Magnesium alloy auto hub and its producing method

A technology of automobile wheel hub and manufacturing method, which is applied to the direction of wheels, wheel cover plates, vehicle parts, etc., can solve the problems of difficult to meet the standard requirements for degassing, easy segregation of components, and difficult slag removal of molten aluminum, so as to achieve enhanced operation reliability, Low manufacturing cost and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

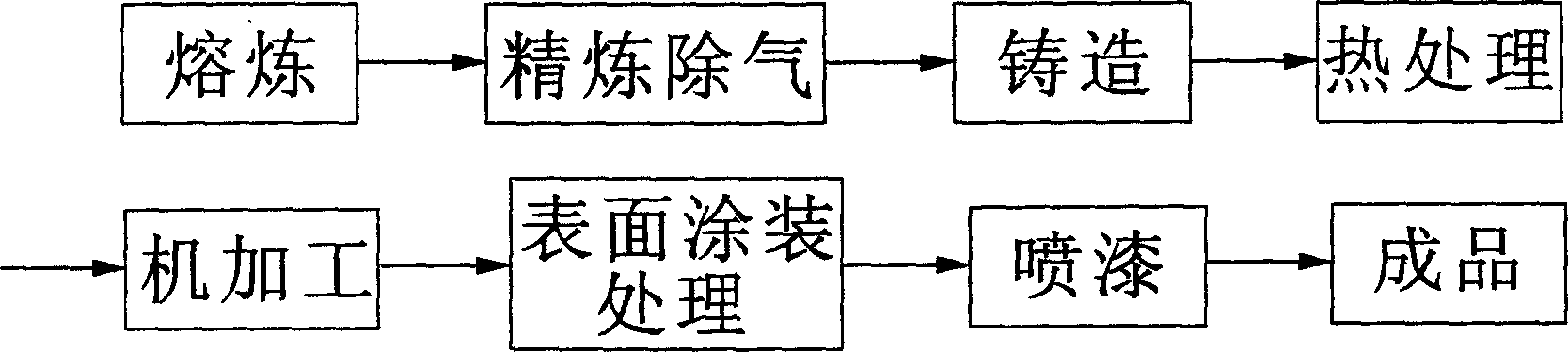

[0024] Its prescription ratio of the magnesium alloy automobile wheel hub of the present invention is calculated by weight percentage: its manufacturing method adopts the following process steps:

[0025] The model of the magnesium alloy wheel hub of the present invention is: 0105-1350, diameter: 13 inches, width: 5 inches.

[0026] 1. Melting: Take 90% of the main raw material magnesium alloy ingot, preheat and dry it, drying temperature: 120-160°C, drying time: 1.5-2 hours; put the preheated magnesium alloy ingot into the crucible, heat up and melt, The temperature of molten magnesium is: 750-770°C. After melting for 30-40 minutes, turn on the protective gas, which is 25% N2+75% H2, to protect the magnesium alloy in the crucible, and add an intermediate alloy: aluminum agent (AI) : 9%, zinc agent (Zn): 0.5%, silicon agent (Si): 0.05%, iron agent (Fe): 0.002%, manganese agent (Mn): 0.444%, copper agent (Cu) : 0.002%, sodium agent (Ni): 0.002%; fully stir and mix evenly, and ...

Embodiment 2

[0036] Its formula ratio of magnesium alloy automobile wheel hub of the present invention is by weight percentage:

[0037] The model of the magnesium alloy wheel hub of the present invention is: 0102-1240, diameter: 12 inches, width: 4 inches.

[0038] The present invention gets main raw material magnesium alloy ingot: 89.5%, intermediate alloy gets: aluminum agent (AI) is: 9.5%, zinc agent (Zn) is: 0.5%, silicon agent (Si) is: 0.05%, iron agent ( Fe) is: 0.002%, manganese agent (Mn) is: 0.444%, copper agent (Cu) is: 0.002%, sodium agent (Ni) is: 0.002%; its manufacturing method adopts the process steps in embodiment one to make Magnesium alloy automobile wheel has beautiful appearance, light weight, high strength, good toughness, not easy to deform, and good corrosion resistance.

Embodiment 3

[0040] Its formula ratio of magnesium alloy automobile wheel hub of the present invention is by weight percentage:

[0041] The present invention gets main raw material magnesium alloy ingot: 90.5%, intermediate alloy gets: aluminum agent (AI) is: 8.3%, zinc agent (Zn) is: 0.5%, silicon agent (Si) is: 0.05%, iron agent ( Fe) is: 0.002%, manganese agent (Mn) is: 0.444%, copper agent (Cu) is: 0.002%, sodium agent (Ni) is: 0.002%; adopt the process step in embodiment one, two to make Magnesium alloy automobile wheels also meet the requirements of various indicators. Its model size can be formulated according to the needs of manufacturers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com