Bucket wheel mechanism suitable for lump ore stacking and taking operation

A bucket wheel, operation technology, applied in mechanically driven excavators/dredgers, transportation and packaging, loading/unloading, etc., to achieve low operating noise, improve operating efficiency, and avoid relative friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

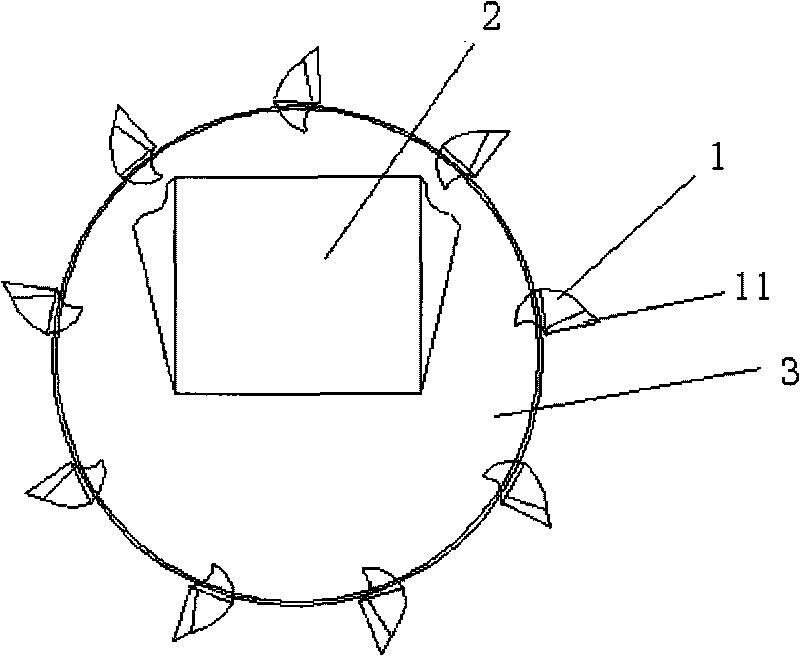

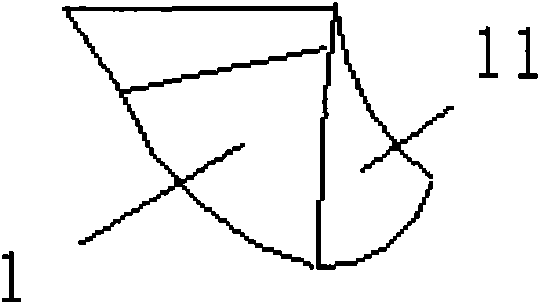

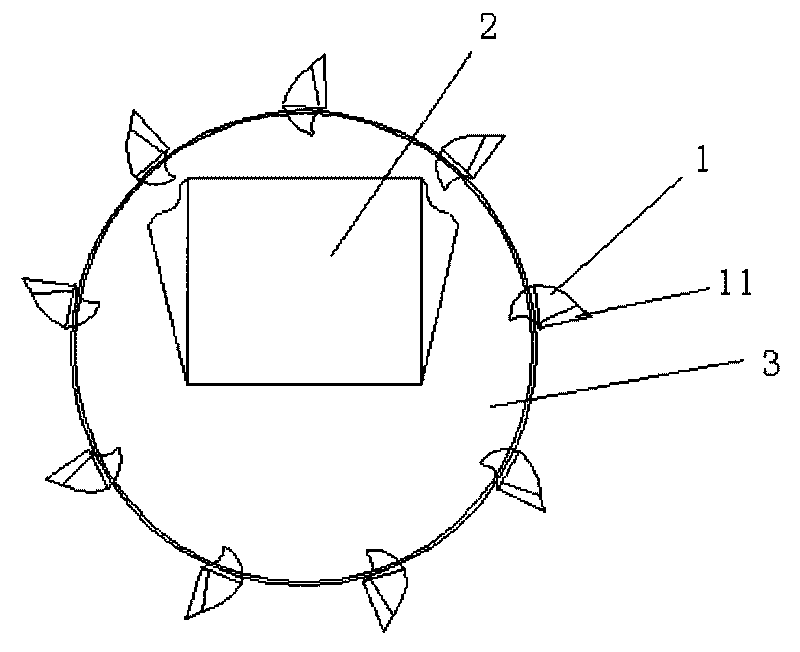

[0014] A bucket wheel machine used in lump ore stacking operations according to the present invention, the bucket wheel machine includes a bucket 1, a material receiving tank 2 and a bucket wheel body 3, and a group of buckets 1 are evenly arranged on the bucket wheel body 3 , The bucket 1 has a triangular bucket mouth 11, and bucket teeth are arranged at the triangular bucket mouth 11, and a wear-resistant and low-affinity coating is sprayed on the inside of the bucket 1; the bucket wheel body 3 is connected with an automatic control speed regulating device.

[0015] The shape of the bucket is required to not only store enough ore, but also facilitate the rapid outflow of lump ore. The speed of the bucket wheel body can be controlled, and different ores have different pile specific gravity and fluidity. The rotating speed of the bucket wheel is adjusted by the PLC automatic control system, so that the ores with different fluidities fall into the receiving tank 2 as much as po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com