Blow molding machine head

A technology of blow molding head and head, which is applied in the field of blow molding on blow molding machines, can solve problems such as increasing production costs, reducing product quality, and thermal oxidation reactions, and achieves uniform distribution, reduced processing costs, and reduced material degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

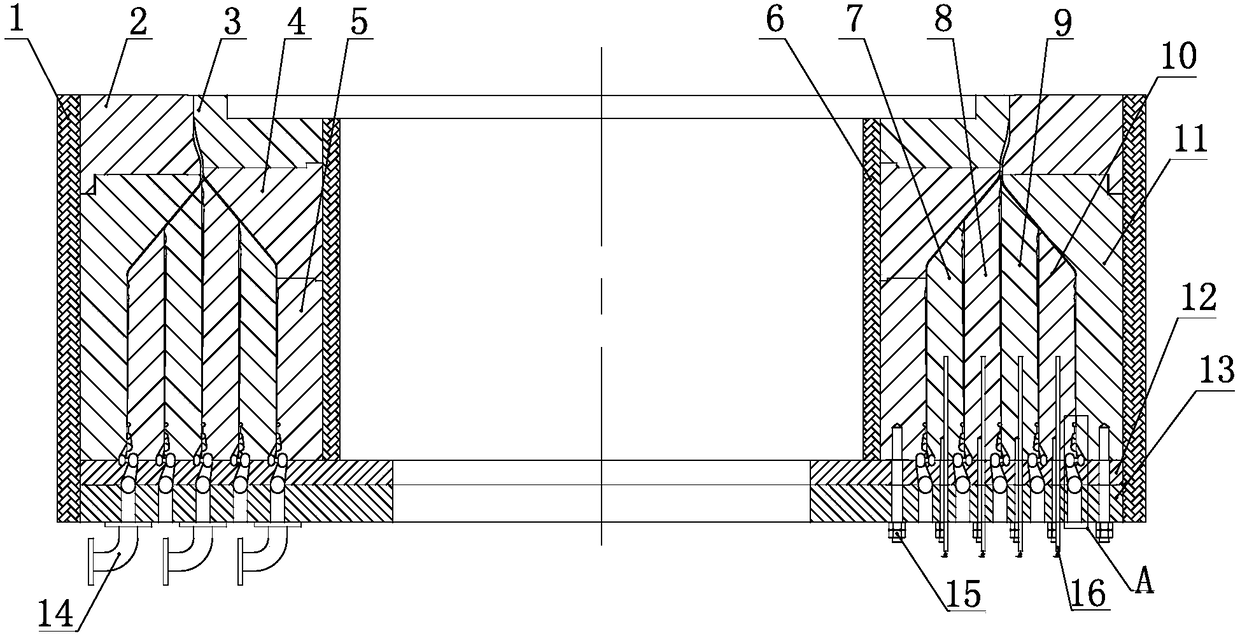

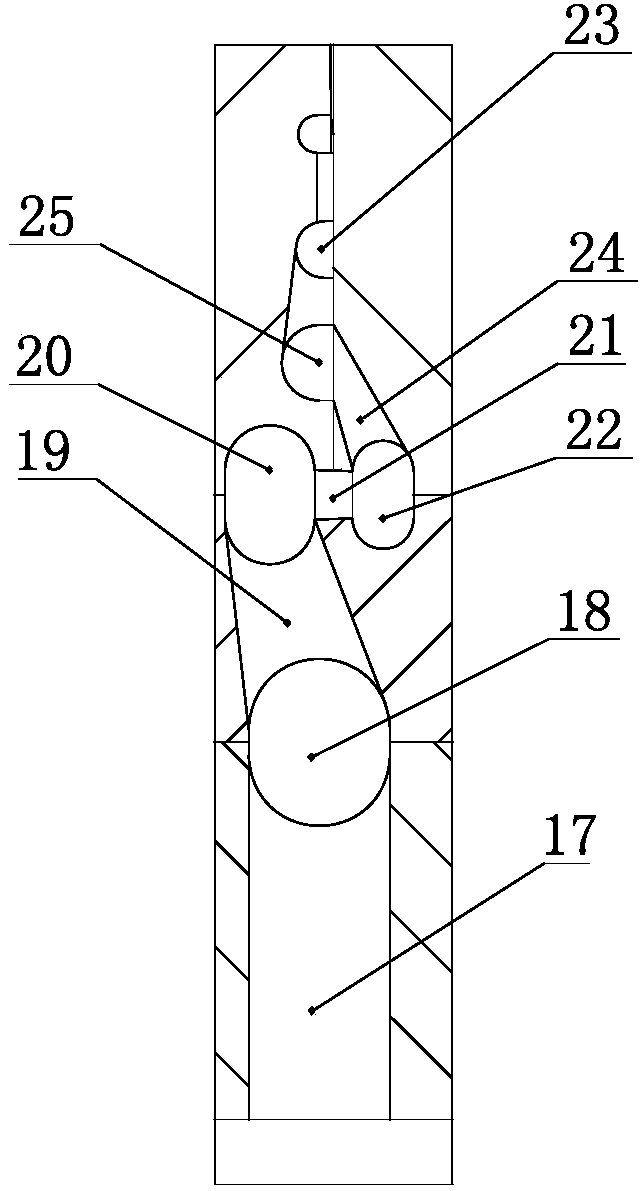

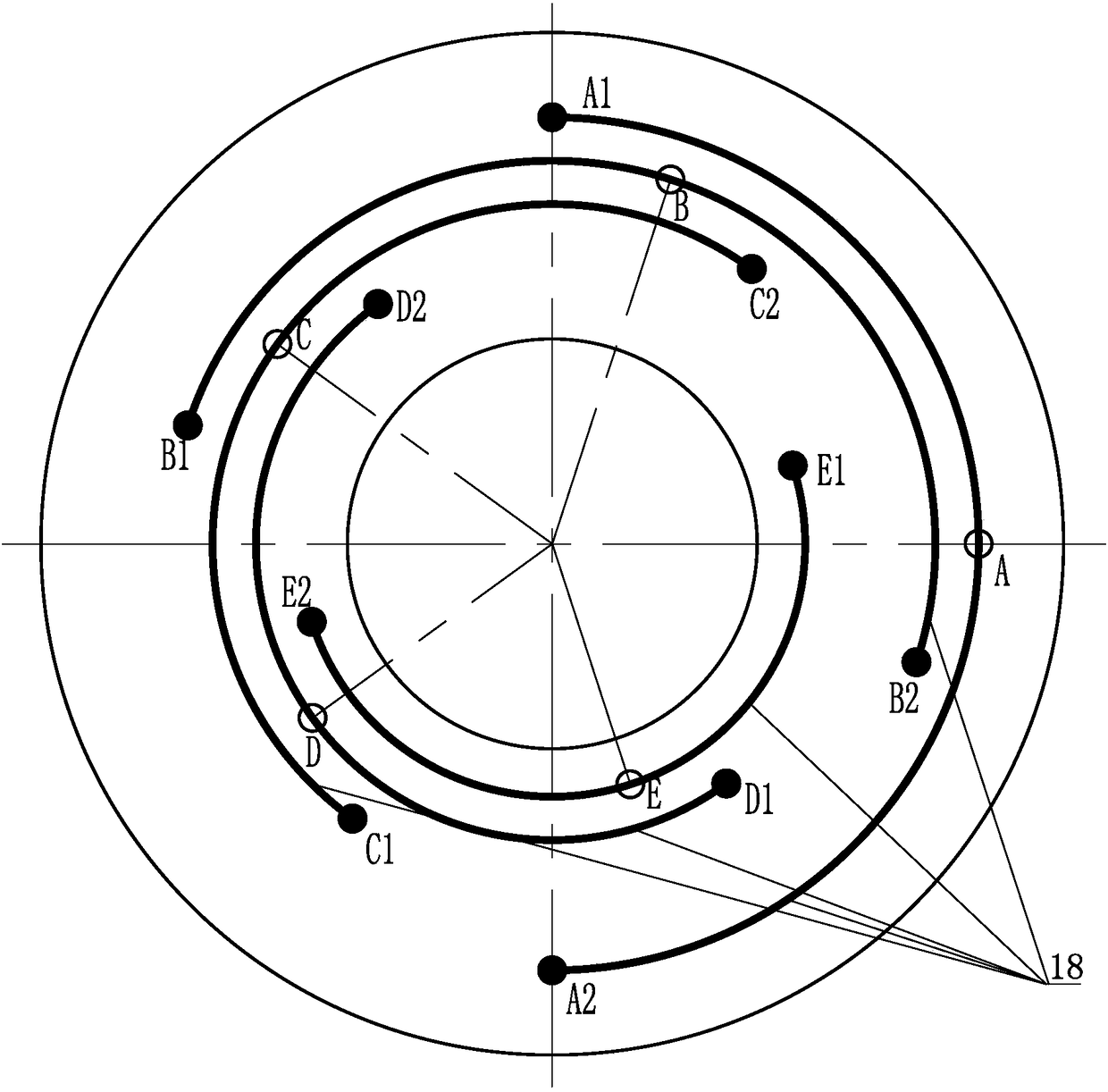

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as Figure 1 to Figure 7 As shown, the blow molding machine head of the present invention includes an annular machine head body 11, and five layers of annular helicoids are arranged inside the machine head body 11, which are respectively inner helix I5, inner helix II7, middle helix 8, outer helix II9 and Outer helix I10, the upper part of the helix has a lower die 4, the upper part of the lower die 4 has an upper die 3, the outer side of the upper die 3 is an adjustment ring 2, and a spiral channel 23 is formed between two adjacent helicoids, and the bottom of the spiral channel 23 is set Splitter plate, the bottom of the splitter plate is evenly distributed with feeding ports along the circumferential direction of the spiral channel 23, and each feeding port is set corresponding to one of the spiral channels 23, and the inside of the splitter plate is vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com