Vacuum agitating barrel

A technology of vacuum mixing and mixing barrels, which is applied in the direction of mixer accessories, dissolving, mixing machines, etc., and can solve problems such as uneven mixing and poor dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

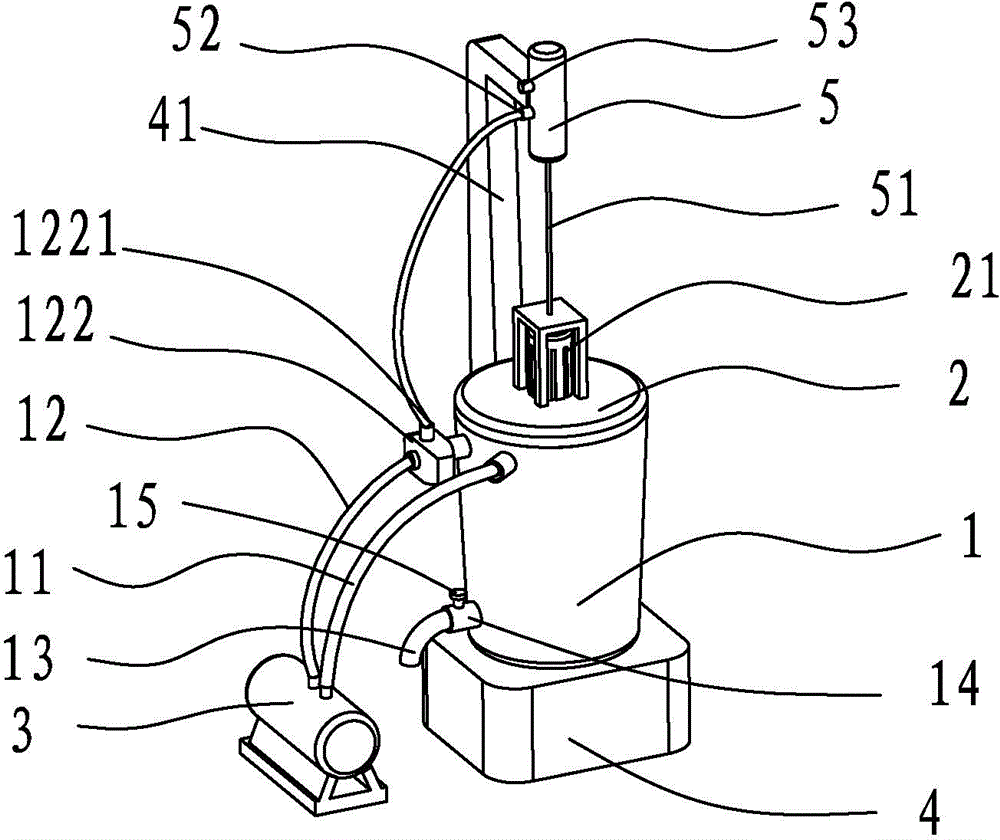

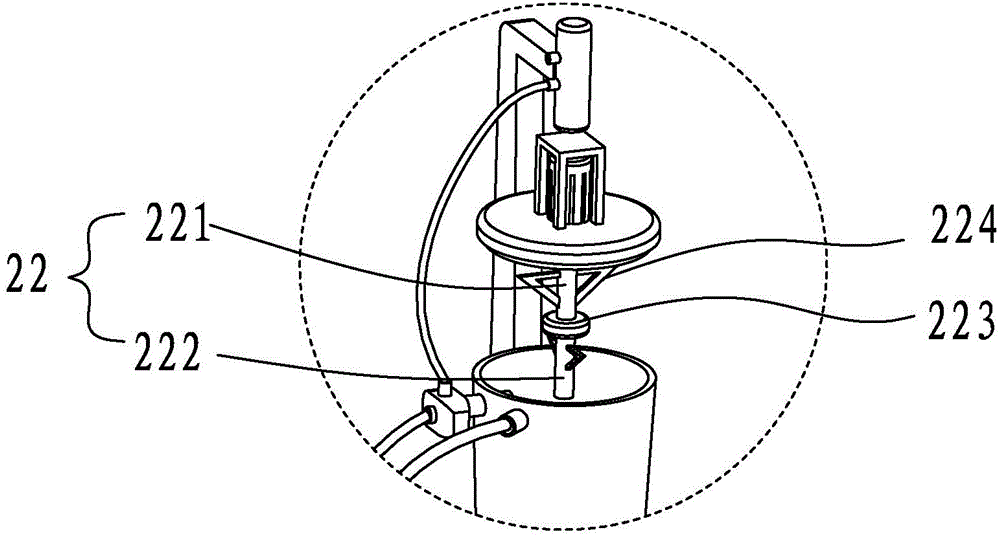

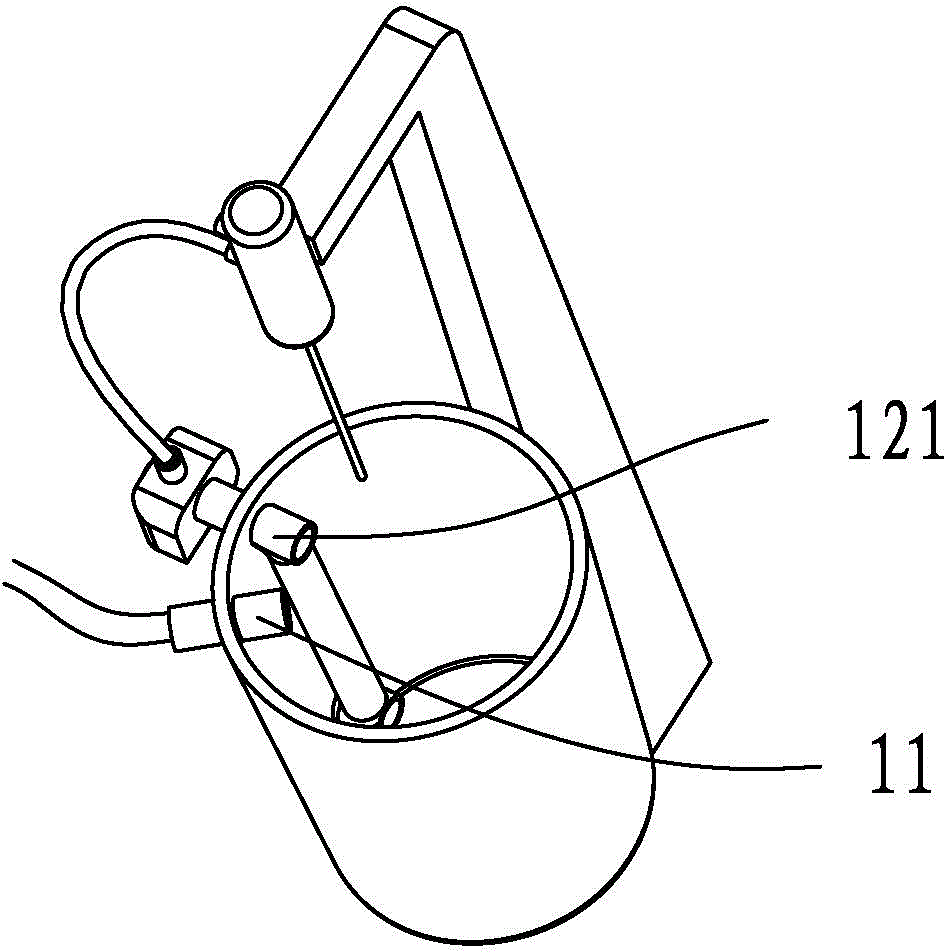

[0019] Such as Figure 1 to Figure 3 As shown, a vacuum mixing tank includes a mixing tank 1, the bottom of the mixing tank is a base, the top of the mixing tank is provided with a loam cake 2, the bottom of the loam cake is fixed with a sealing strip at the edge that is tightly closed with the mixing tank, and the top of the loam cake is provided with a There is a motor 21, a motor bracket is fixed outside the motor, a base 4 is arranged at the bottom of the mixing tank, a column 41 is fixed on the side wall of the base, and a retractable pneumatic cylinder 5 is arranged on the top of the column, and a lanyard 51 is used to connect the pneumatic cylinder and the motor bracket , the side wall of the mixing tank is provided with an air extraction pipe 11 and an air intake pipe 12, the air extraction pipe is used to remove the air in the mixing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com