High-precision lead-acid battery acid and liquid supplementing device

A technology of lead-acid battery and liquid filling device, which is applied to battery pack parts, circuits, electrical components, etc. It can solve problems such as low liquid filling accuracy, large diameter of measuring cup, and reduced accuracy of sulfuric acid electrolyte, so as to improve production efficiency , Acid outflow complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

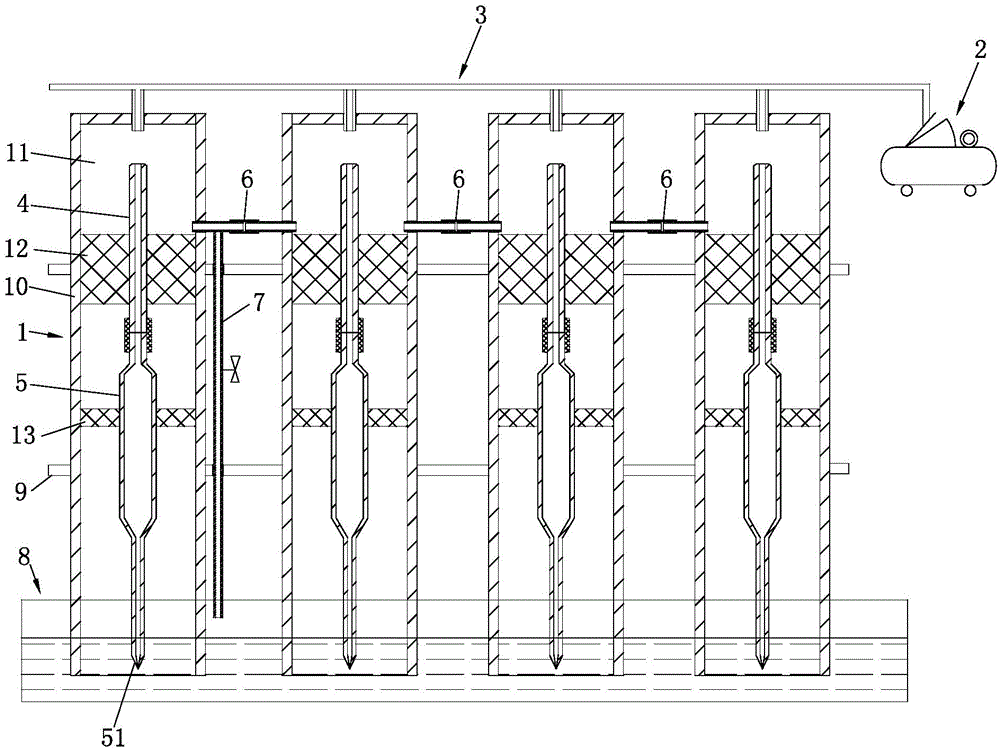

[0016] refer to figure 1 , a high-precision lead-acid battery acid filling device, including a vacuum pump 2 and four liquid addition units 4, these four liquid addition units 4 are sequentially connected through a positioning plate 9; the liquid addition unit 4 includes a cylindrical shell 10 And the quantitative injection needle tube fixed in the housing 10 through the positioning structure, the lower end of the housing 10 is open and the upper end is closed; the positioning structure includes a first positioning plug 12 and a second positioning plug 13; the quantitative injection needle tube adopts a two-stage The structure includes the first needle tube 4 and the second needle tube 5, the first positioning plug 12 fixes the first needle tube 4, and the second positioning plug 13 fixes the second needle tube 5; a reservoir is formed between the first positioning plug 12 and the closed end of the housing 10. Liquid chamber 11, the upper port of the first needle tube 4 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com