Protection method applicable to chaste tree twig woven products

A technology of braided products and Vitex, which is applied in the field of protection of Vitex braided products, can solve the problems of greater influence of fiber structure temperature changes, unstable mechanical properties, and low utilization rate, so as to improve mechanical properties, reduce instability problems, and dry speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

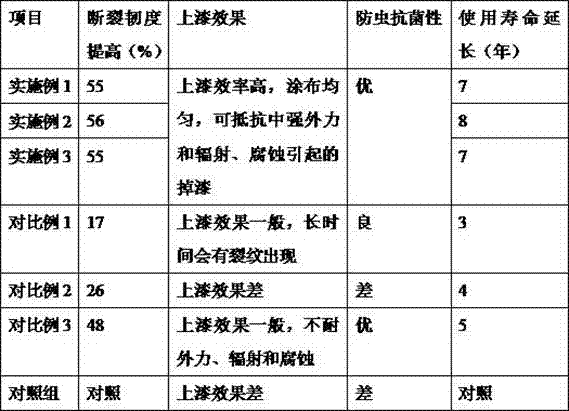

Examples

Embodiment 1

[0017] A protective method suitable for braided wattle, comprising the following steps:

[0018] (1) Heat the newly made Vitex woven fabric at a temperature of 70°C for 30 minutes, then place it at 0°C for 20 minutes, repeat twice, and soak the Vitex woven fabric after alternating cold and heat treatment for 5 minutes , take it out and put it in a 50°C oven for 1 hour;

[0019] (2) Spray the pretreated Vitex woven fabrics evenly with the base liquid, which is made of the following ingredients according to the mass percentage: 15% methyl p-hydroxybenzoate, 14% phenoxyethanol, 12-hydroxystearin 11% triglyceride, 6% disodium edetate, 5% neoprene latex, 2% carrageenan, 1% methylcellulose, and the rest is 1,2-propanediol;

[0020] (3) Put the uniformly sprayed Vitex weave in the drying room to dry, and prepare for painting. Immerse the dried Vitex weave completely in the prepared paint solution, and slowly lift the Vitex weave after 5 seconds until it is completely removed. Paint...

Embodiment 2

[0027] A protective method suitable for braided wattle, comprising the following steps:

[0028] (1) Heat the newly made Vitex woven fabric at a temperature of 75°C for 40 minutes, then place it in an environment of 2°C for 25 minutes, repeat twice, and soak the Vitex woven fabric after alternating cold and heat treatment for 7 minutes , take it out and bake it in a 55°C oven for 1.5 hours;

[0029] (2) Spray the pretreated Vitex woven fabrics evenly with the base liquid, which is made of the following ingredients according to the mass percentage: 16% methyl p-hydroxybenzoate, 16% phenoxyethanol, 12-hydroxystearin 12% triglyceride, 7% disodium edetate, 6% neoprene latex, 3% carrageenan, 2% methylcellulose, and the rest is 1,2-propanediol;

[0030] (3) Put the uniformly sprayed Vitex weave in the drying room to dry, and prepare for painting. Completely immerse the dried Vitex weave in the prepared paint solution, and slowly lift the Vitex weave after 7 seconds until it leaves ...

Embodiment 3

[0037] A protective method suitable for braided wattle, comprising the following steps:

[0038] (1) Heat the newly made Vitex woven fabric at 80°C for 50 minutes, then place it at 5°C for 30 minutes, repeat 3 times, soak the Vitex woven fabric after alternating cold and heat treatment for 10 minutes , take it out and bake it in a 60°C oven for 2 hours;

[0039] (2) Spray the pretreated Vitex woven fabrics evenly with the base liquid, which is made of the following ingredients according to the mass percentage: 17% methyl p-hydroxybenzoate, 18% phenoxyethanol, 12-hydroxystearin 13% triglyceride, 8% disodium edetate, 7% neoprene latex, 4% carrageenan, 3% methylcellulose, and the rest is 1,2-propanediol;

[0040] (3) Put the evenly sprayed Vitex weave in the drying room to dry, and prepare for painting. Immerse the dried Vitex weave completely in the prepared paint solution, and slowly lift the Vitex weave after 10 seconds until it leaves completely. Paint solution, hang it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com