Comfortable foaming EVA slipper and manufacturing process

A manufacturing process and comfort technology, applied in the application field of polymer materials, can solve the problems of reduced comfort, small spray volume, and weak comfort effect, and achieve the effect of strong comfort and improved ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

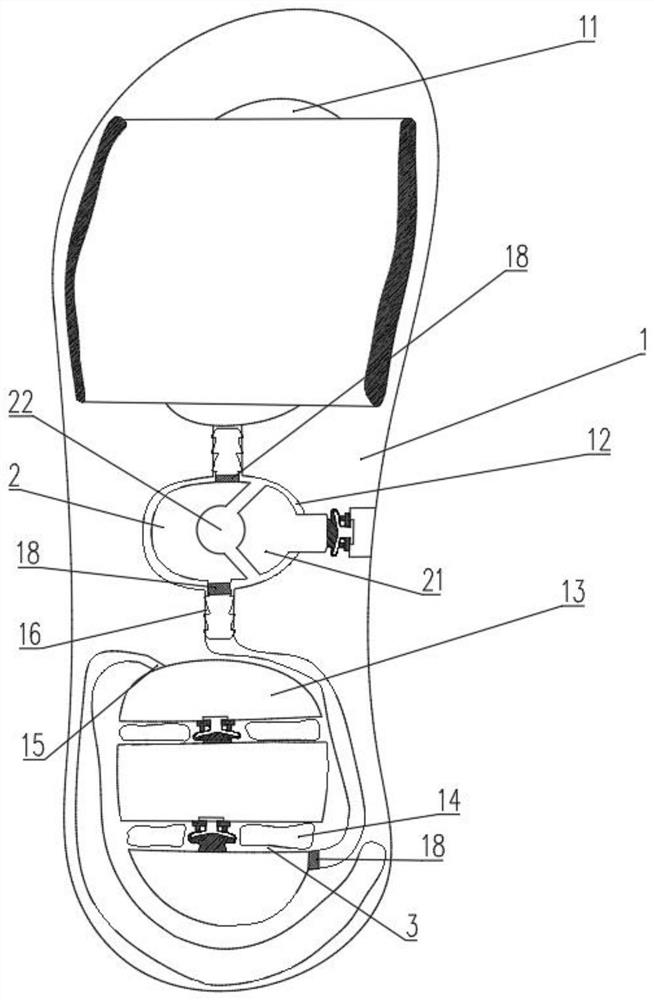

[0035] Embodiment 1: relates to the manufacture of a kind of sole 1 of above-mentioned slipper, a kind of manufacturing process of comfort foaming EVA slipper:

[0036] (1) Soak the once-foamed EVA lower bottom and upper bottom in UV treatment agent for 2~5 minutes, and then transport them to the ultraviolet irradiation machine and X-ray irradiation machine for irradiation, so that the polarity of the foamed EVA sole 1 Reinforced, easy to glue;

[0037](2) Apply glue to the part of the shoe upper that needs to be bonded, apply glue to the part where the lower bottom needs to be bonded to the upper bottom, and apply glue to the adhesive surface of the upper bottom that is directly opposite the sealed air bag 14 of the lower bottom, and then apply glue The glued upper, lower bottom and upper bottom are transported to the first baking machine and baked at 50~60°C;

[0038] (3) Then, the shoe sole 1 that has been glued once is applied to the glued part of step (2) for the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com