Mold for water dropper forming

A mold and dripper technology, which is applied in the field of dripper molding molds, can solve problems such as increased workload, uneven heating of molds, and influence on mold closing, so as to save mold costs, reduce material costs, and avoid blockage of flow channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

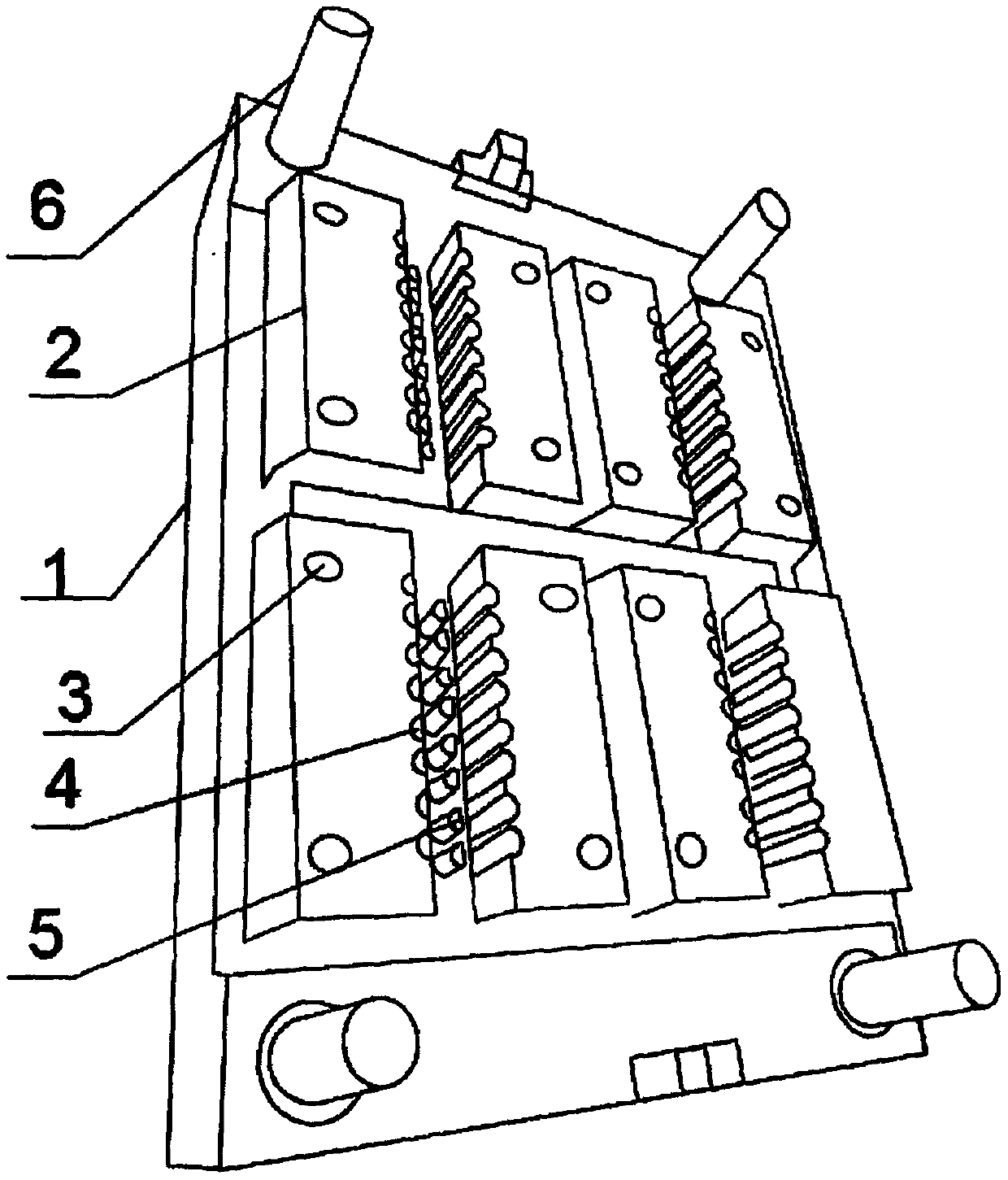

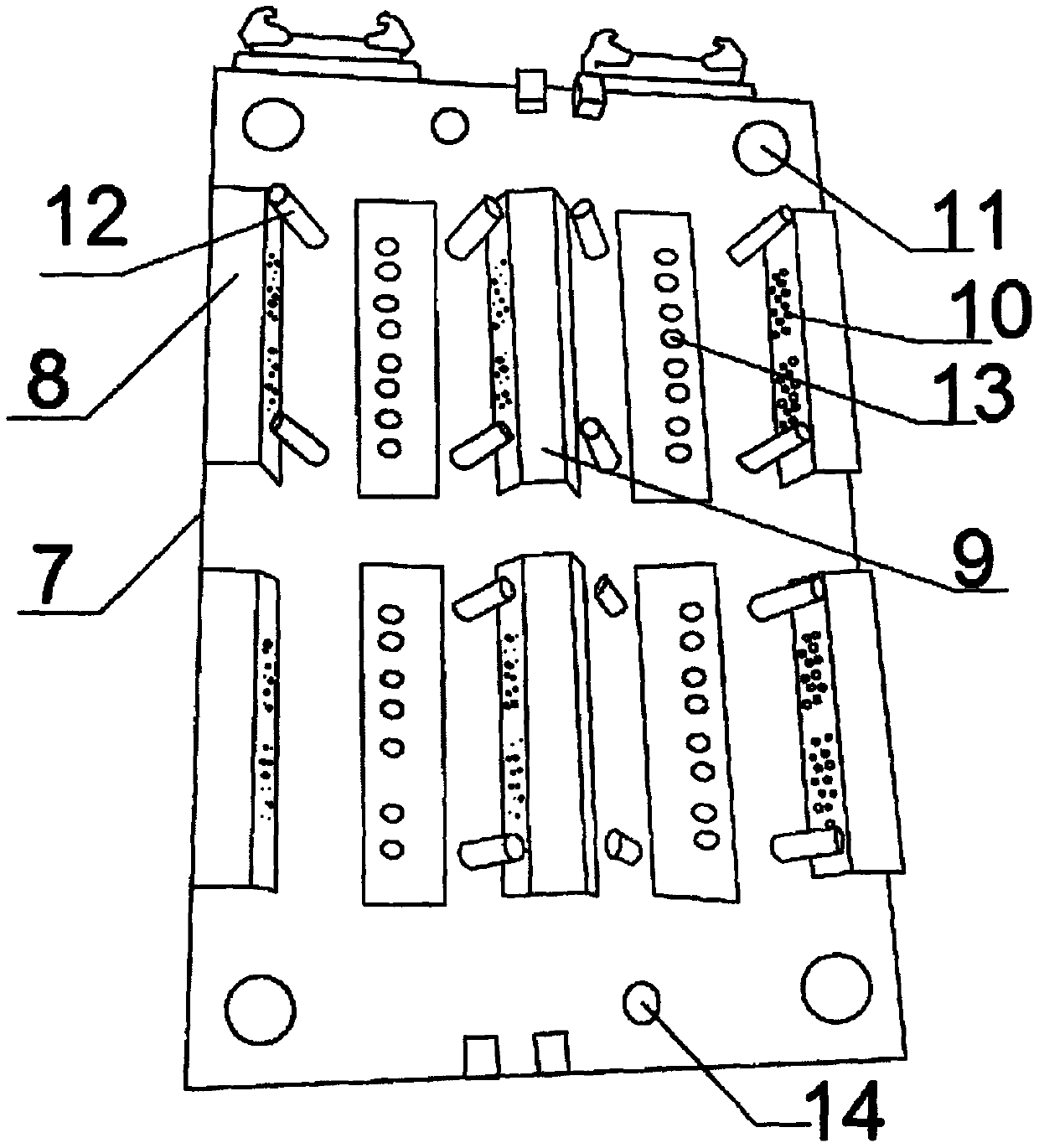

[0021] Such as figure 1 , 2 As shown, a mold for dripper molding of the present invention includes a mold A main body and a mold B main body that can be fastened together, and the mold A main body includes A base 1 and four groups that are independent and protrudingly installed on the A base. The mold core 2 above 1, four groups of mold cores 2 are arranged in two rows, and each row has two groups of mold cores 2, and each group of mold cores 2 includes two rectangular cores spaced side by side, and the two cores are opposite to each other. There are 8 dripper cavities 4 with a semicircular cross-section and vertical penetration on the sides, and the dripper cavities 4 on the two sides are opposite to each other and between each two opposing dripper cavities 4 A cylindrical core 5 is provided, and each core body is provided with two positioning holes 3, and the four corners of the A base 1 are provided with four positioning columns 6; the B mold body includes a B base 7 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com