Discharging opening structure of vacuum stirring barrel

A technology of vacuum stirring and discharge port, which is used in mixer accessories, dissolving, mixer and other directions, can solve the problems of affecting the purity of finished products, increasing the contact time between materials and air, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

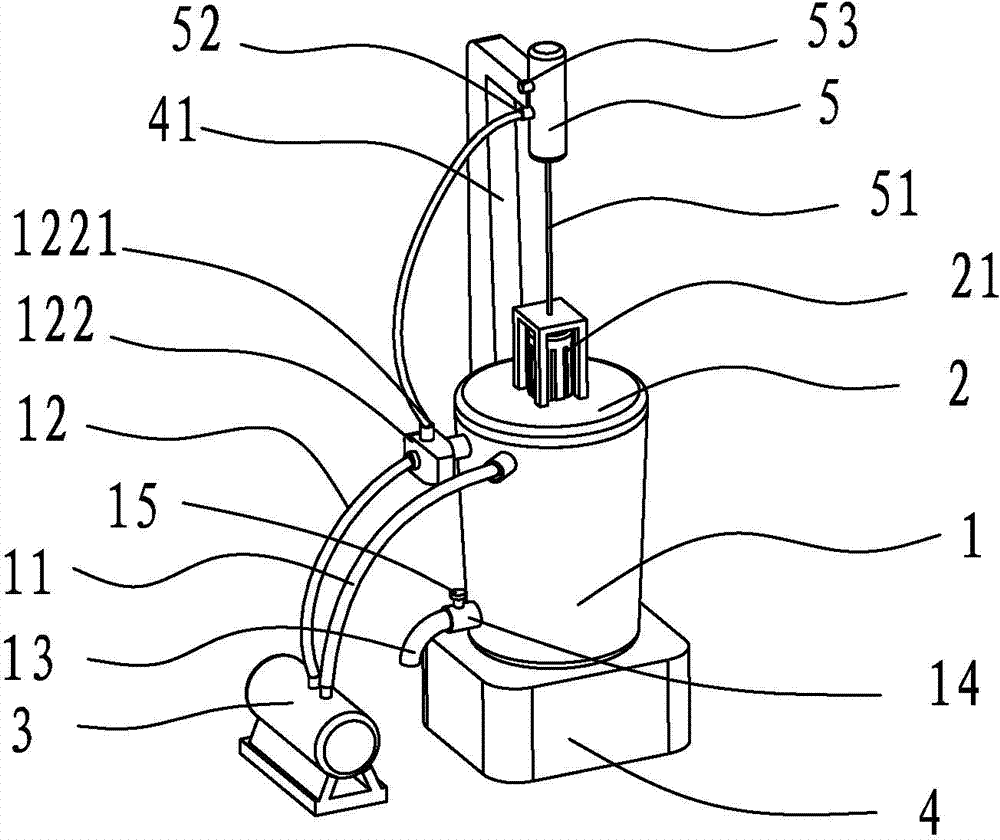

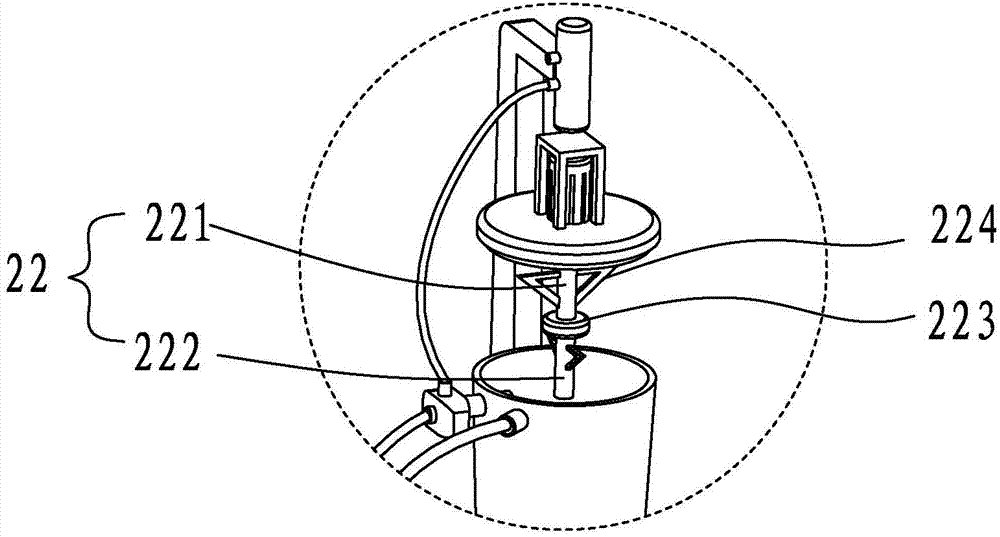

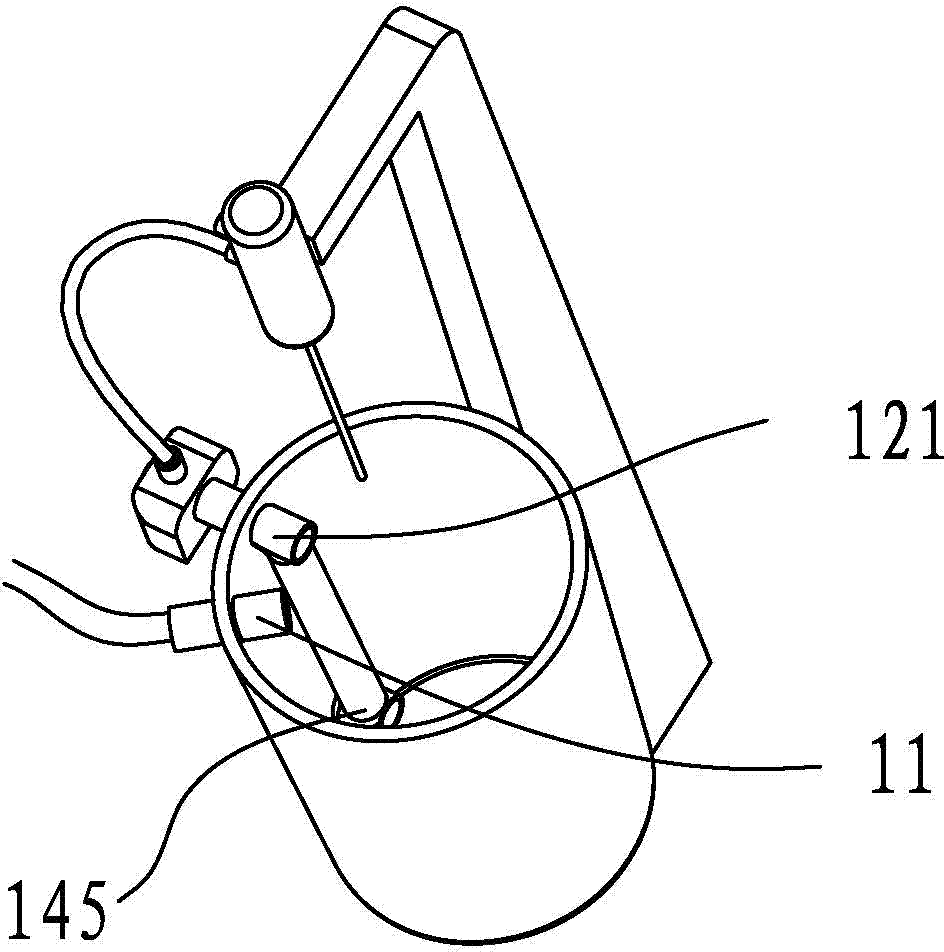

[0015] like Figure 1 to Figure 3 As shown, a discharge port structure of a vacuum mixing bucket includes a mixing bucket 1, an upper cover 2 is arranged above the mixing bucket, a sealing strip is fixed at the bottom of the upper cover at the edge tightly closed with the mixing bucket, and the top of the upper cover is provided with The motor 21 is provided with a motor bracket outside the motor, and a stirring rod 22 is provided at the bottom of the upper cover. The side wall of the mixing barrel is provided with an air suction pipe 11 and an air intake pipe 12. The air suction pipe is used to extract the air in the mixing barrel to stir the material When the material is in a vacuum environment, the air inlet pipe is used to re-inject air into the mixing barrel after the material is stirred, so that the internal air pressure is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com