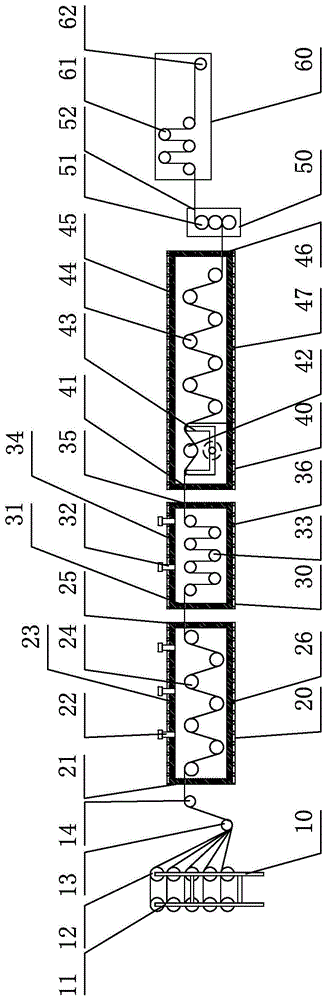

Melt feeding device, continuous fiber reinforced thermoplastic impregnated belt molding device and method

A technology of enhancing thermoplastic and feeding device, applied in the direction of coating, can solve the problem of long flow channel, achieve the effect of simple structure, reduce melt flow resistance and heating time, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

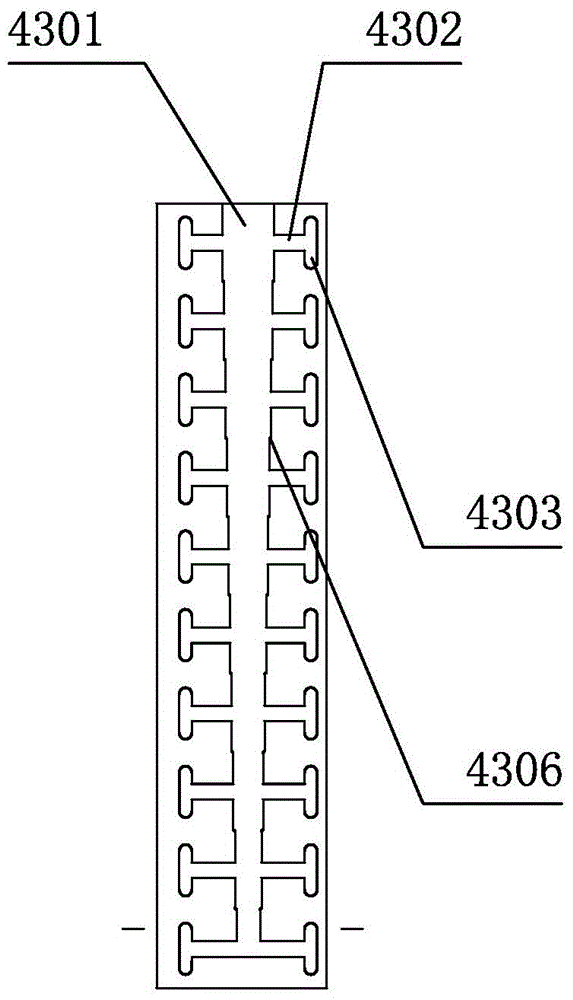

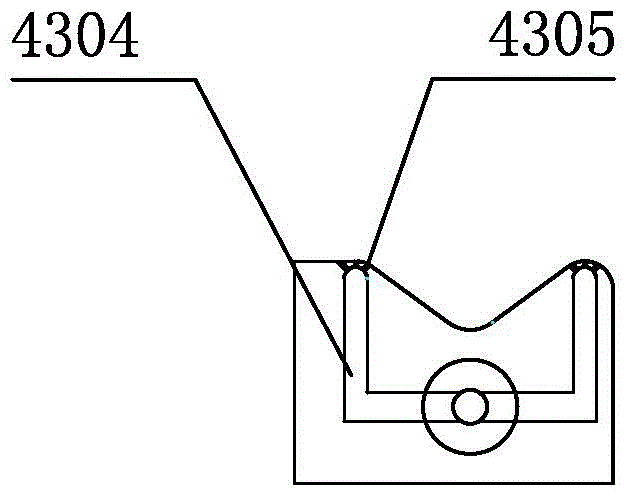

[0035] Such as Figure 2~3 As shown, the melt feeding device 43 includes a main channel 4301, and the main channel 4301 communicates with the first-level sub-runner 4302, the second-level sub-runner 4303, and the third-level sub-runner 4304 in turn, and the first-level sub-runner 4301 is separated from the main channel 4301. Distributed in parallel along the main channel 4301. The diameter of the main channel 4301 gradually becomes smaller along the melt flow direction, and the diameter change mode can be gradual or gradually decreasing. In this embodiment, the main channel 4301 is divided into multiple sections, and the diameter of each section decreases. The diameter of the latter section of the direction decreases by 2% to 20% relative to the diameter of the previous section, and the transition between adjacent sections is connected by a transition c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com