Flow box

A technology of headbox and pulp distributing, which is applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc. It can solve the problems of low paper evenness, unstable pulp flow, large cross flow, etc., and achieve stable pulp flow, Improve uniformity and reduce cross flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, which are explanations of the present invention rather than limitations.

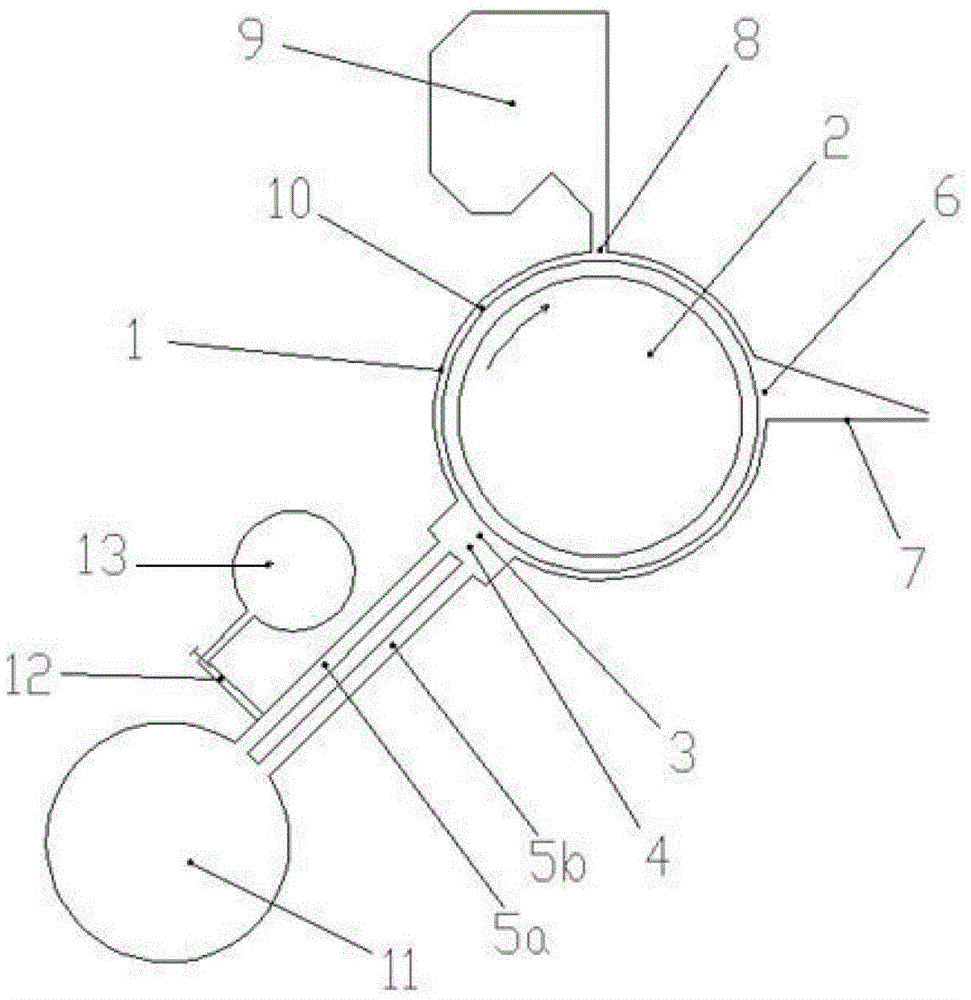

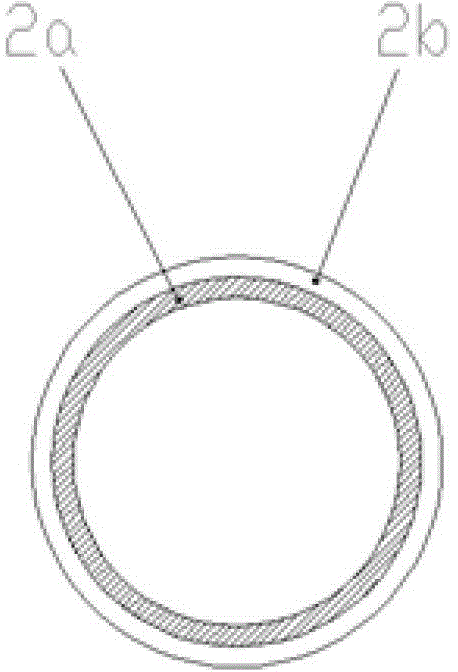

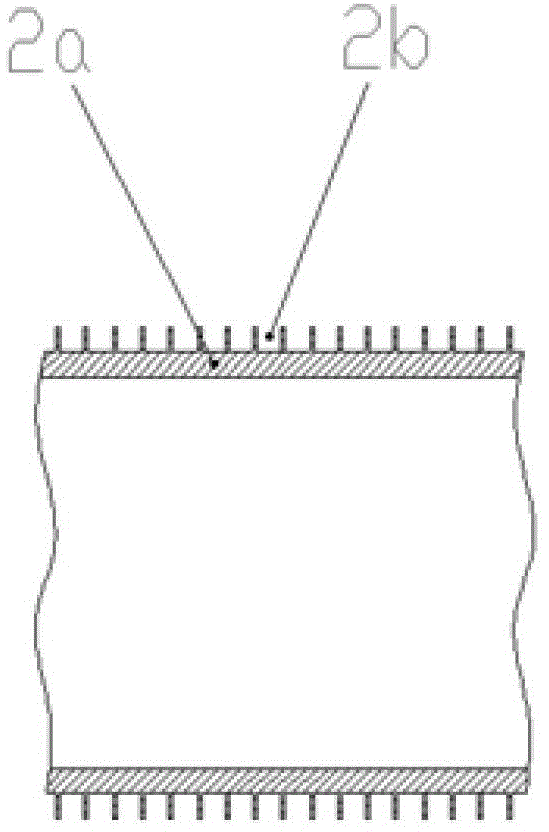

[0028] see figure 1 , the headbox of the present invention comprises a cylindrical housing 1 placed horizontally, and a cylindrical roller 2 with a diameter smaller than the diameter of the cylindrical housing 1 is coaxially sleeved inside the cylindrical housing 1, and the outer surface of the roller 2 is There is a gap 10 between the inner surface of the cylindrical shell 1, the axis of the roller 2 coincides with the axis of the cylindrical shell 1, the roller 2 can rotate around its own axis in the clockwise direction shown by the arrow in the figure, and the roller 2 There are a number of annular grooves 2b on the outer roller surface of the cylindrical housing 1, and a slurry inlet 3 is provided at the lower right of the cylindrical shell 1, and an equalization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com