Automatic hydraulic mudjacking machine

A hydraulic and automatic technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of slow discharge, time-consuming and laborious, etc., and achieve the effect of simplifying the grouting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

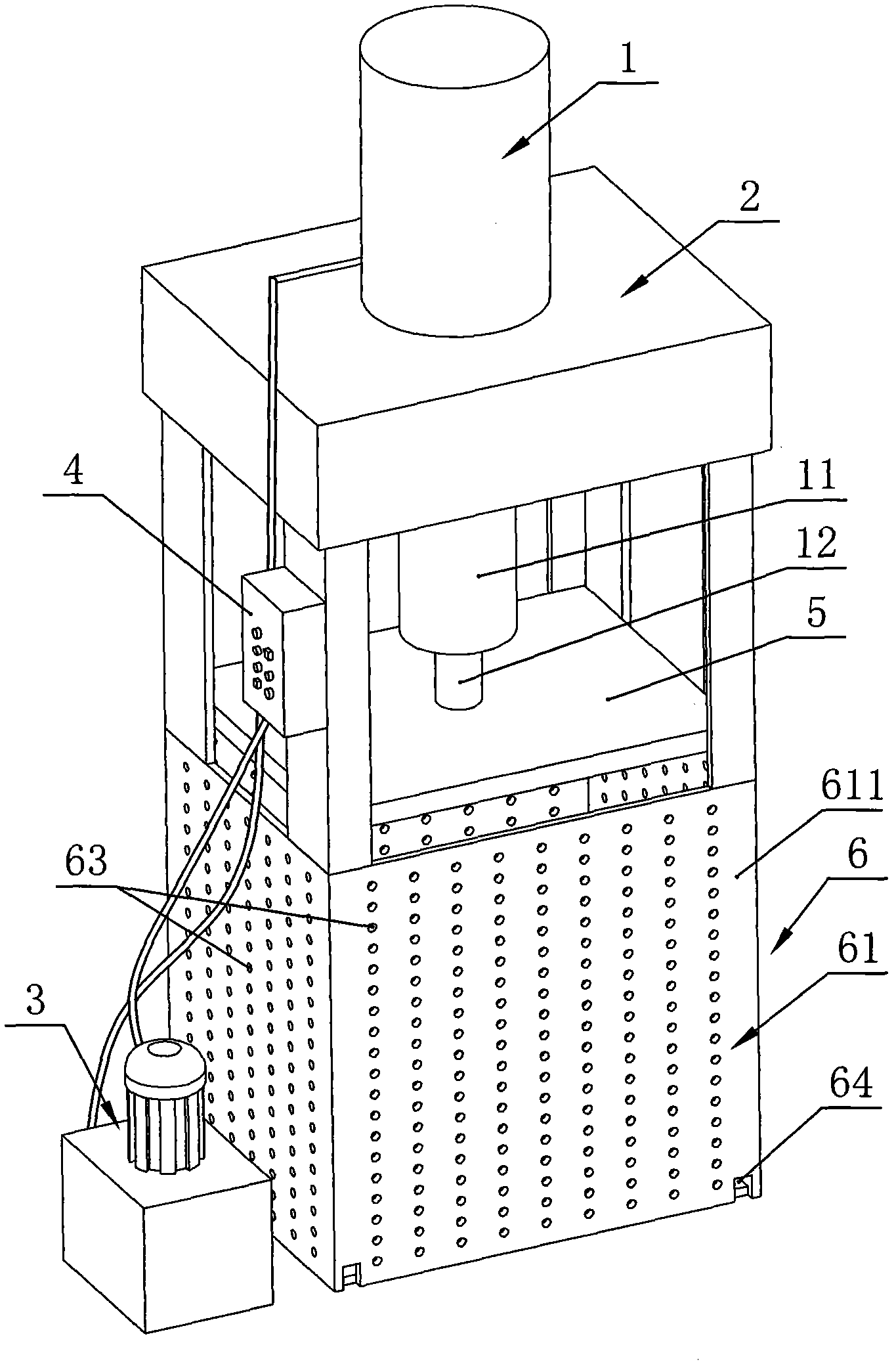

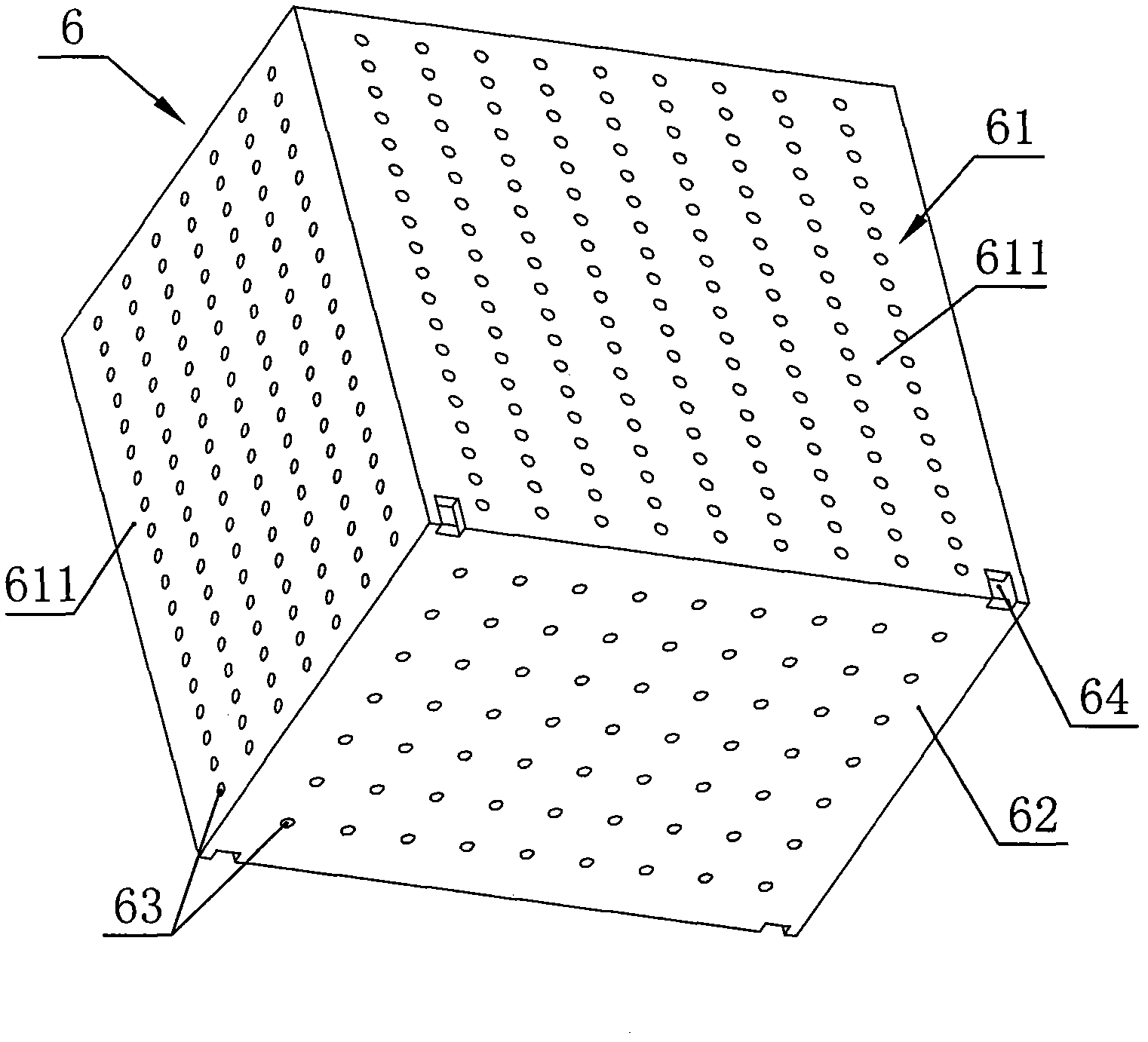

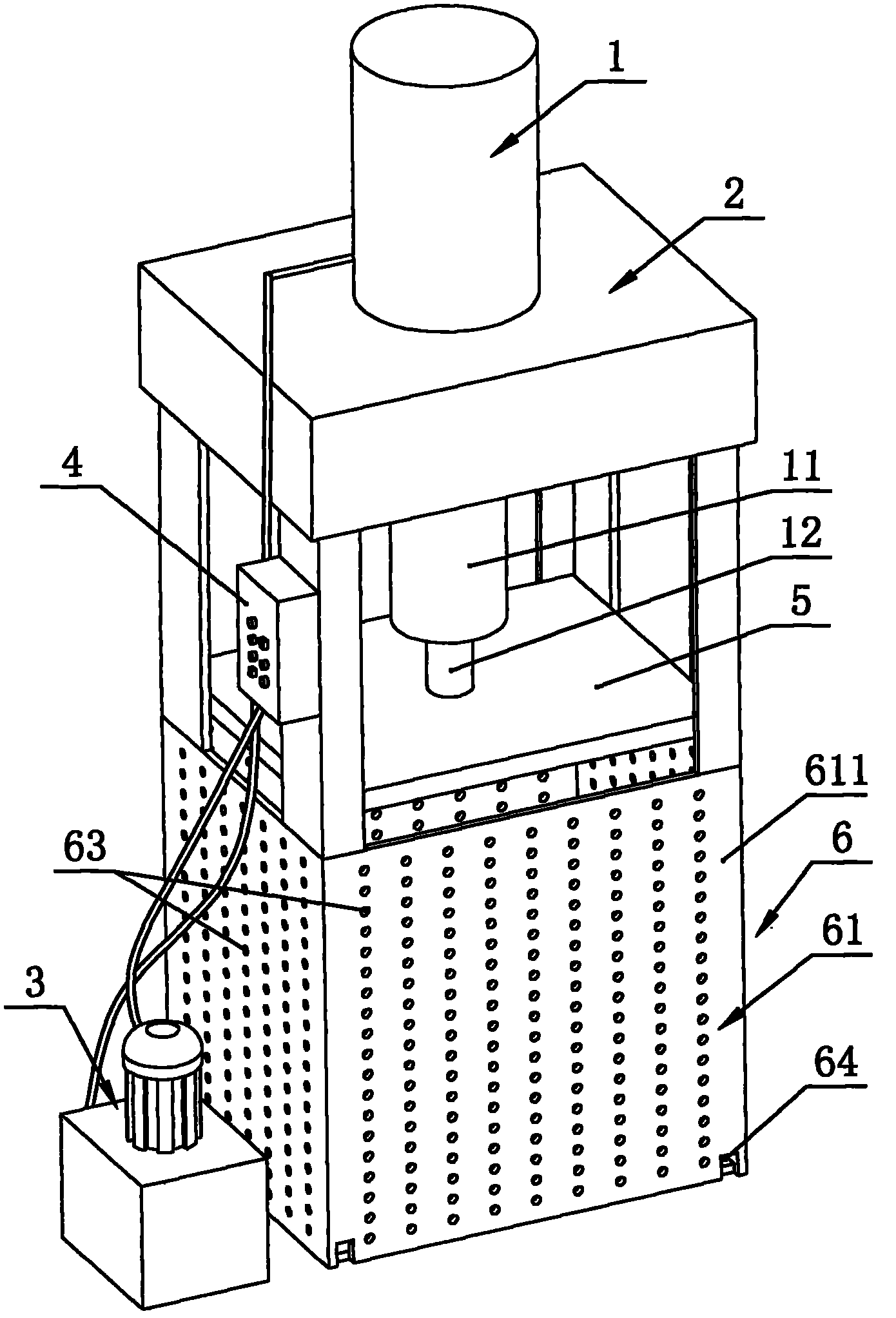

[0011] Such as figure 1 , 2 Shown is an automatic hydraulic grouting machine, including a hydraulic cylinder 1, a hydraulic cylinder base 2, a hydraulic oil pump 3 and a control device 4, the hydraulic cylinder 1 is fixed on the hydraulic cylinder base 2, and the hydraulic oil pump 3 serves as a hydraulic The power source of the oil cylinder 1, a control device 4 is provided between the hydraulic oil pump 3 and the hydraulic oil cylinder 1, the hydraulic oil cylinder 1 includes a cylinder body 11 and an output shaft 12, and the output end of the output shaft 12 is fixed with a pressure plate 5, An accommodating housing 6 is provided below the pressing plate 5, the accommodating housing 6 includes a side wall 61 and a bottom plate 62, the side wall 61 is surrounded by four side plates 611, and the side plates 611 and the bottom plate 62 are provided with several drainage holes 63 , and a plurality of drainage grooves 64 are also provided at the connection between the side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com