Building component japanning device

A technology of building components and mounting seats, which is applied in the direction of spraying devices, etc., can solve the problems of uneven painting effect, unstable painting effect, and inability to paint, etc., to achieve stable driving and uniform speed, uniform and stable painting effect, Stable effect in the varnishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

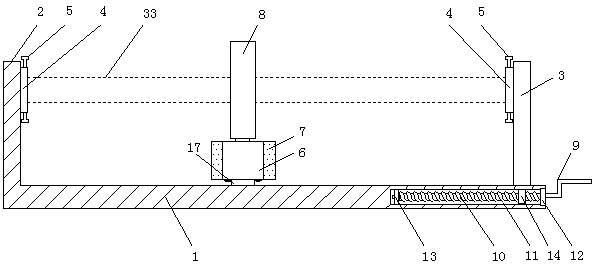

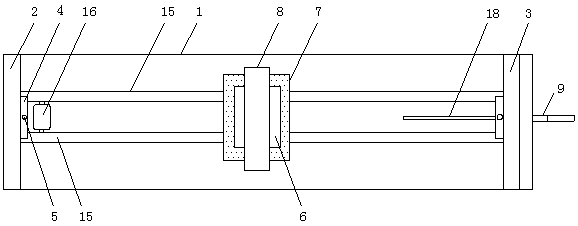

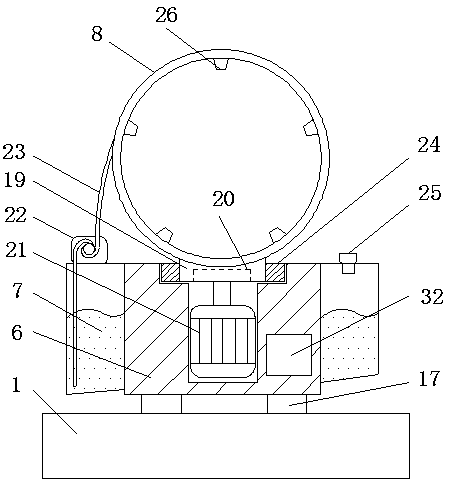

[0023] like Figure 1-8 As shown, the painting device for building components includes a base 1, the left side of the base 1 is provided with a fixed plate 2, the right side of the base 1 is provided with a movable plate 3, and the center of the bottom of the movable plate 3 is provided with a nut 14, Described nut 14 cooperates with screw mandrel 10, and described screw mandrel 10 is fixed in cylindrical groove 11 by front bearing 12 and rear bearing 13 respectively, and the outside of described front bearing 12 is provided with the handle 9 that is fixedly connected with screw mandrel 10 , the upper part of the cylindrical groove 11 is provided with a rectangular groove 18 for the nut 14 to move, the fixed plate 2 and the movable plate 3 are provided with a fixed ring 4, and the top and bottom of the fixed 4 rings are provided with fastening rings. Bolt 5, the lower part of the fastening bolt 5 is provided with an arc-shaped pressure plate 28, the upper part of the base 1 is...

Embodiment 2

[0026] like Figure 1-8 As shown, the painting device for building components includes a base 1, the left side of the base 1 is provided with a fixed plate 2, the right side of the base 1 is provided with a movable plate 3, and the center of the bottom of the movable plate 3 is provided with a nut 14, Described nut 14 cooperates with screw mandrel 10, and described screw mandrel 10 is fixed in cylindrical groove 11 by front bearing 12 and rear bearing 13 respectively, and the outside of described front bearing 12 is provided with the handle 9 that is fixedly connected with screw mandrel 10 , the upper part of the cylindrical groove 11 is provided with a rectangular groove 18 for the nut 14 to move, the fixed plate 2 and the movable plate 3 are provided with a fixed ring 4, and the top and bottom of the fixed 4 rings are provided with fastening rings. Bolt 5, the lower part of the fastening bolt 5 is provided with an arc-shaped pressure plate 28, the upper part of the base 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com