A water pump rotor forming method

A molding method and technology of water pump rotors, which are applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of low concentricity of water pump rotors, weak resistance to temperature and impact, and difficulty in mold filling. Good mechanical shock, good temperature shock resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

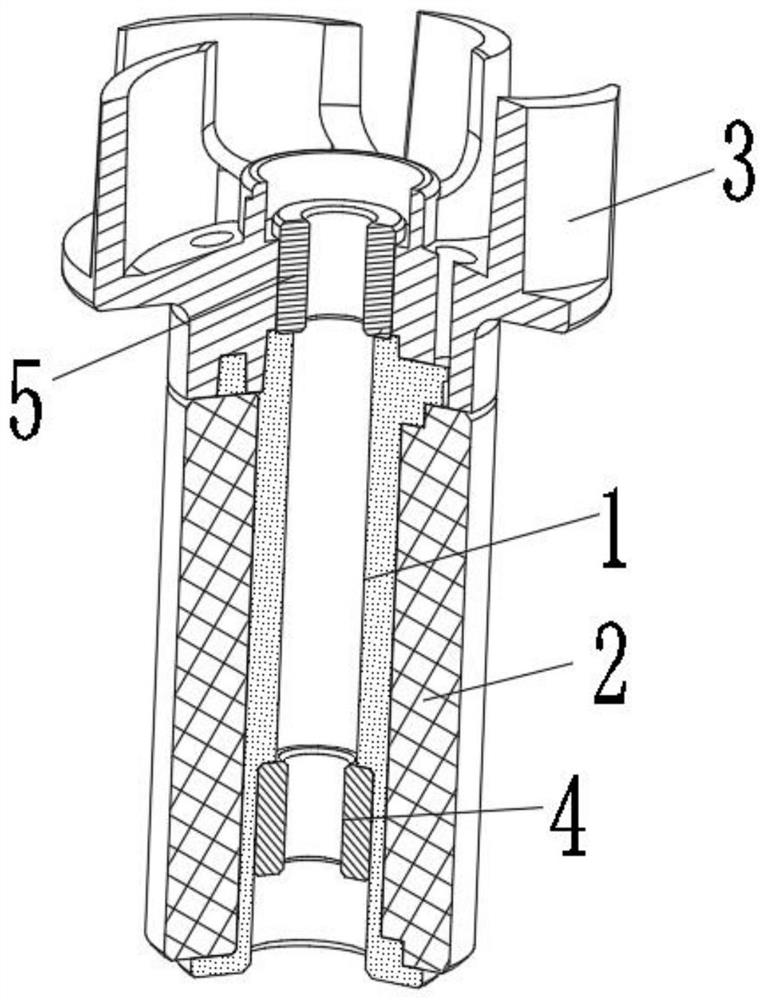

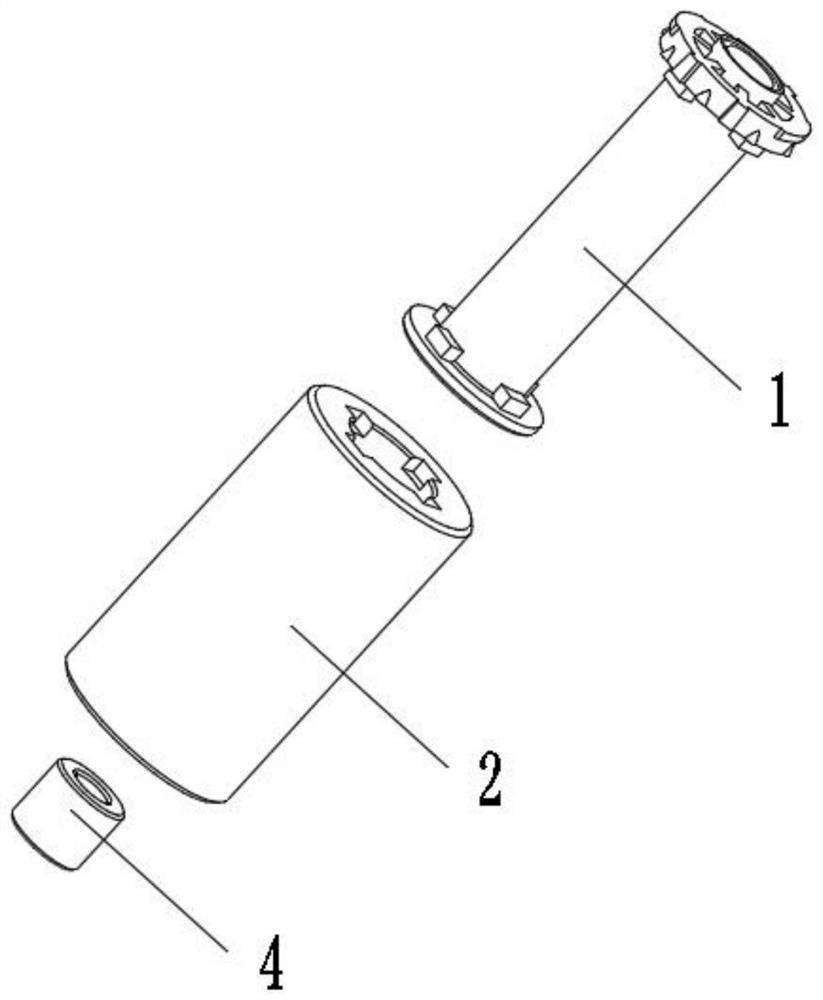

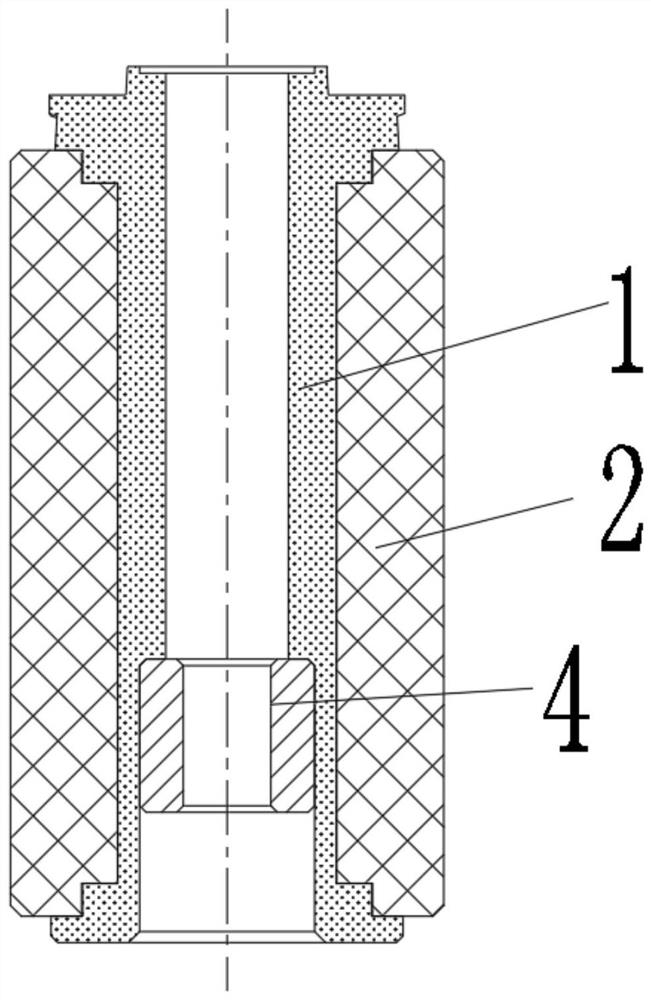

[0016] See attached Figure 1-4 , a method for forming a water pump rotor, comprising a concentrically arranged magnetic ring 2, a long cylindrical rotor frame 1, and an impeller cover 3, the magnetic ring 2 is sleeved on the outer surface of the rotor frame 1, and the impeller cover 3 is set on the rotor frame 1, the inner cavity of the rotor frame 1 is provided with a first bearing 4, and the center hole of the impeller cover 3 is provided with a second bearing 5, which is molded in two steps, the first time During the second molding, the impeller cover 3 is formed by injection molding on the semi-finished product, and the second bearing 5 is coated with glue on the impeller In the cover 3, the two bearings are positioned with the same pin when they are molded twice, which can better ensure the concentricity. After injection molding, there is no need for reaming, which saves man-hours. The material cost of the two short bearings is low, and the bearings are overmolded. , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com