A low-resistance enhanced heat transfer structure based on nano-superwetting interface

A technology to strengthen heat transfer and interface, which is applied in the direction of modification by conduction heat transfer, indirect heat exchanger, heat exchanger type, etc., can solve the problems of high flow resistance, high power consumption, etc. The critical heat flux density and the effect of improving the surface heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

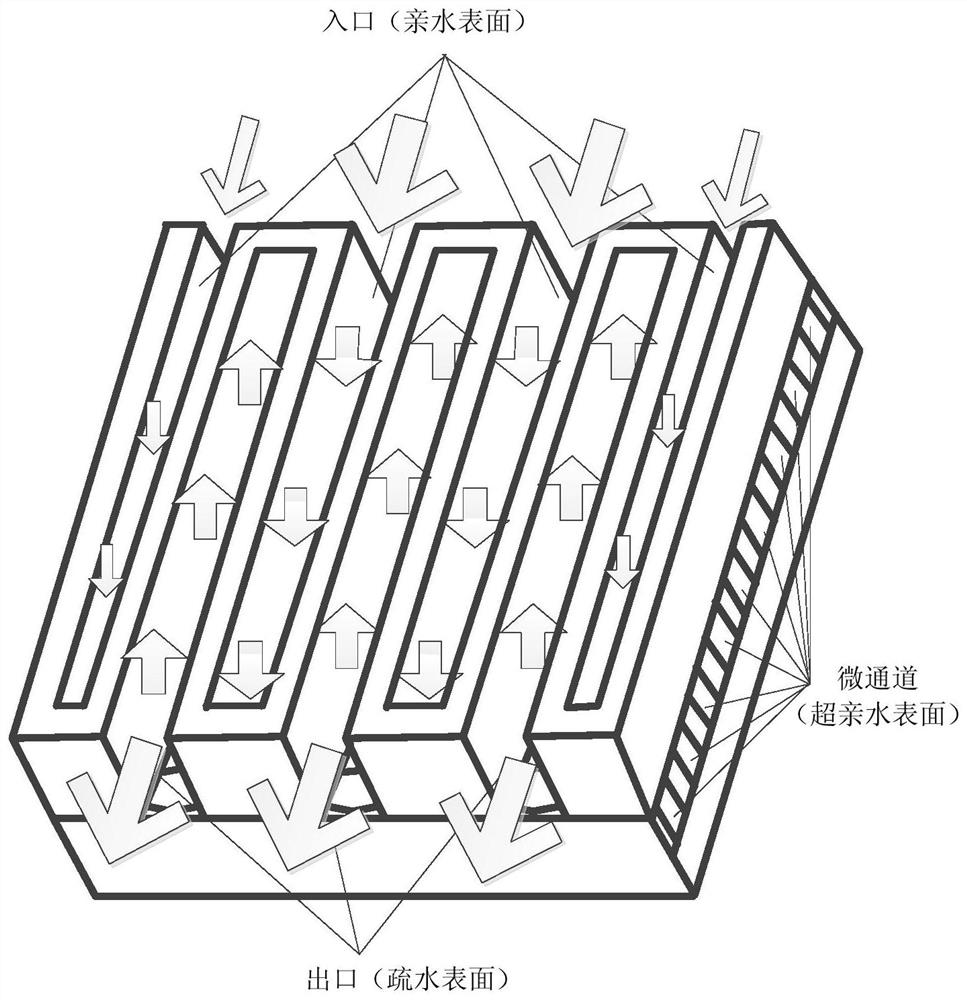

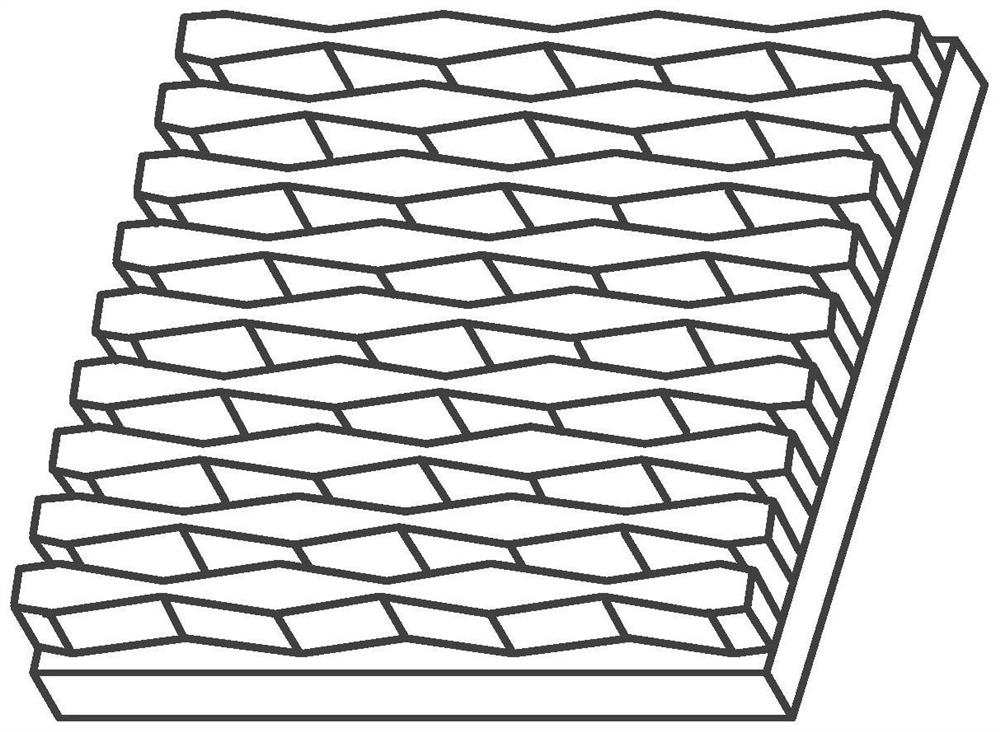

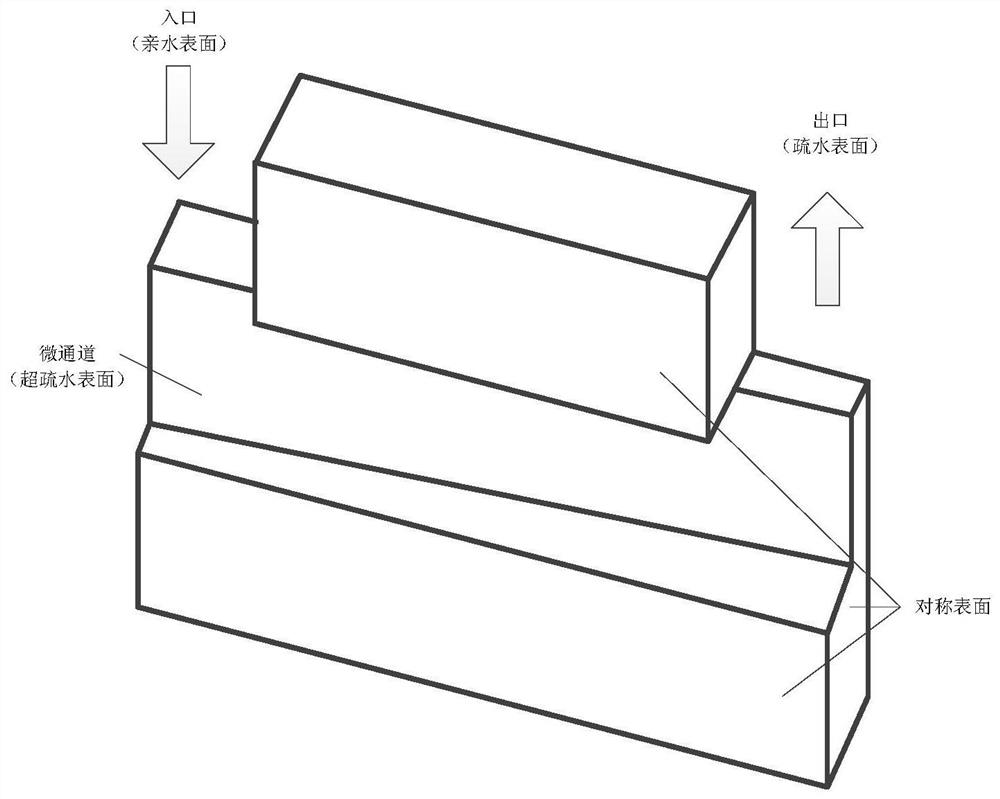

[0030] The significant increase in the specific surface area brought about by the tiny channels can greatly enhance the single-phase and two-phase convective heat transfer capabilities, but at the same time it will also generate greater flow resistance, and the contradiction between heat transfer enhancement and resistance increase has not been effectively resolved. In addition, interfacial wettability refers to the wetting of solids by liquids and is an important feature of solid surfaces. As an important factor affecting boiling heat transfer, interfacial wettability has been a hot spot in boiling heat transfer enhancement technology for many years. The interface wettability has different effects on boiling heat transfer: on the one hand, the hydrophilic surface can significantly increase the critical heat flux; on the other hand, the hydrophobicity can significantly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com