Energy-saving back-filling mechanism

A technology for ejecting plates and runners, which is applied in the field of plastic molds, can solve the problems of high mold processing costs, complex mold structures, and low production efficiency, and achieve the goals of shortening the molding cycle, shortening the length of runners, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

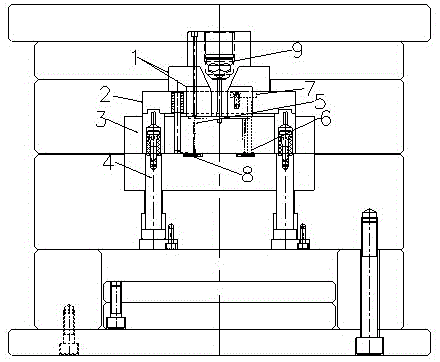

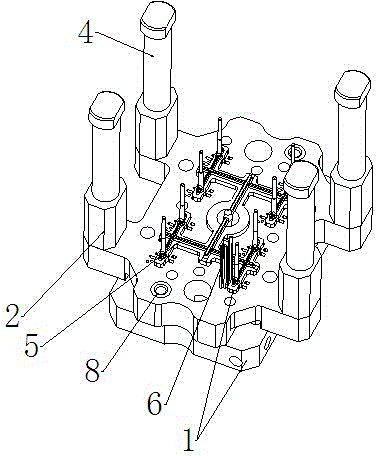

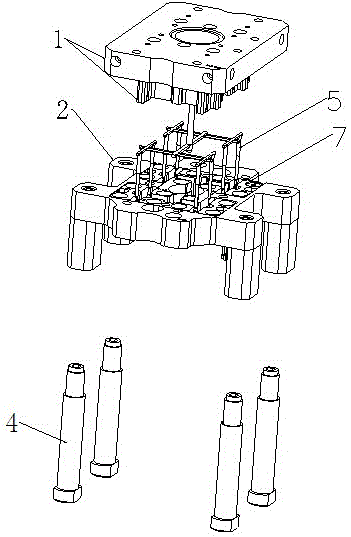

[0016] see Figure 1 to Figure 3 , the embodiment of the present invention includes:

[0017] An energy-saving reverse pouring mechanism, comprising: a runner plate 1, an ejector plate 2, a female mold core 3, a tension rod 4, a runner 5, a thimble 6, a thimble cover plate 7, a guide post guide sleeve 8 and a main filling nozzle 9.

[0018] The runner plate 1, the ejector plate 2, and the female die core 3 are connected sequentially from top to bottom. The upper end of the tension rod 4 passes through the female die core 3 and is connected to the ejector plate 2. In this embodiment, the upper end of the tension rod 4 is equipped with a shutter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com