Cylinder molding part sandwiched sizing system device

A system device and sandwich technology, applied in the direction of paper, can solve the problems of paper delamination, low ring crush strength, low paper price, low ring crush strength, etc., to reduce equipment cost investment, improve product grade, and strengthen integration force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

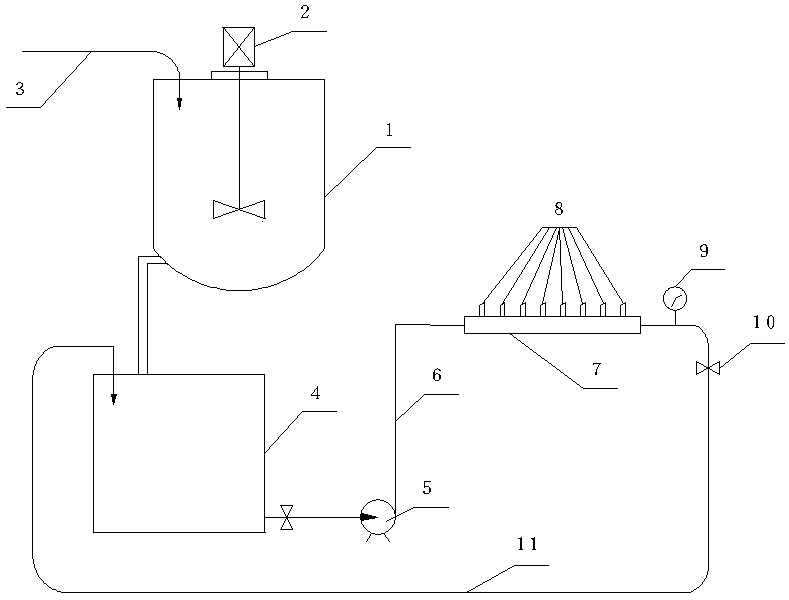

[0011] The concrete structure of the sandwich sizing system device of the rotary screen part of the present invention is as follows: first, a dissolving tank 1 is installed at a height of 1.5 meters from the ground, and a cycloidal pinwheel stirring device 2 is installed in the dissolving tank 1, and a clear water pipeline 3 is introduced into the upper part of the dissolving tank 1. The bottom of the dissolving tank 1 is provided with a gluing tank 4 communicating with it through a pipeline. The discharge port at the bottom of the glue tank 4 is connected to the suction port of the glue pump 5, the discharge port of the glue pump 5 is connected to the sprayer 7 by a high-strength pressure-resistant rubber hose 6, and the tail of the sprayer 7 is equipped with a pressure gauge 9, which can be According to the data read by the pressure gauge, the pressure is controlled and the glue concentration can be controlled according to different quality requirements. The glue concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com