Triple extrusion die head with low center

A three-layer co-extrusion, low-center technology, applied in the field of plastic film manufacturing machinery, can solve the problems of long time required to replace resin or color, reduction of effective height of upper traction, and increase of manufacturing difficulty of extruder, so as to reduce polymer The effect of stock, layer thickness uniformity and overall film thickness improvement, flow distribution and flow rate uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

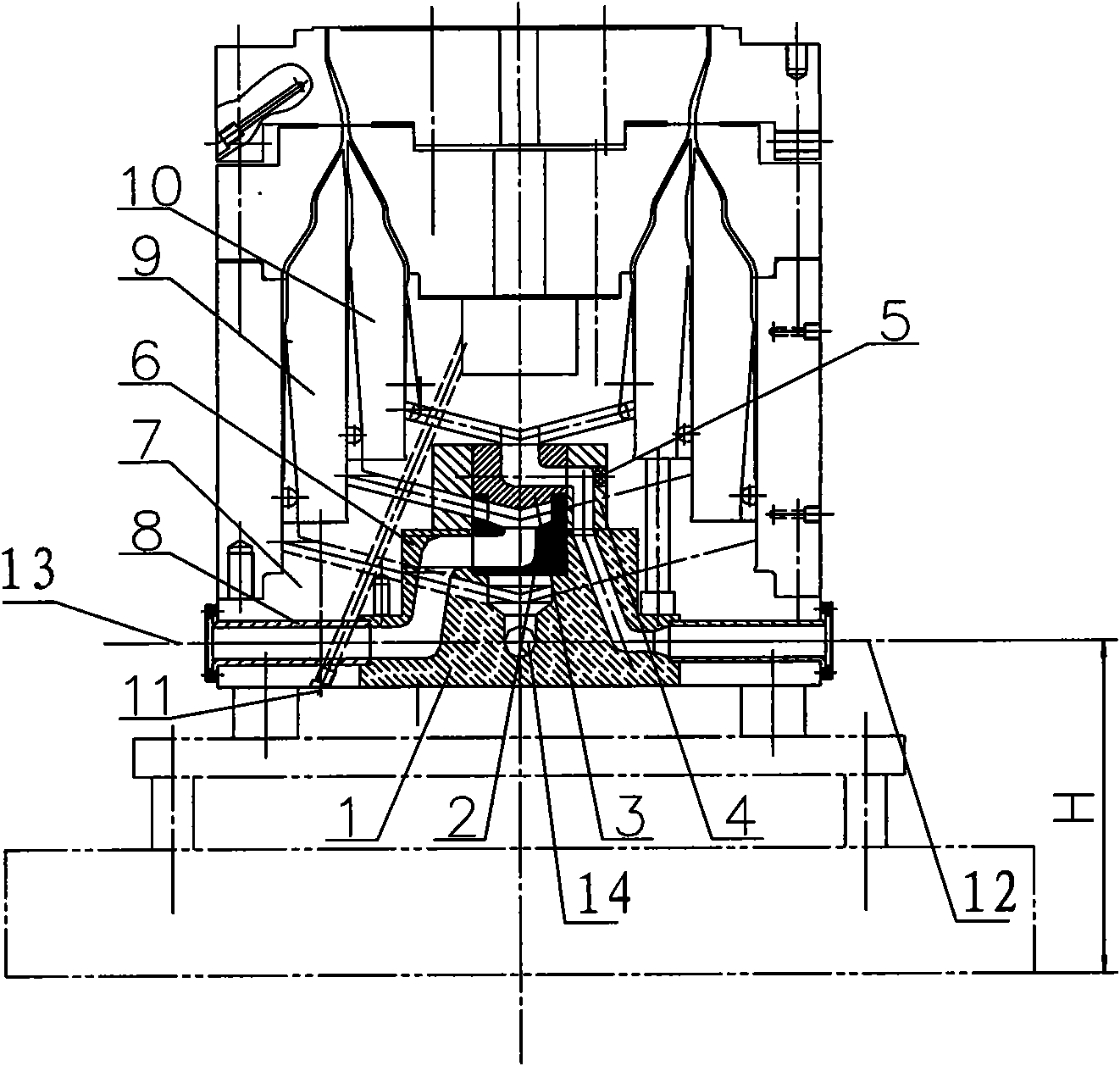

[0013] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only used for illustration. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0014] Referring to the accompanying drawings, it can be seen that a low-center three-layer co-extrusion die head of the present invention, its inner layer feed port 12, middle layer feed port 13, and outer layer feed port 14 are located on the same plane whose center height is H, so Said inner layer feed port 12 is successively connected by the channel in the sealing sleeve 8, the channel on the outer layer sub-fluid 1, the channel formed between the connecting body 4 and the right plug 5, and the channel on the inner layer sub-fluid 3 Formed a channel leading to the inner spiral body 7; the middle layer feed port 13 is sequentially composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com