Asymmetric sliding vane type compressor air cylinder molded line design method

A design method and sliding vane technology, applied in mechanical equipment, rotary piston machinery, rotary piston/oscillating piston pump components, etc., can solve the problems of small pressure ratio of sliding vane compressors, and achieve impact suppression. , the effect of improving the stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

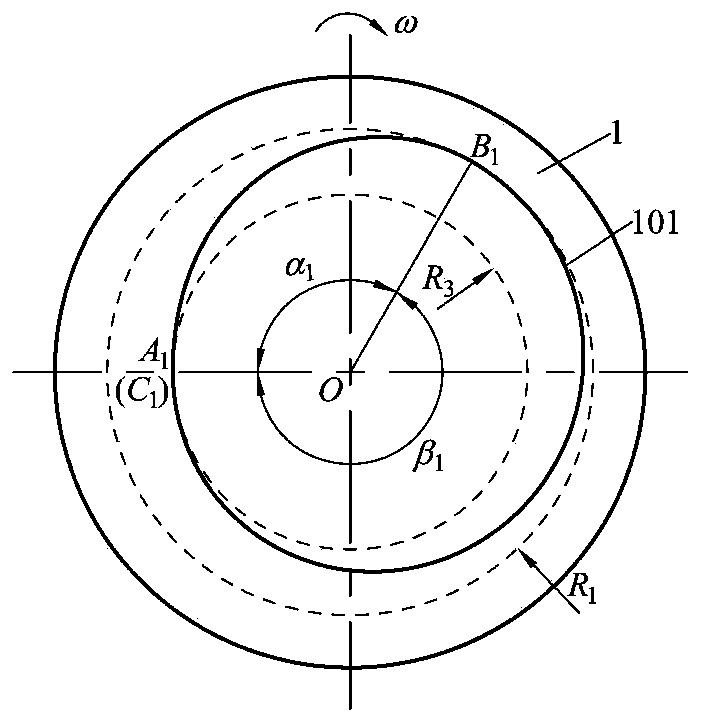

[0040] like figure 1 As shown, when n=1, the cylinder (1) is a single-chamber structure; A on the single-chamber cylinder profile (101) 1 Point and C 1 The points coincide; A exists on the single-cavity cylinder profile (101) 1 , B 1 Two special points, A 1 The point is the closest point on the profile line (101) of the single-cavity cylinder to the center of rotation O, which is located with the center of rotation O as the center of the circle, and the radius of rotation is R 3 on the base circle; B 1 The point is the farthest point on the profile line (101) of the single-cavity cylinder from the center of rotation O, located at the center of the circle with the center of rotation O as the center, and the radius of rotation is R 1 on the top circle of ; go clockwise from A 1 point to B 1 The point is the suction section curve A of the single cavity cylinder profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com