Wooden door surface plate sealing type painting device and method

A sealed, surface-mounted technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as unfavorable health of workers, difficult to remove, difficult to apply paint, etc., to avoid physical problems. Damage to health, avoid worker inhalation, improve the effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

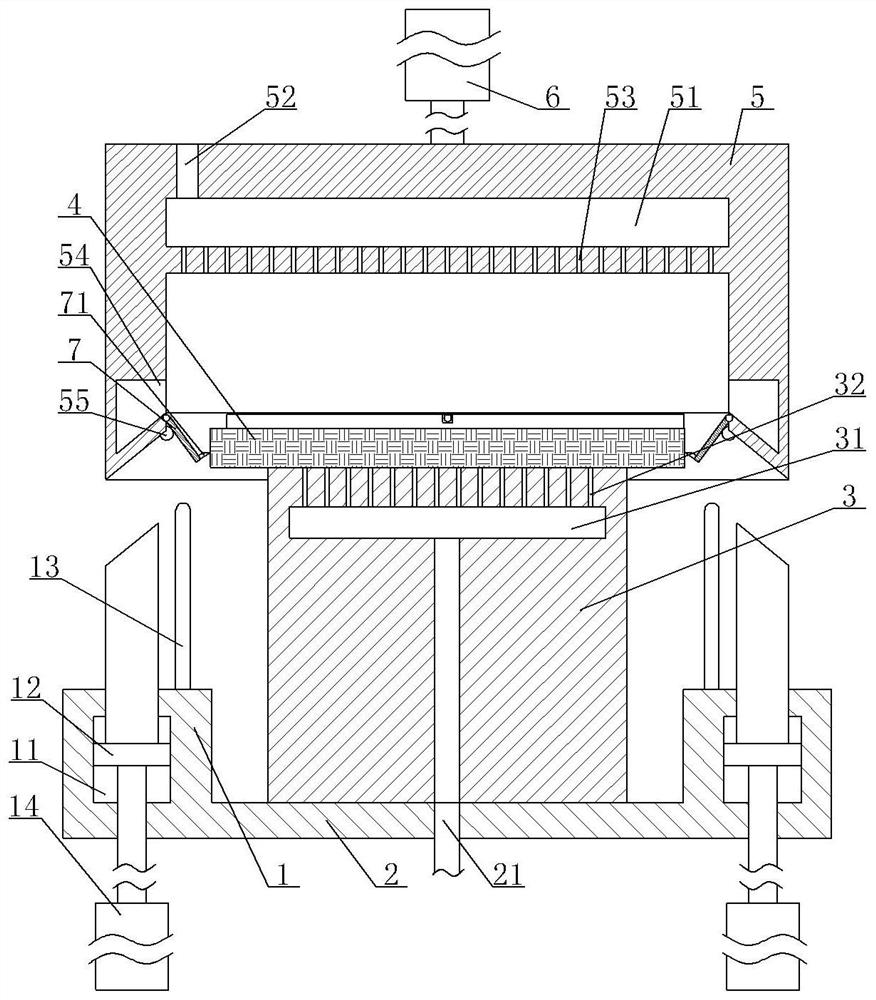

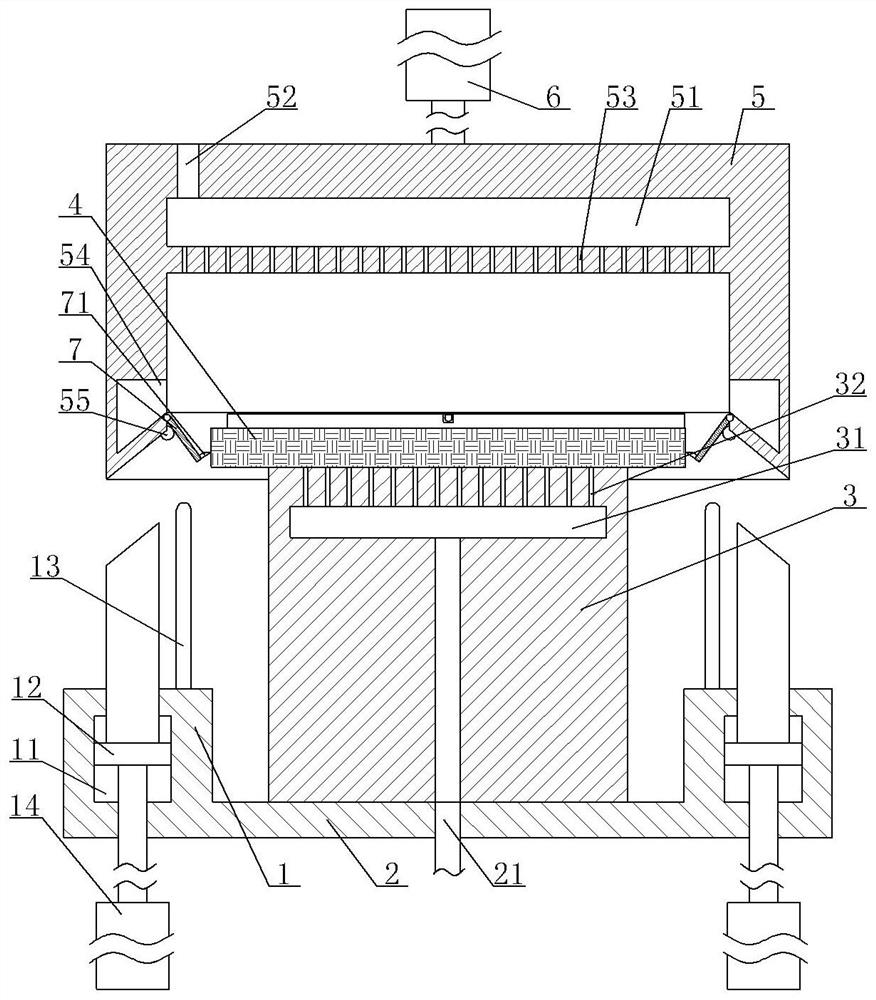

[0043] Sealed painting equipment for wooden door panels, such as figure 1 , figure 2 and image 3 As shown, it includes a frame, a workbench 3, a side plate 1 and a mobile unit. A horizontal bottom plate 2 is provided under the side plate 1. The side plate 1 is ring-shaped. The bottom plate 2 and the side plate 1 are integrally formed, and the bottom plate 2 is welded on the machine. On the frame, the workbench 3 is welded on the base plate 2, and the workbench 3 is located at the inner periphery of the side plate 1. The length and width of the workbench 3 in this embodiment are respectively less than the length and width of the door panel 4. The workbench 3 is provided with a negative pressure chamber 31, and the bottom of the workbench 3 is provided with an exhaust port communicating with the negative pressure chamber 31. The bottom plate 2 is glued with an exhaust pipe 21, and the upper end of the exhaust pipe 21 runs through the bottom plate 2 and connects with the exhau...

Embodiment 2

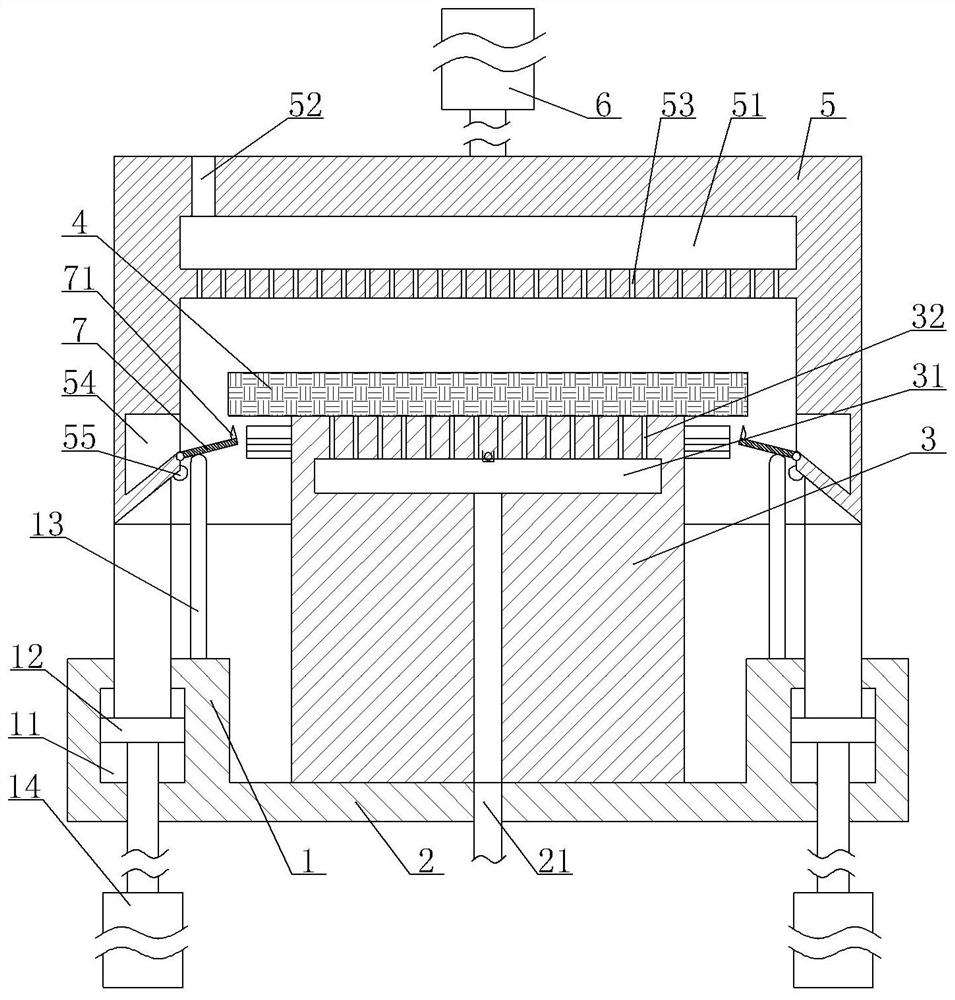

[0056] On the basis of Example 1, such as Figure 4 As shown, the guide plate 7 and the cutter 71 in the painting equipment in the present embodiment are all iron, and the bump 55 includes a base 552 and a second permanent magnet block 551, and the base 552 is welded on the inner wall of the sealing cover 5, A groove 57 is formed on the side wall of the base 552 facing the workbench 3 , and the second permanent magnet block 551 is interference fit with the groove 57 . Sealing cover 5 inner wall is provided with opening towards the limit groove of workbench 3, and limit groove is positioned at the top of recovery mouth, and when cutter 71 cuts paint, the end of cutter 71 can stretch in the limit groove, Avoid the blade portion of the cutter 71 from directly abutting against the inner wall of the sealing cover 5 to cause the blade portion of the cutter 71 to be damaged. Four first permanent magnet blocks 56 are embedded in the sealing cover 5, and the first permanent magnet blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com