Horizontal solid-liquid dual-purpose composite insulator former

A technology for composite insulators and molding machines, which is applied in the direction of insulators, electrical components, circuits, etc., to achieve the effects of improving internal quality, saving rubber materials, and facilitating exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

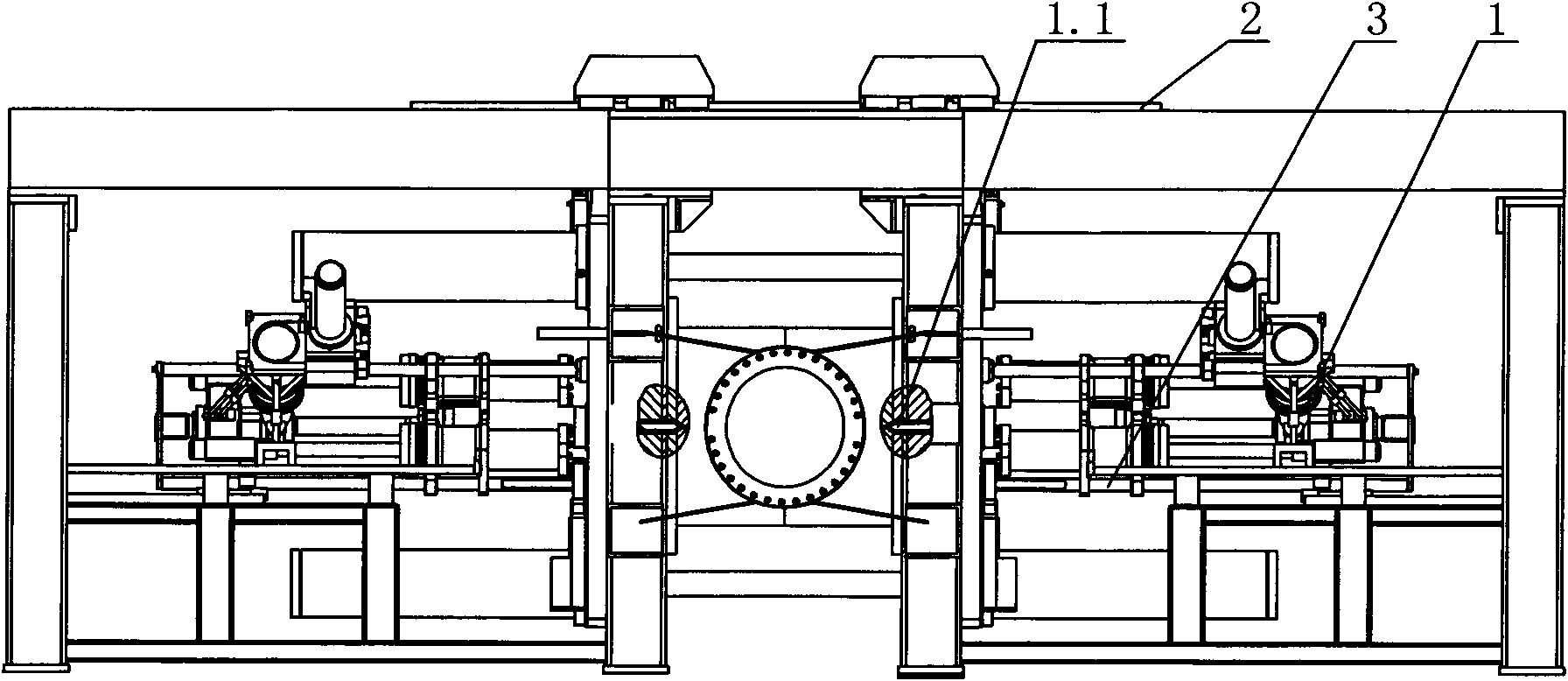

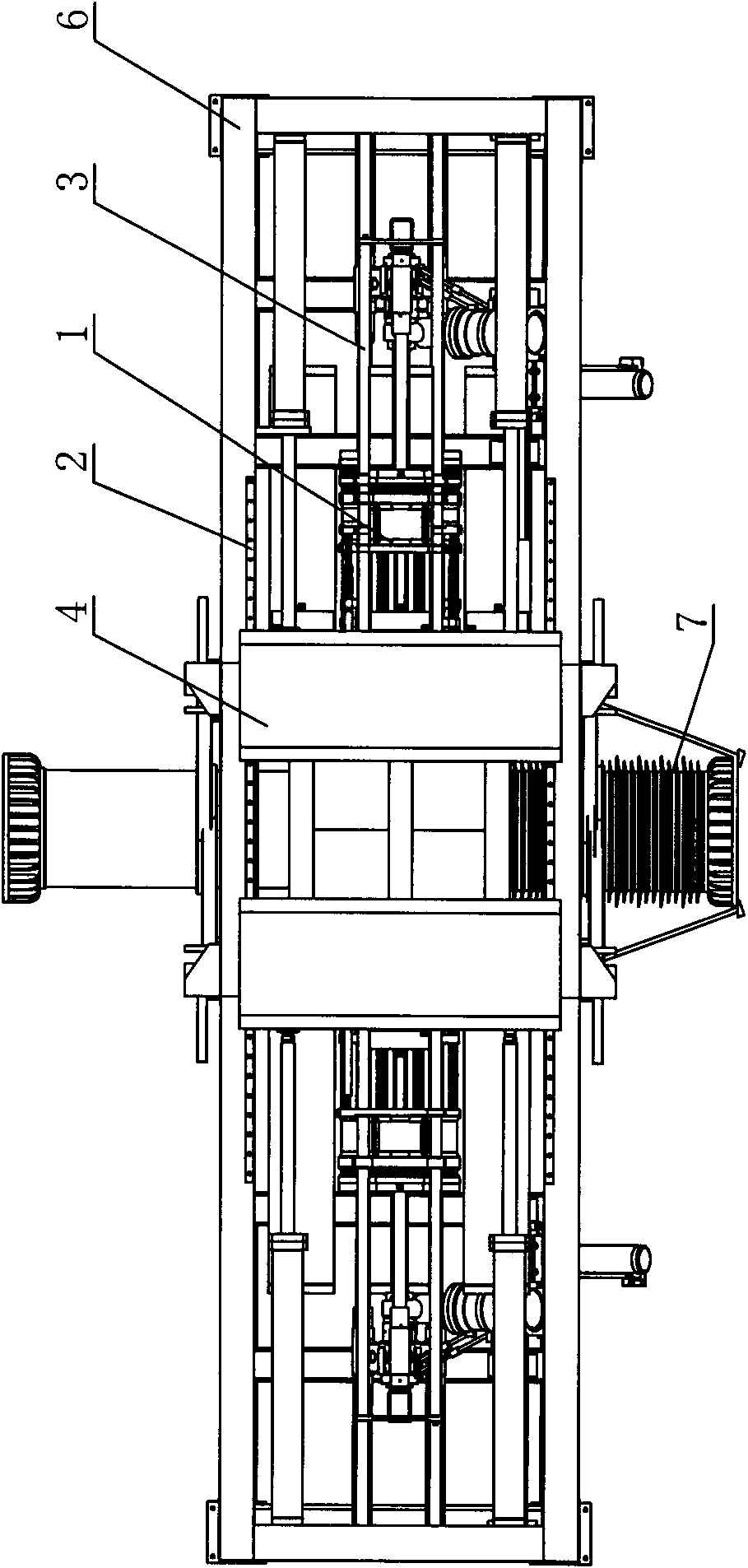

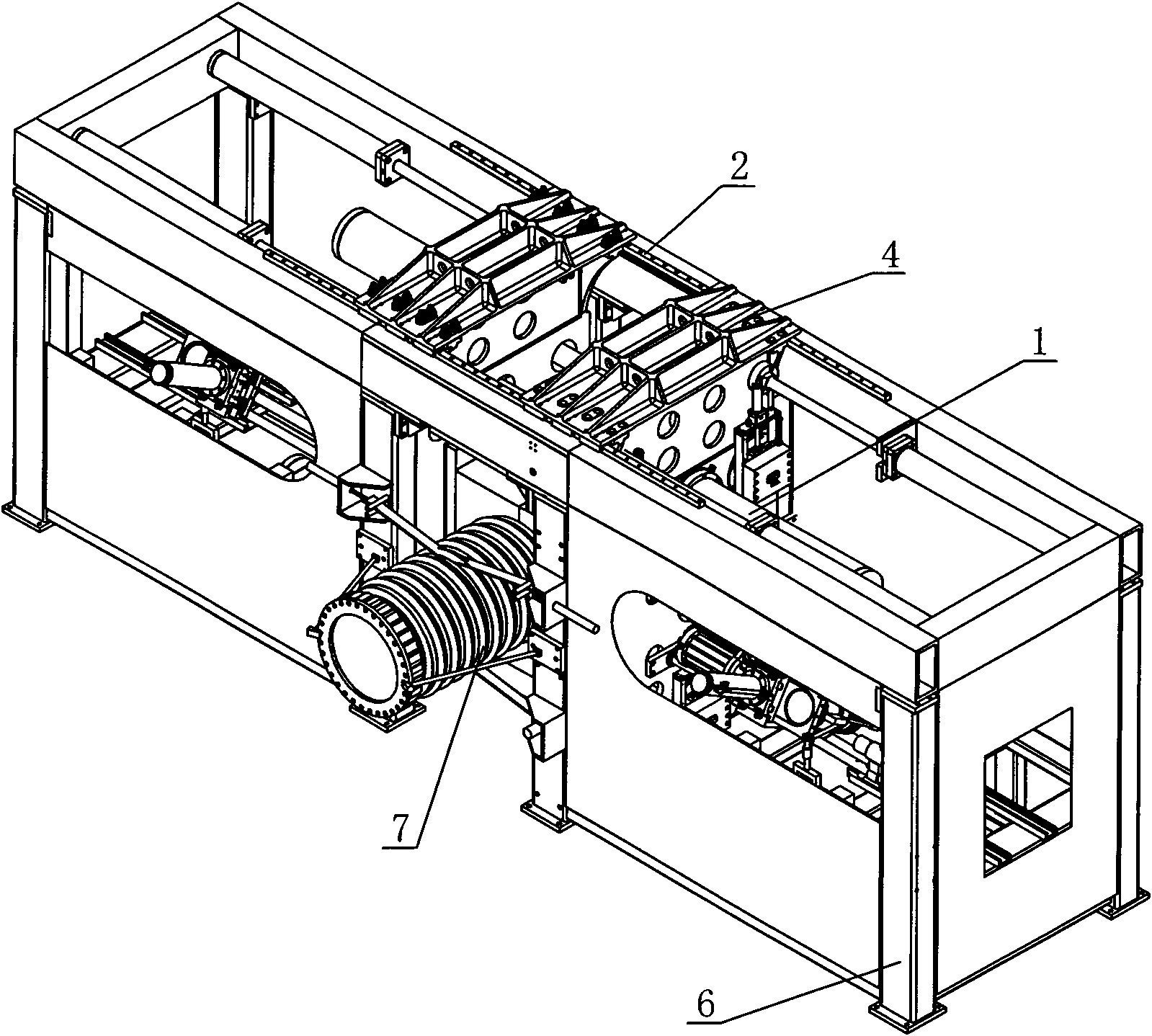

[0019] see Figure 1-Figure 3 , the horizontal solid-liquid dual-purpose composite insulator molding machine includes a clamping frame 6 and an injection plasticizing device 1, the injection end of the injection plasticizing device is connected to the movable template 4 of the fixed mold, and the mold clamping frame 6 Two sets of horizontally slidable injection plasticizing devices 1 are horizontally arranged, and the injection ends thereof are all facing the inside of the clamping frame 6 .

[0020] Two ends of the clamping frame 6 are provided with a set of injection plasticizing devices 1 respectively, and two movable templates 4 are respectively connected with the left mold and the right mold of the mould; There are two sets of injection platform moving slide rails 3 horizontally arranged inside the clamping frame 6 corresponding to the two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com