3D printing device and method for molten metal

A 3D printing and molten metal technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of unstable printing process, poor surface precision of printed products, low mechanical properties of forged parts, etc., and avoid welding process. Stabilize, prevent overheating of tungsten, increase melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

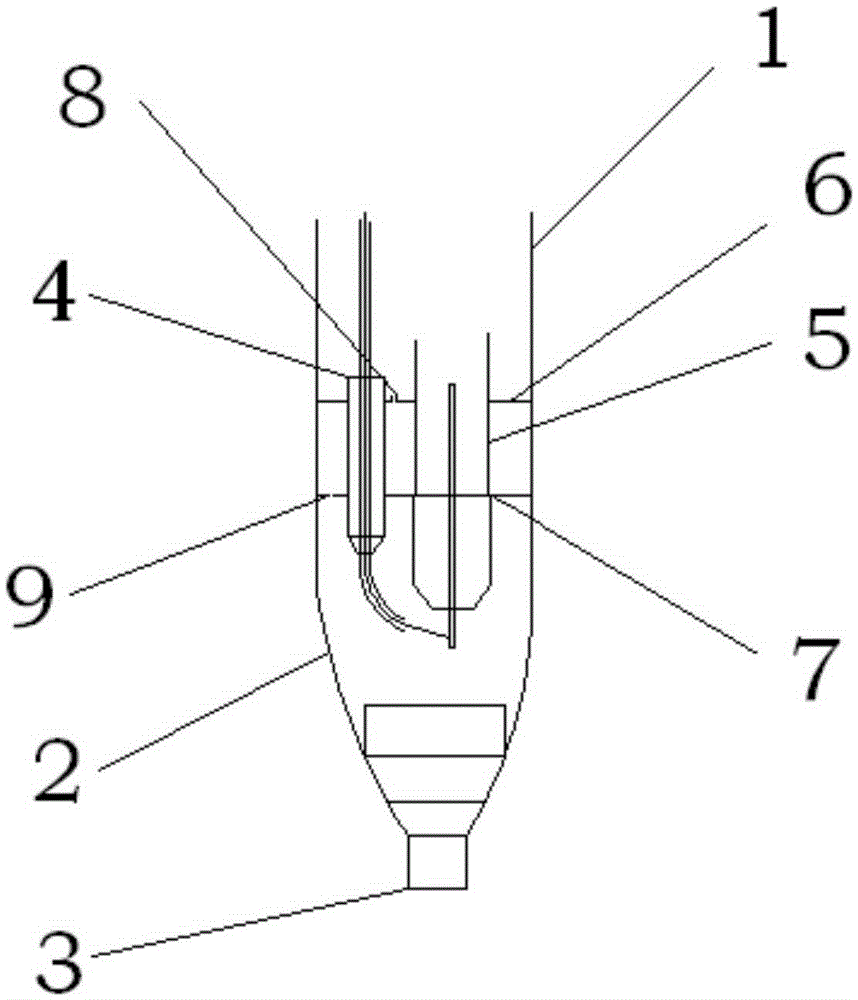

[0035] A molten metal 3D printing device, comprising a casing, a first nozzle, a melting electrode welding electrode and a non-melting electrode welding electrode, the first nozzle is connected to one end of the casing, the middle part of the casing is hollow to form a cavity, and the casing is provided with a first The sealing plate and the second sealing plate, the melting electrode welding electrode and the non-melting electrode welding electrode are located in the housing cavity, the melting electrode welding electrode and the non-melting electrode welding electrode are arranged through the two sealing plates, and the first sealing plate is provided with The gas inlet, the second sealing plate is provided with a gas outlet, and the gas inlet and the gas outlet are used to circulate inert gas. The surface area of the first sealing plate and the second sealing plate is consistent with the cross-sectional area of the housing cavity. The two sealing plates cooperate with th...

Embodiment 2

[0038]A molten metal 3D printing device, the structure of which is as described in Embodiment 1, the difference is that a water cooling device is provided outside the copper nozzle to prevent the copper nozzle from overheating.

Embodiment 3

[0040] A molten metal 3D printing device, the structure of which is as described in Embodiment 1, the difference is that one end of the first nozzle is provided with an internal thread, one end of the housing is provided with an external thread, and the first nozzle is threadedly connected with the housing. Because in 3D printing, the nozzle will be in high temperature and high pressure working state for a long time, the performance and service life of the nozzle will be affected first. The nozzle and the shell are matched and connected through internal and external threads, which is convenient for replacing the nozzle and reduces maintenance costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com