, there is a paint box 2 on the upper right of the cart 13, and the paint pump 3 is located in the center of the paint box, The paint spray head 5 is located above the paint pump 3, the paint spray head 5 is connected to the paint pump 3 through the hose 4, the paint brush is located directly above the paint spray head 5, the slider 7 and the upper left bracket of the trolley 13 pass through the screw pulley 12 Connected, a gear 11 is installed on the left side of the slider 7, a speed control motor is arranged in the gear 11, the rack 9 is located on the right side of the gear 11, the two are closely connected, the slide rail 8 is located direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com