Hot pressing forming machine with die collecting device

A molding machine and driving device technology, applied to household appliances, other household appliances, household components, etc., can solve the problems of inconvenient operation, high labor intensity, time-consuming and laborious, etc., and achieve the effect of convenient operation and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

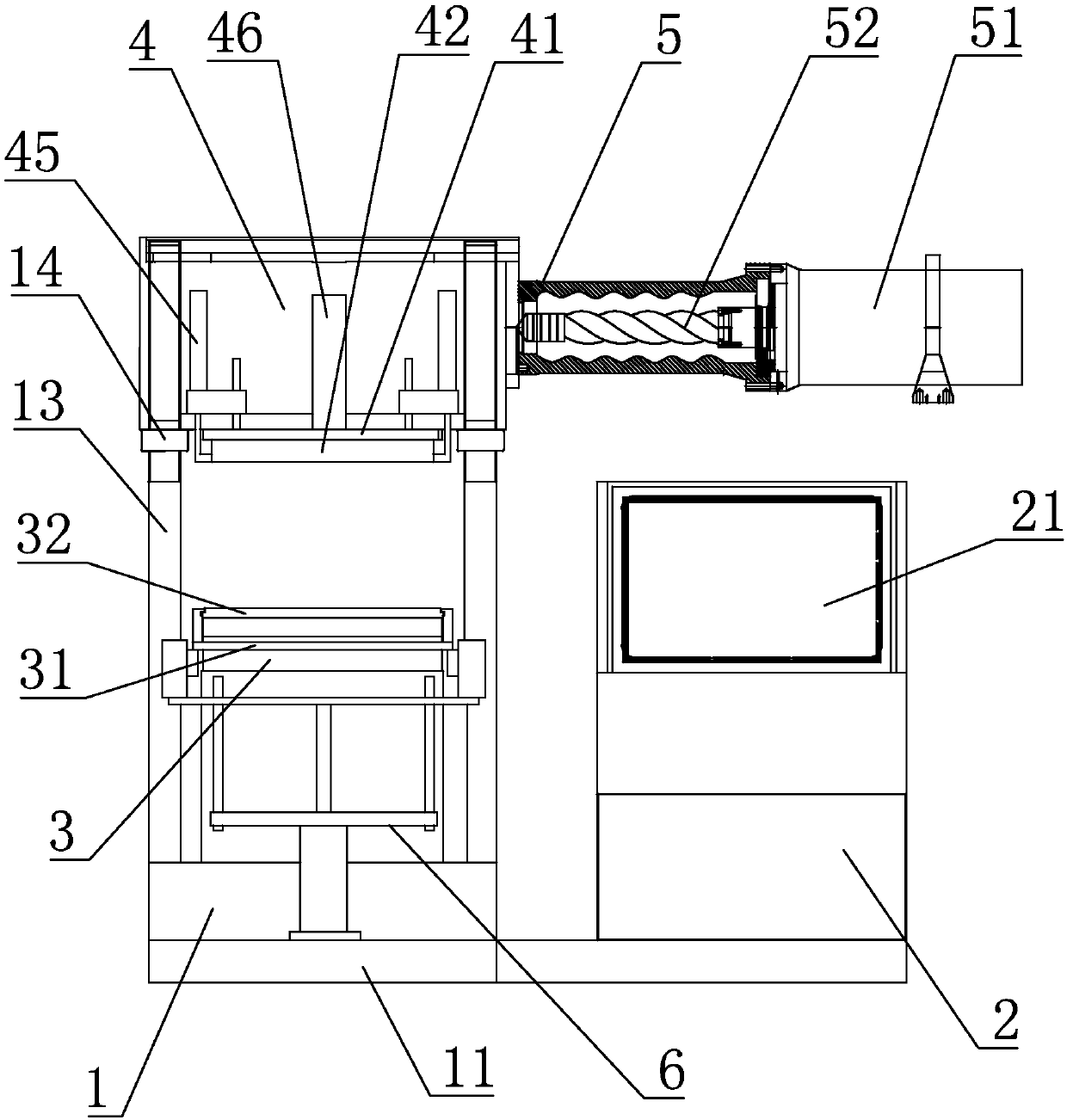

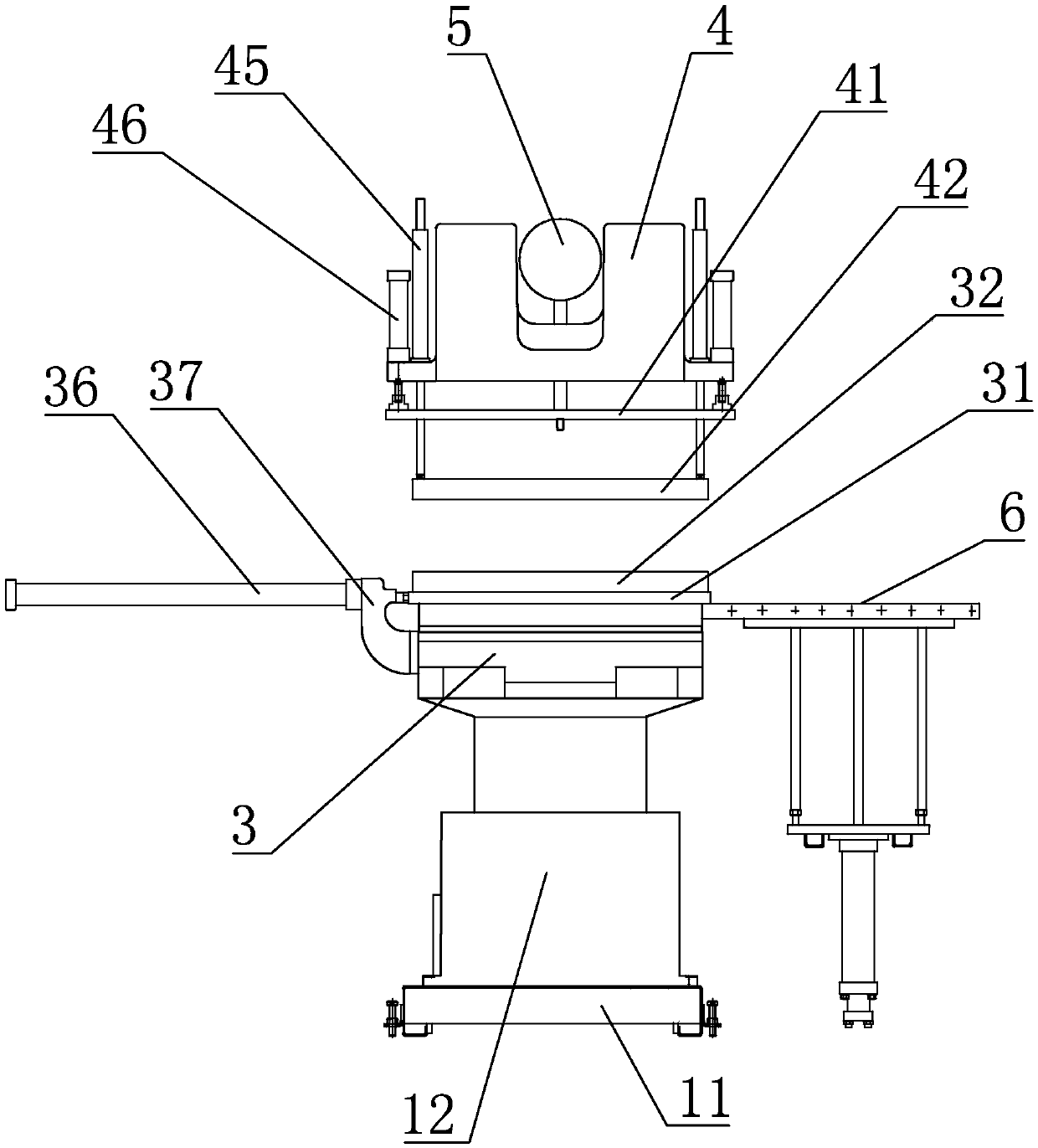

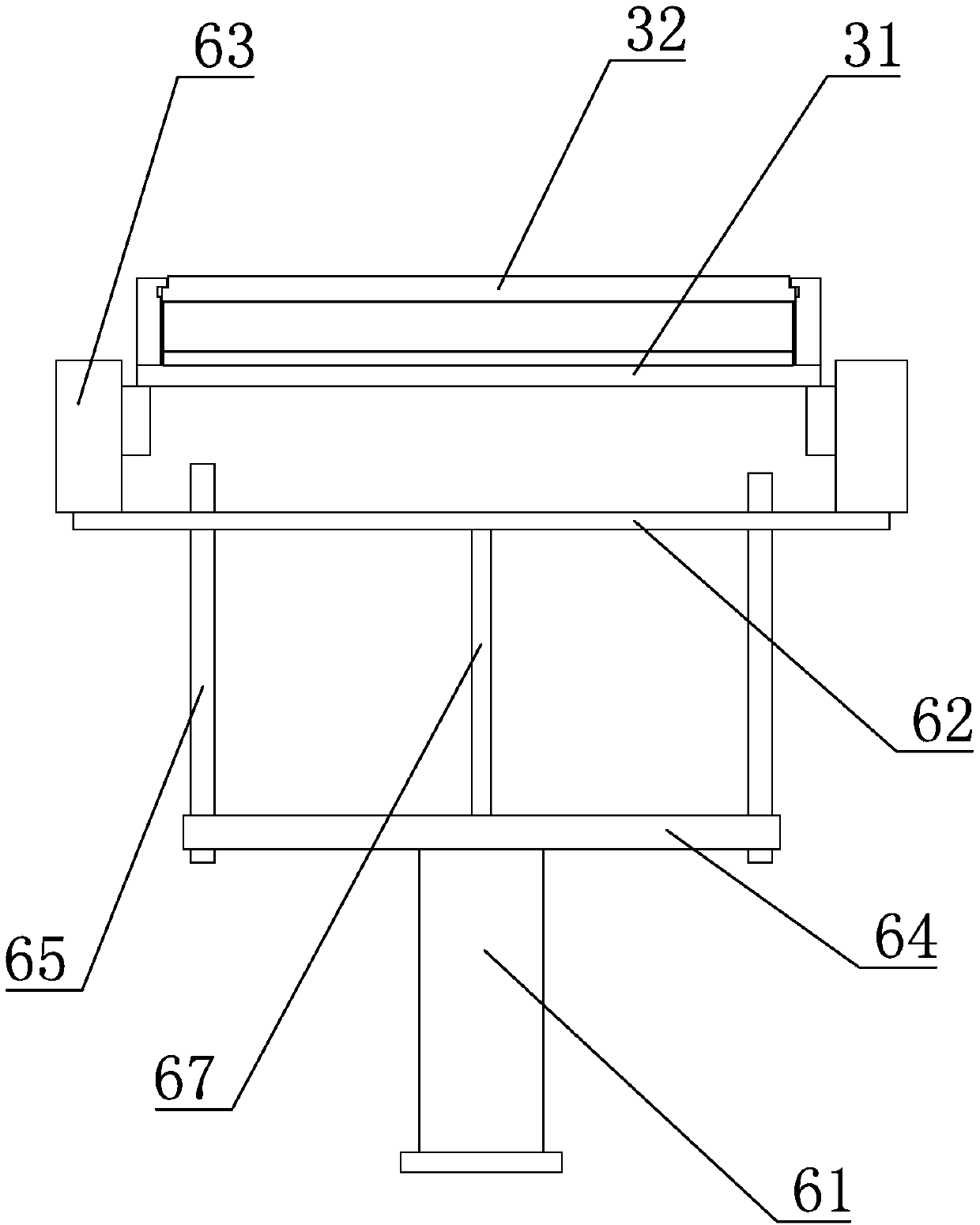

[0020] refer to figure 1 , figure 2 , a thermocompression molding machine with a mold retracting device, comprising a main machine 1 and an operating table 2, the main machine 1 includes a machine base 11 fixed on the ground and a driving device 12, and the operating table 2 is provided with a display panel 21 and The operation buttons are equipped with a PLC control system, and the display panel 21 displays working pictures and status. The machine base 11 is provided with a lower mold base 3 and an injection molding part 4, and the lower mold base 3 is mounted on the machine base 11 so that it can move up and down through a driving device 12. The driving device 12 is electrically connected to the console 2 and controlled by a PLC control system. . The lower mold base 3 is provided with a movable lower mold base plate 31, and the lower mold base plate 31 is fixed with a lower mold 32; the injection molding part 4 is fixed above the lower mold base 3 through the positioning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com