Method for propelling hole alignment and preventing paint collision in japanning process of chopstick blank machine and special device for method

A special device, technology of chopsticks embryo, applied to the device and coating of the surface coating liquid, can solve the problems of endangering production efficiency and high manual operation intensity, and achieve the effect of low manufacturing cost and simple device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

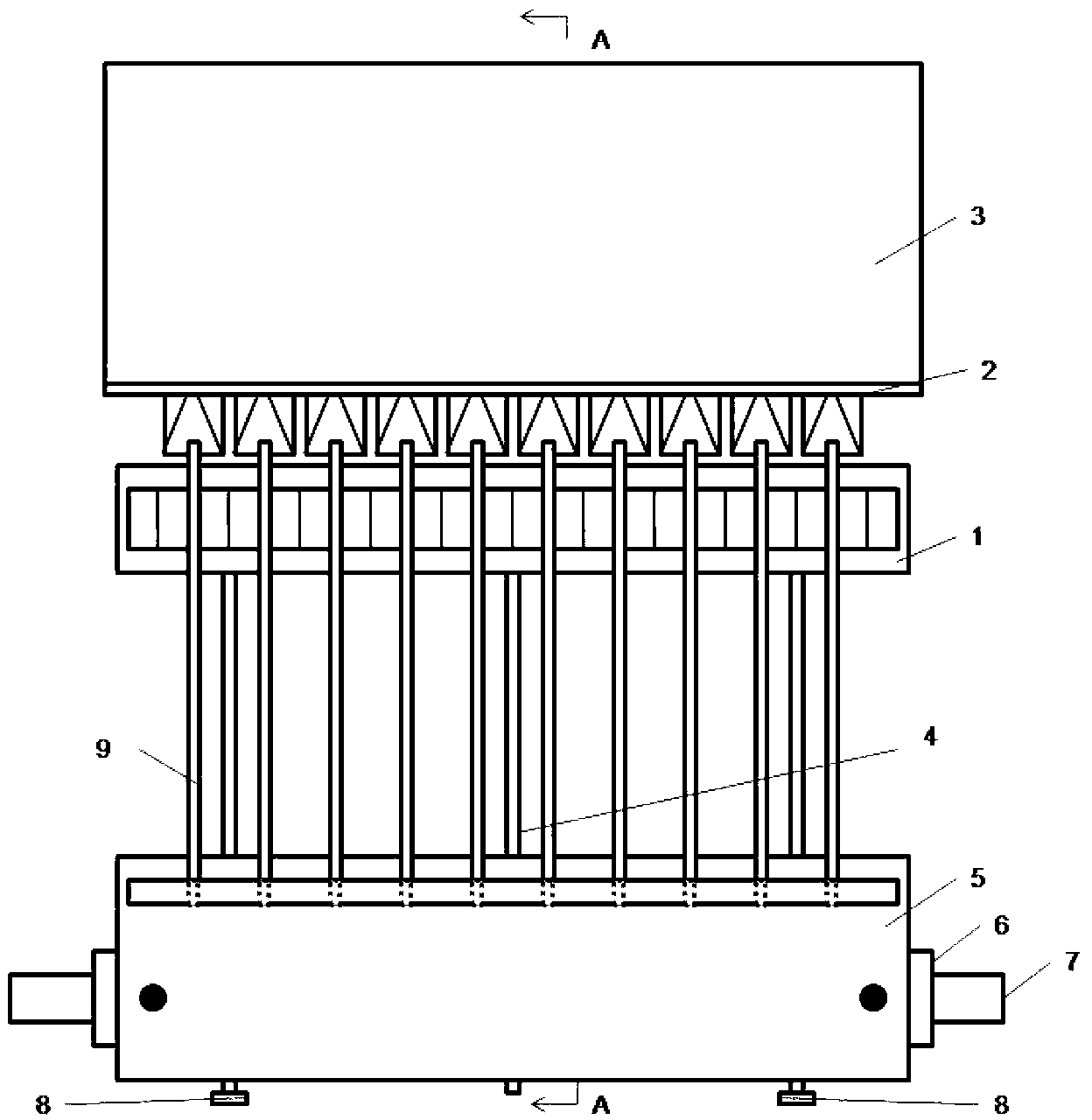

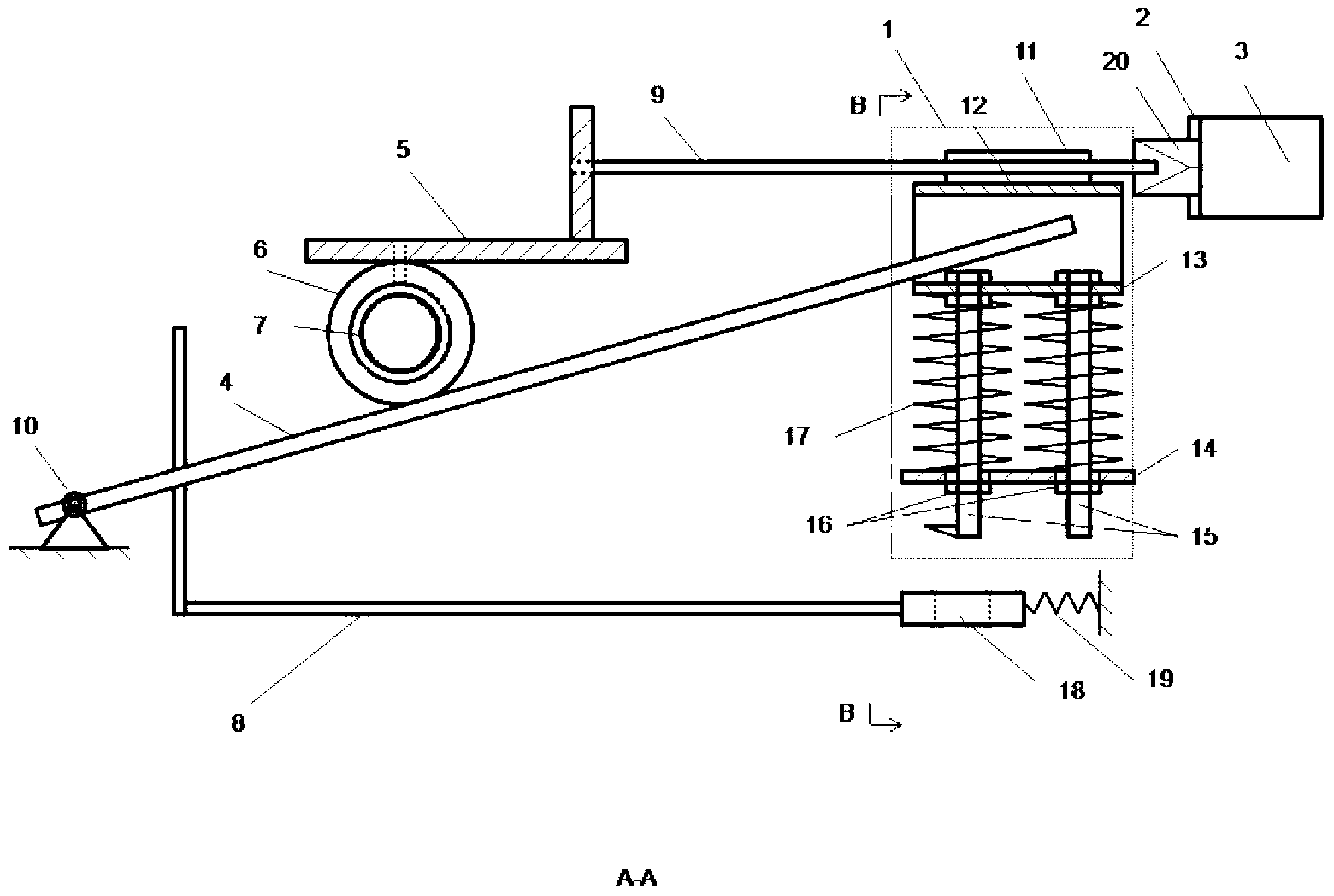

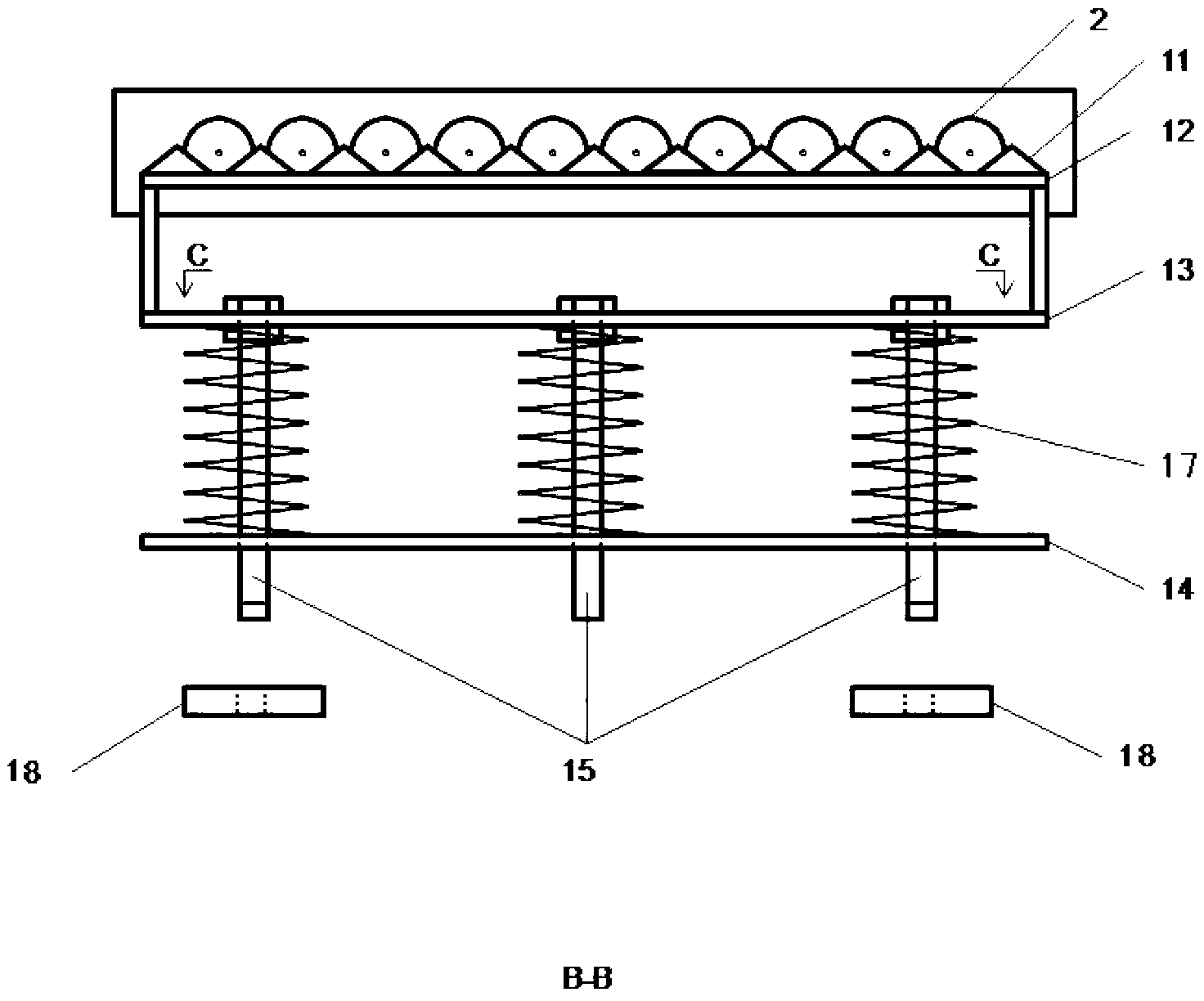

[0025] refer to Figure 1 to Figure 4 , the chopsticks embryo is machine-painted to advance the method for aligning holes and anti-collision paint, and the steps of the method are as follows:

[0026] (1) Preparation: The guide groove assembly 1 rises vertically and resets, the guide groove 11 is aligned with the rubber block 20 hole centers on the rubber guide hole plate 2 at the inlet end of the paint box 3, and the chopstick board 5 on which the chopstick embryo 9 is placed is set on the The rotation of the sleeve 6 on the motor drive rod 7 places the chopsticks embryo 9 in the guide groove 11;

[0027] (2) Propelling: the motor drive rod 7 pushes the chopsticks blank 9 forward along the guide groove 11, and the chopsticks blank 9 is introduced into the paint box 3 through the rubber guide plate 2 on the paint box 3;

[0028] (3) Separation of the chopsticks groove: After the chopsticks blank 9 is introduced into the paint box 3, the motor drive rod 7 pushes the guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com